Abstract

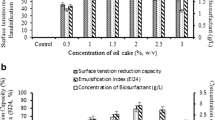

Biosurfactant production by Pseudomonas aeruginosa EBN-8 mutant was studied in shake flasks on separate wastes from canola, soybean and corn oil refineries. Of the substrates tested, canola oil refinery waste (COD=20 g l−1) supplemented with sodium nitrate (at COD/N=20) showed the best microbial growth (4.50 g l−1) and rhamnolipid production (8.50 g l−1), at 10 d of incubation with the specific growth rate of 0.316 h−1 and specific product yield of 0.597 g g−1 h. Its cell-free supernatant showed the critical micelle dilution (CMD) of 150 and surface tension (ST) of 28.5 mN m−1.

Similar content being viewed by others

References

Abalos A, Maximo F, Manresa MA, Bastida J (2002) Utilization of response surface methodology to optimize the culture media for the production of rhamnolipids by Pseudomonas aeruginosa AT10 J. Chem. Technol. Biotechnol. 77:777–784

Abalos A, Pinazo A, Infante MR, Casals M, Garcia F, Manresa A (2001) Physicochemical and antimicrobial properties of new rhamnolipids produced by Pseudomonas aeruginosa AT10 from soybean oil refinery wastes Langmuir 17: 1367–1371

Aiba S, Humphrey AE, Millis NF (1973) Biochemical Engineering Academic Press, New York pp. 75–106

Babu PS, Vaidya AN, Bal AS, Kapur R, Juwarkar A, Khanna P (1996) Kinetics of biosurfactant production by Pseudomonas aeruginosa BS2 from industrial wastes Biotechnol. Lett. 18:263–268

Benincasa M, Abalos A, Oliveira I, Manresa A (2004) Chemical structure, surface properties and biological activities of the biosurfactant produced by Pseudomonas aeruginosa LBI from soapstock Antonie van Leeuwenhoek 85:1–8

Bushnell LD, Hass HF (1941) Utilization of certain hydrocarbons by microorganisms J. Bacteriol. 41:653–658

Desai JD, Banat IM (1997) Microbial production of surfactants and their commercial potential Microbiol. Mol. Biol. Rev. 61:47–64

Dubey K, Juwarkar A (2001) Distillery and crud whey wastes as viable alternative sources for biosurfactant production World J. Microbiol. Biotechnol. 17:61–69

Georgiou G, Nil SC, Sharma MM (1992) Surface-active compounds from microorganisms BioTechnol. 10:60–65

Haba E, Espuny MJ, Busquets M, Manresa A (2000) Screening and production of rhamnolipids by Pseudomonas aeruginosa 47T2 NCIB 40044 from waste frying oils J. Appl. Microbiol. 88:379–387

Haba E, Pinazo A, Jauregui O, Espuny MJ, Infante MR, Manresa A (2003) Physicochemical and antimicrobial properties of rhamnolipids produced by Pseudomonas aeruginosa 47T2 NCBIM 40044 Biotechnol. Bioeng. 81:316–322

Iqbal S, Khalid ZM, Malik KA (1995) Enhanced biodegradation and emulsification of crude oil and hyperproduction of biosurfactants by a gamma ray-induced mutant of Pseudomonas aeruginosa Lett. Appl. Microbiol. 21:176–179

Makkar RS, Cameotra SS (1999) Biosurfactant production by microorganisms on unconventional carbon sources J. Surf. Det. 2:237–241

Martinez-Moreno JM (1972) Carateristas fisico-quimius de alpechines. In: Fundamentos Fisico-Quimicos de la Tecnica Oleicola. Consejo Superior de Investigaciones Cientifial, Madrid

Mercade ME, Manresa MA (1994) The use of agroindustrial by-products for biosurfactant production J. Am. Oil Chem. Soc. 71:61–64

Mercade ME, Manresa MA, Robert M, Espuny MJ, de Andes C, Guinea J (1993) Olive oil mill effluents (OOME). New substrate for biosurfactant production Biores. Technol. 43:1–6

Rahman KSM, Rahman TJ, McClean S, Marchant R, Banat IM (2002) Rhamnolipid biosurfactant production by strains of Pseudomonas aeruginosa using low-cost raw materials Biotechnol. Prog. 18:1277–1281

Robert M, Mercade ME, Bosch MP, Parra JL, Espuny MJ, Manresa MA, Guinea J (1989) Effect of carbon source on biosurfactant production by Pseudomonas aeruginosa 44T1 Biotechnol. Lett. 11:871–874

Sim L, Ward OP, Li Z-Y (1997) Production and characterization of a biosurfactant isolated from Pseudomonas aeruginosa UW-1. J. Ind. Microbiol. Biotechnol. 19:232–238

Vipulanandan C, Ren X (2002) Enhanced solubility and biodegradation of naphthalene with biosurfactant J. Environ. Eng. 126:629–634

Zhang Y, Miller RM (1995) Effect of rhamnolipid (biosurfactant) structure on solubilization and biodegradation of n-alkanes Appl. Environ. Microbiol. 61:2247–2251

Acknowledgements

The authors acknowledge the Higher Education Commission, Islamabad for funding for this research, Ch. Muhammad Akram, General Manager, Madni Ghee Mills, Faisalabad for providing the VORWs samples and Mr. Muhammad Afzal, Senior Scientist, NIBGE for his lab’s facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Raza, Z.A., Rehman, A., Khan, M.S. et al. Improved production of biosurfactant by a Pseudomonas aeruginosa mutant using vegetable oil refinery wastes. Biodegradation 18, 115–121 (2007). https://doi.org/10.1007/s10532-006-9047-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-006-9047-9