Abstract

In this paper we aim to highlight the need to consider the possible role of autocatalysis in oxidation reactions when using molecular oxygen as the terminal oxidant. Oxygen in its ground state is a diradical, and depending on the reaction conditions, it can initiate oxidation through radical pathways through mechanisms which do not require the presence of a catalyst. Consequently, we contrast the oxidation of benzyl alcohol with oxidation of α-pinene. For benzyl alcohol oxidation the initial reaction is the oxidative dehydrogenation to form benzaldehyde, a non-radical process; but the subsequent over-oxidation to benzoic acid is a radical process. In this case the role of the autocatalysed reaction can be minimised. With α-pinene, the oxidation reaction is via radical pathways and now the autocatalysed reaction can be dominant and, indeed, can be the preferred pathway for the formation of high yields of the desired verbenone product.

Graphic Abstract

Similar content being viewed by others

1 Introduction

Selective oxidation is a rich area for the design of new catalysts that use molecular oxygen as the terminal oxidant will provide access to new green oxidation reactions. However, oxidation, unlike hydrogenation, can be complicated by contribution from a blank reaction, namely autocatalysis. Molecular oxygen is the preferred terminal oxidant for selective oxidation reactions, however, in its ground state it is a diradical with two unpaired electrons and consequently is paramagnetic. At ambient temperature and pressure, the radical nature of molecular oxygen has little if any influence for selective oxidation reactions. However, in some instances on raising the reaction temperature or pressure there is a marked effect on the reactivity of molecular oxygen, as now the catalyst can be an effective initiator for a non-catalysed radical chain reaction known as autocatalysis. Often these reactions exhibit an induction period in the very early stages of the oxidation reactions.

We have selected the oxidation of benzyl alcohol and α-pinene as the two reactions for investigation. Both reactions have been studied previously but in this case we contrast these oxidations using the same catalyst, namely AuPd/TiO2.

In the case of benzyl alcohol oxidation, the main product is typically benzaldehyde and the initial reaction is an oxidative dehydrogenation which does not involve a radical pathway. Indeed, benzyl alcohol is often used as a model reactant for the study of alcohol oxidation. However, the overoxidation of the initial benzaldehyde product does involve a radical pathway [1, 2].

α-pinene oxidation involves both allylic oxidation, which proceeds by a radical pathway, as well as epoxidation. α-pinene is the main component of turpentine, which is a by-product of cellulose production. The target for the oxidation of α-pinene is verbenone, a product of allylic oxidation, it is an intermediate in the production of taxol [3] and is also an intermediate for fragrances and flavours. The other product of allylic oxidation, verbenol, and the product of epoxidation, pinene oxide, have less value and so it is important to identify synthetic strategies to verbenone. Many studies have used hydrogen peroxide or peroxides as the oxidant, rather than oxygen [4,5,6], but molecular oxygen is the preferred terminal oxidant. However, the oxidation of α-pinene with oxygen has not been intensively investigated. Cobalt complexes have been studied [7, 8], but the reaction can be very slow, taking several days with limited selectivity to verbenone [7] and α-pinene oxide is the main product. Recently carbon nanotubes [9] have been used, but with these catalysts α-pinene oxide is the main product and there is limited selectivity to verbenone, particularly when Co and Mn additives are used. Interestingly, the uncatalyzed autoxidation of α-pinene to verbenone was observed by Moore et al. [10] in 1955. In their work α-pinene was autoxidised in the dark at 100 °C, after 160 min the conversion was 65%, but the main products were verbenol and α-pinene epoxide and only 9% selectivity to verbenone was observed. Another study of autoxidation also reported a very low verbenone yield [11].

The oxidation of benzyl alcohol has been studied with the AuPd/TiO2 [1] catalyst but α-pinene oxidation has not been studied previously with this catalyst. In this paper we contrast the oxidation of benzyl alcohol and α-pinene using the same catalyst, to explore the possible role of autocatalysis.

