Abstract

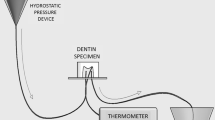

The neodymium/yttrium–aluminum–garnet (Nd/YAG) laser has been suggested to repair broken prostheses in the mouth. This study investigated the effects of different dentin thicknesses and air cooling on pulpal temperature rise during laser welding. Three intact human maxillary molars were prepared for full-veneer crown. For each tooth, dentin thicknesses in mesiobuccal cusp was 2, 3, or 4 mm. Twenty dies were duplicated from each of the prepared teeth. For metal copings with 0.5-mm thickness, wax patterns were prepared with dip wax technique directly onto each of dies. All patterns were sprued and invested. The castings were made using a nickel–chromium alloy (Nicromed Premium, Neodontics). A hole with 0.5-mm diameter was prepared on the mesiobuccal cusp of each crown. The Nd/YAG laser (9.85 W; 1 Hz repetition rate; fluence, 1.230 J/cm2; Fidelis Plus 3, Fotona) was used for welding with or without air cooling (n = 10). The temperature rise was measured in pulpal chamber with a J-type thermocouple wire that was connected to a data logger. Differences between start and highest temperature reading were taken, and temperature rise values were compared using two-way analysis of variance and Tukey’s honestly significant difference tests (α = .05). Pulpal temperature rise varied significantly depending on the dentin thickness and air cooling (p < 0.05). The non-air cooling group induced significantly the highest temperature increases. There were no significant differences between 2- and 3-mm dentin thicknesses groups (p > 0.05); however, pulpal temperature rise was the lowest for 4-mm dentin thickness group (p < 0.05). The highest values of thermal increase were found in the pulp chamber (6.8°C) when no air cooling was used in 2-mm dentin thickness group. Laser welding on base metal castings with Nd/YAG laser can be applied with air cooling to avoid temperature rises known to adversely affect pulpal health when dentin thickness is 2 or 3 mm.

Similar content being viewed by others

References

Powers JM, Sakaguchi RL (2006) Craig’s restorative dental materials: properties, 12th edn. Elsevier, St. Louis, p 375

Shimakura M, Yamada S, Takeuchi M, Miura K, Ikeyama J (2009) Influence of irradiation conditions on the deformation of pure titanium frames in laser welding. Dent Mater J 28:243–247

Kakimoto K (1988) Basic study on laser welding of Ag–Pd–Cu–Au alloy. Part 3. Factors on mechanical properties. J Jpn Prosthodont Soc 32:62–73

Kakimoto K, Moriguchi A, Uenishi K, Komasa Y, Gonda Y (2001) Laser weldability of dental cobalt chromium alloy. Shika Igaku 64:35–47

Fornaini C, Passaretti F, Villa E, Rocca JP, Merigo E, Vescovi P, Meleti M, Manfredi M, Nammour S (2011) Intraoral laser welding: ultrastructural and mechanical analysis to compare laboratory laser and dental laser. Lasers Med Sci 26:415–420

Fornaini C, Bertrand C, Bonanini M, Rocca JP, Nammour S (2009) Welding in the dental office by fiber-delivered laser: a new technique. Photomed Laser Surg 27:417–423

Fornaini C, Vescovi P, Merigo E, Rocca JP, Mahler P, Bertrand C, Nammour S (2010) Intraoral metal laser welding: a case report. Lasers Med Sci 25:303–307

Coluzzi DJ (2004) Fundam Dent Lasers Sci Instrum 48:751–770

Shin C, Miura H, Okada D, Yamazaki A (2006) Accuracy of temporary laser welding of FPDs by Nd:YAG laser in the oral cavity. Dent Mater J 25:604–610

Degidi M, Gehrke P, Spanel A, Piattelli A (2006) Syncrystallization: a technique for temporization of immediately loaded implants with metal-reinforced acrylic resin restorations. Clin Imp Dent Res 8:123–134

Degidi M, Nardi D, Piattelli A (2009) Immediate rehabilitation of the edentulous mandible with a definitive prosthesis supported by an intra-oral welded titanium bar. Int J Oral Maxillofac Imp 24:342–347

Degidi M, Nardi D, Piattelli A (2010) Prospective study with a 2-year follow-up on immediate implant loading in the edentulous mandible with a definitive restoration using intra-oral welding. Clin Oral Imp Res 21:379–385

Degidi M, Nardi D, Piattelli A (2008) Immediate loading of the edentulous maxilla with a final restoration supported by an intraoral welded titanium bar: a case series of 20 consecutive cases. J Periodontol 79:2207–2213

Fornaini C, Bertrand C, Rocca JP, Mahler P, Bonanini M, Vescovi P, Merigo E, Nammour S (2010) Intra-oral laser welding: an in vitro evaluation of thermal increase. Lasers Med Sci 25:473–477

Pohto M, Scheinin A (1958) Microscopic observations on living dental pulp. Acta Odontol Scand 16:303–327

Zach L, Cohen C (1965) Pulp response to externally applied heat. Oral Surg Oral Med Oral Pathol 19:515–530

Acknowledgment

The authors would like to thank Fotona Company (Ljubljana, Slovenia) for providing special hand pieces for the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Secilmis, A., Bulbul, M., Sari, T. et al. Effects of different dentin thicknesses and air cooling on pulpal temperature rise during laser welding. Lasers Med Sci 28, 167–170 (2013). https://doi.org/10.1007/s10103-012-1108-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10103-012-1108-1