Abstract

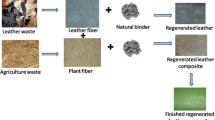

Preparation of composite materials with better mechanical properties and agreeable use is a need of the time for the reason that it is eco-friendly. Having this objective in mind, the work of preparing value-added leather composites using finished leather waste and various plant fibers as raw materials is done in the laboratory of Council of Scientific and Industrial Research–Central Leather Research Institute, India. In the leather goods and footwear manufacturing industries, about 20–30% of leather is discarded as waste, and presently it is imperative to make effort to utilize this waste in Ethiopia because it is huge and untapped resource. The recycled leather (RCL) as control and its composite boards (CBs) which are the mixtures of leather fibers with plant fibers like jute (Corchorus trilocularis L.), hibiscus (Hibiscus cannabinus), sisal (Agave sisalana), palm (Phoenix dactylifera) and enset (Ensete ventricosum) in the proportion of 10, 20, 30, and 40% are characterized for their physicochemical properties (tensile strength, elongation at break, stitch tear strength, water absorption, water desorption, and flexing strength), scanning electron microscope (SEM), Fourier transform infrared, thermogravimetric analysis (TGA), and differential scanning calorimeter (DSC). Composites exhibited better mechanical properties compared to those of control boards. SEM pictures showed the composite nature of the boards. TGA studies revealed better thermal stability for composites. In the DSC study, the CBs of RCL-S and RCL-P exhibited higher melting point values than those of RCL-J, RCL-H, and RCL-E samples. Based on these results, all the composite boards may be used as raw material for the preparation of consumer products such as insoles, chapel-uppers, wallets, light hand bags, mouse pads, roofing, wall partitioning, and components of furniture and interior decorations.

Similar content being viewed by others

References

Asfaw N, Mohamed J (2007) Livestock ownership, commercial off-take rates and their determinants in Ethiopia. Final draft

Assamoi B, Lawryshyn Y (2012) The environmental comparison of land filling vs. incineration of MSW accounting for waste diversion. Waste Manag 32:1019–1030

CSA (2013) Agricultural Sample Survey, 2012/13 (2005 E.C.), volume II: report on livestock and livestock characteristics (Private peasant holdings). Statistical Bulletin 570. Central Statistical Agency (CSA), Federal Democratic Republic of Ethiopia, Addis Ababa

Flandez J, Gonzalez I, Resplandis JB, EI Mansouri NE, Vilaseca F, Mutje P (2012) Management of corn stalk waste as reinforcement for polypropylene injection moulded composites. BioResources 7:1836–1849

Gurram R, Al-Shannag M, Knapp S, Das T, Singsaas E, Alkasrawi M (2016) Technical possibilities of bioethanol production from coffee pulp: a renewable feedstock. Clean Technol Environ Policy 18:269–278

Herakovich CT (1998) Mechanics of fibrous composites. Wiley, New York. http://www.sciencedirect.com/science/journal/13598

John Sundar V, Raghavarao J, Muralidharan C, Mandal AB (2011) Recovery and utilization of chromium-tanned proteinous wastes of leather making: a review. Crit Rev Environ Sci Technol 41(22):2048–2075. doi:10.1080/10643389.2010.497434

Kalia S, Thakur K, Celli A, Kiechel MA, Schauer CL (2013) Surface modification of plant fibers using environment friendly methods for their application in polymer composites, textile industry and antimicrobial activities: a review. J Environ Chem Eng 1:97–112

Kanagaraj J, Velappan KC, Chandrababu NK, Sadulla S (2006) Solid waste generation in the leather industries and its utilization for cleaner environment—a review. J Sci Ind Res 65:541–548

Karthik T, Murugan R (2013) Characterization and analysis of ligno-cellulosic seed fiber from Pergularia daemia plant for textile applications. Fibers Polym 14(3):465–472