2 Experimental

2.1 Catalyst Synthesis

The 2.5 wt% Pd + 2.5 wt% Au/TiO2 used in this study [1, 12, 13] was prepared by impregnation of TiO2 (Evonik, P25) via an incipient wetness method using aqueous solutions of PdCl2 (Johnson Matthey) and HAuCl4·3H2O (Johnson Matthey). The detailed procedure was as follows. An aqueous solution of HAuCl4·3H2O [10 ml, 5 g dissolved in water (250 ml)] and an aqueous solution of PdCl2 [4.15 ml, 1 g in water (25 ml)] were simultaneously added to TiO2 (3.8 g). The paste formed was dried at 80 °C for 16 h and calcined in static air at 400 °C for 3 h. This catalyst has been extensively characterised previously and comprises a broad range of AuPd nanoparticles (2–40 nm in diameter), with the small nanoparticles being Pd rich and the larger particles being Au rich with a Au rich core and a Pd rich shell [13].

2.2 Benzyl Alcohol Oxidation

The standard reaction conditions are described as follows. Catalyst testing was performed using an Autoclave Engineers stainless steel autoclave (Autoclave Engineers Inline MagneDrive III) with a nominal volume of 100 ml and a maximum working pressure of 2000 psi. The vessel was charged with benzyl alcohol (40 ml, Fluka, 98%) and catalyst (25 mg). The autoclave was then purged three times with oxygen leaving the vessel at the desired pressure. The pressure was maintained constant throughout the experiment, as the oxygen was consumed in the reaction it was replenished. The stirrer speed was 1500 rpm and the reaction mixture was raised to the required temperature and maintained. Samples from the reactor were taken periodically via a sampling pipe, ensuring that the volume purged before sampling was higher than the tube volume, and analysed by gas chromatography using a CP-Wax column. As the reactions are conducted within the autoclave they are carried out in the dark and hence there is no potential contribution from photocatalysis resulting from the plasmon resonance of the metal nanoparticle in combination with the TiO2 support.

2.3 α-Pinene Oxidation

The standard reaction conditions are described as follows. α-pinene oxidation was performed using a Parr Instruments stainless steel autoclave with a nominal volume of 50 ml and a maximum working pressure of 3000 Psi. The vessel was charged with α-pinene (40 ml, 0.25 mol, Fluka 98%) and catalyst (50 mg). The autoclave was then purged 3 times with oxygen leaving the vessel at the desired pressure. The pressure was maintained constant throughout the experiment with oxygen consumed in the reaction being replenished. The stirrer speed was set at 1500 rpm and the reaction mixture was raised to and maintained at the required temperature of 75 °C. Samples from the reactor were taken periodically via a sampling pipe, ensuring that the volume purged before sampling was higher than the tube volume, and analysed by gas chromatography using a CP-Wax column. As the reactions are conducted within the autoclave they are carried out in the dark and hence there is no potential contribution from photocatalysis resulting from the plasmon resonance of the metal nanoparticle in combination with the TiO2 support.

3 Results and Discussion

3.1 Oxidation of Benzyl Alcohol

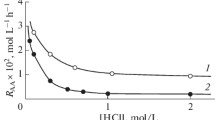

The oxidation of benzyl alcohol was studied at 100 °C using the standard reaction conditions and the conversion for the catalysed reaction and the reaction in the absence of catalyst is shown in Fig. 1. At this temperature the blank non-catalysed reaction is negligible and there is a distinct difference for the conversion when the catalyst is present. Indeed, for benzyl alcohol oxidation the blank non-catalysed reaction is not significant until 160 °C (Fig. 2). At all reaction temperatures the main product is benzaldehyde and the selectivity to benzaldehyde is a function mainly of benzyl alcohol conversion (Fig. 3). However, as we have previously shown at 100 °C, by increasing the catalyst amount and at increased reaction times with this catalyst, it is possible to achieve a yield of 96% benzaldehyde [1]. At this temperature the radical pathway that would rapidly convert benzaldehyde to benzoic acid is prevented by benzyl alcohol acting as a radical inhibitor, and whilst even small amounts remain unreacted the benzaldehyde is not over-oxidised. However, at higher temperatures the effect becomes less prominent, and benzoic acid is formed in increasing amounts, particularly at 160 °C. It should be noted that the catalysed conversion of benzyl alcohol at 100 or 160 °C does not show any induction period; whereas the non-catalysed reaction at 160 °C shows a pronounced induction period, during which a radical species is generated that can initiate the oxidation with molecular oxygen. The catalysed oxidative dehydrogenation pathway does not require the generation of such a species and so no induction period is observed. Decreasing the oxygen partial pressure at a reaction temperature of 160 °C decreases the conversion (Fig. 4), and using 1 bar O2 the blank reaction can also be minimised. Hence with benzyl alcohol it is possible to observe a catalysed oxidation reaction that is more significant than the blank non-catalysed reaction using a broad range of reaction conditions, and as noted previously using the catalyst very high yield to benzaldehyde can be achieved.

3.2 α-Pinene Oxidation

α-pinene is a more reactive substrate than benzyl alcohol and consequently we studied the oxidation at 75 °C using 1, 10 and 20 bar O2. At this temperature appreciable conversions could be achieved over a 24 h reaction period. However, the addition of the AuPd/TiO2 made no difference to the conversion as the autocatalysed reaction was dominant. Table 1 shows the initial rates for α-pinene oxidation at different O2 pressures measured at 4 h reaction time. At this time the conversion is very low (1–2%) and the selectivity to verbenone is also low at ca. 20%. As the reaction proceeds the α-pinene conversion increases in an exponential way that is typical of an autocatalysed reaction, and consequently the rate at 24 h reaction is increased (Table 1) and the selectivity to verbenone also increased to 80%. Increasing the O2 pressure increased the conversion and using a pressure of 30 bar O2 (Fig. 5) a conversion of over 80% was observed and the addition of catalyst had no marked effect. The selectivity to verbenone was 85% in the absence of the catalyst and was decreased slightly when the catalyst was present to ca. 80%. It is therefore clear that for the oxidation of α-pinene the AuPd/TiO2 catalyst has no effect and the autocatalysed reaction is dominant. In many studies of the oxidation of substrates such as this the blank non-catalysed reaction is often not reported, and yet as we have demonstrated here this pathway cannot be ignored when allylic oxidation is considered.

We have previously studied the oxidation of linear alkenes [14] and for these reactions a similar induction period is observed, although now with these less reactive substrates the autocatalysed reaction is less dominant. For linear alkenes, an exponential growth in conversion is observed after the initial induction period, during which time a radical species is formed in a slow primary reaction, which then acts as a radical chain initiator for the propagation of the reaction. The catalyst is required for this initial reaction and in its absence the overall reaction is much slower, but in effect the catalyst is acting as an initiator. Most recently we have studied the allylic oxidation of cyclic alkenes with graphitic oxide [15]. While the presence of graphitic oxide increases the conversion compared with the blank reaction, both blank and catalysed reaction followed the same conversion verses selectivity trend, indicating that in this case the graphitic oxide is acting as an initiator for the allylic oxidation reaction.

Previously we have examined autoxidation and its role on the catalytic aerobic oxidation of cinnamyl alcohol, another allylic oxidation, using similar catalysts of supported AuPd nanoparticles prepared using either sol-immobilisation or incipient wetness impregnation [16, 17]. In this detailed study we demonstrated that by selection of the catalyst and the reaction conditions the autoxidation process can be inhibited, or the two processes, namely catalytic oxidation and autoxidation, can coexist. Hence, judicious catalyst design can enable different product distributions to be obtained. In this case the catalyst prepared by the sol-immobilisation method prevented autoxidation, leaving the catalytic process dominant; whereas catalysts prepared by impregnation enabled both the catalytic process and autoxidation to occur simultaneously.

As verbenone at high conversion is observed with high selectivity it is important to consider the possible reaction mechanism by which this is achieved. Cao et al. [9] studied the mechanism of the aerobic oxidation of α-pinene using carbon nanotubes as a catalyst. They demonstrated several pathways are possible. In their case the major product was α-pinene oxide. Verbenone and verbenyl alcohol were also formed in similar quantities. This is consistent with verbenone and verbenyl alcohol being formed from a verbenyl hydroperoxide intermediate, as these hydroperoxides are known to react to form the ketone and the alcohol as a 1:1 mixture [18]. With the autocatalysed reaction of α-pinene we observe the ketone and the alcohol as a 4:1 mixture at high conversion and clearly their formation does not proceed solely through the formation of a verbenyl hydroperoxide intermediate and therefore another, as yet unidentified reaction pathway is present for the autocatalysed process.

4 Conclusions

When investigating selective oxidation reactions, it is important to consider the nature of the possible reaction pathways especially when allylic oxidation is considered. It is important to determine the nature of the blank uncatalyzed reaction rather than just concentrating on the catalysed reaction. This is necessary as the non-catalysed reaction can be dominant, as we have shown to be the case with α-pinene oxidation. Indeed, for α-pinene oxidation the addition of the AuPd/TiO2 catalyst has no effect on conversion and can have a detrimental effect on the selectivity to the desired verbenone product. We have shown that using the autocatalysed reaction at high O2 pressure is more effective for maximising the verbenone yield and it is clearly important that the autocatalysed reaction is considered in such cases.