Ku H, Wang H, Pattarachaiyakoop N, Trada M (2011) A review on the tensile properties of natural fiber reinforced polymer composites. Compos Part B Eng 42(4):856–873. ISSN: 1359-8368

McDougall GJ, Morrison IM, Stewart D, Weyers JDB, Hillman JR (1993) Plant fibers: botany, chemistry and processing for industrial use. J Sci Food Agric 62:1–20; 42:856–873

Ning H (2012) Composites and their properties. Janeza Trdine 9, 51000 Rijeka, Croatia. ISBN: 978-953-51-0711-8. doi:10.5772/2816

Ramnath V, Sekar S, Sankar S, Sankaranarayanan C, Sastry TP (2012) Preparation and evaluation of bio-composites as wound dressing material. J Mater Sci Mater Med 23(12):3083–3095

Rowell RM, Han JS, Rowell JS (2000) Characterization and factors affecting fiber properties. In: Frollini E, Leao AL, Mattoso LHC (eds) Natural polymers and agro fibers composites. USP/UNESP and Embrapa, Sao Carlos, pp 115–134. ISBN: 85-86463-06-X

Sastry TP, Sehgal RK, Ramasamy T (2005) Value added eco-friendly products from tannery solid wastes. J Environ Sci Eng 47(4):250–255

Satyanarayana KG, Sukumaran K, Mukherjee PS, Pavithran C, Pillai SGK (1990) Natural fibre-polymer composites. Cem Concr Compos 12(2):117–136

Saxena M, Morchhale RK, Asokan P, Prasad BK (2008) Plant fiber industrial waste reinforced polymer composites as a potential wood substitute material. J Compos Mater 42(4):367–384

Sekar S, Mohan R, Ramasastry M, Das BN, Sastry TP (2007) Preparation and particle characterization of composite boards using chrome shavings and various binders. Leather Age 29(2):86–92

Sekar S, Mohan R, Ramasastry M, Das BN, Sastry TP (2009) Preparation and characterization of composite boards using chrome shavings and plant fibers. J Indian Leather Technol Assoc 10:765–770

Senthil R, Hemalatha T, Kumar BS, Uma TS, Das BN, Sastry TP (2014) Recycling of finished leather wastes: a novel approach. Clean Technol Environ Policy. doi:10.1007/s10098-014-0776-x

Senthil R, Inbasekaran S, Gobi N et al (2015) Utilization of finished leather wastes for the production of blended fabrics. Clean Technol Environ Policy 17:1535. doi:10.1007/s10098-014-0881-x

Suddell BC, Evans WJ (2005) Natural fiber composites in automotive applications. In: Mohanty AK, Misra M, Drzal LT (eds) Natural fibers, biopolymers and biocomposites. CRC, Boca Raton, pp 37–71

Sun J, Sun X, Zhao H, Sun R (2004) Isolation and characterization of cellulose from sugarcane bagasse. Polym Degrad Stab J 84(2):331–339

Xie Y, Hill CAS, Xiao Z, Militz H, Mai C (2010) Silane coupling agents used for natural fiber/polymer composites: a review. Compos A 41:806–819

Zulfikar A (2012) Assessment of tannery solid waste management and characterization a case of Ethio-Leather Industry Private Limited Company (ELICO). MSc thesis, Addis Ababa, Ethiopia

Acknowledgements

Leather Industry Development Institute (LIDI) and Addis Ababa University (AAU) of Ethiopia and Council for Scientific and Industrial Research-Central Leather Research Institute (CSIR-CLRI) of India are acknowledged for providing funds and every opportunity to pursue the study. Special thanks are extended to Dr. Inbasekaran S. at CLRI slaughter house pilot plant for his assistance in facilitation and collection of different plant samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Teklay, A., Gebeyehu, G., Getachew, T. et al. Preparation of value added composite boards using finished leather waste and plant fibers—a waste utilization effort in Ethiopia. Clean Techn Environ Policy 19, 1285–1296 (2017). https://doi.org/10.1007/s10098-016-1327-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1327-4