References

Enache DI, Edwards JK, Landon P, Solsona-Espriu B, Carley AF et al (2006) Solvent-free oxidation of primary alcohols to aldehydes using titania-supported gold-palladium catalysts. Science 311:362–365

Sankar M, Nowicka E, Carter E, Murphy DM, Knight DW et al (2014) The benzaldehyde oxidation paradox explained by the interception of peroxy radical by benzyl alcohol. Nature Commun 5:3332

Wender PA, Mucciaro TP (1992) A new and practical approach to the synthesis of taxol and taxol analogs: the pinene path. J Am Chem Soc 114:5878–5879

Lajunen MK, Maunulab T, Koskinen AMP (2000) Co(II) catalysed oxidation of α-pinene by molecular oxygen part 2. Tetrahedron 56:8167–8171

McMorn P, Roberts G, Hutchings GJ (2000) Oxidation of α-pinene to verbonone using silica-titania co-gel catalyst. Catal Lett 67:203–206

Romanenko EP, Taraban EA, Tkachev AV (2006) Catalytic oxidation of α-pinene with tert-butyl hydroperoxide in the presence of Fe-pillared montmorillonite. Russ Chem Bull 55:993–998

Lajunen M, Koskinen AMP (1994) Co(II)-catalysed allylic oxidation of α-pinene by molecular oxygen; synthesis of verbenone. Tet Lett 35:4461–4464

Chakrabarty R, Das BK, Clark JH (2007) Enhanced selectivity in green catalytic epoxidation using a supported cobalt complex. Green Chem 9:845–848

Cao Y, Li Y, Yu H, Peng F, Wang H (2015) Aerobic oxidation of α-pinene catalyzed by carbon nanotubes. Catal Sci Technol 5:3935–3944

Moore RN, Golumbic C, Fisher CS (1956) Autoxidation ofα-pinene. J Am Chem Soc 78:1173–1176

Lajunen MK (2001) Co(II) catalysed oxidation of α-pinene by molecular oxygen: Part III. J Mol Catal A 169:33–40

Edwards JK, Solsona B, Landon P, Carley AF, Herzing A et al (2005) Direct synthesis of hydrogen peroxide from H2 and O2 using TiO2-supported Au-Pd catalysts. J Catal 236:69–79

Hutchings GJ, Kiely CJ (2013) Strategies for the synthesis of supported gold palladium nanoparticles with controlled morphology and composition. Acc Chem Res 46:1759–2177

Gupta UN, Alshammari H, Dummer NF, Jenkins RL, Bethell D et al (2015) Solvent-free oxidation of dec-1-ene using gold/graphite catalyst using an in situ generated oxidant. Catal Sci Technol 5:1307–1313

Pattisson S, Rogers O, Whiston K, Taylor SH, Hutchings GJ (2020) Low temperature solvent-free allylic oxidation of cyclohexene using graphitic oxide catalysts. Catal Today 357:3–7

Rucinska E, Pattisson S, Miedziak PJ, Brett GL, Morgan DJ et al (2020) Cinnamyl alcohol oxidation using supported bimetallic au-pd nanoparticles: an optimization of metal ratio and investigation of the deactivation mechanism under autoxidation conditions. Top Catal 63:99–102

Rucinska E, Miedziak PJ, Pattisson S, Brett GL, Iqbal S et al (2018) Cinnamyl alcohol oxidation using supported bimetallic Au-Pd nanoparticles: an investigation of autoxidation and catalysis. Catal Sci Technol 8:2987–2997

Liu X, Conte M, Weng W, He Q, Jenkins RL et al (2015) Molybdenum blue nano-rings: an effective catalyst for the partial oxidation of cyclohexane. Catal Sci Technol 5:217–227

Acknowledgements

We thank Vertellus for financial support for PJM.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Miedziak, P.J., Pattisson, S., Edwards, J.K. et al. The Over-Riding Role of Autocatalysis in Allylic Oxidation. Catal Lett 152, 1003–1008 (2022). https://doi.org/10.1007/s10562-021-03707-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-021-03707-4