Abstract

Quercus variabilis Blume, the Chinese cork oak, is an oak species with a thick cork outer bark. The cork is exploited at a limited scale in China and considered of lower quality than the commercial cork from Quercus suber. We studied an industrial cork granulate feedstock of Q. variabilis in relation to cellular structure and chemical composition and compared it to Q. suber cork under a material’s perspective. The cork of Q.variabilis has 1.1 % ash, 9.6 % extractives, 34.8 % suberin and 19.1 % lignin. The monosaccharide composition with shows a predominance of hemicelluloses: glucose 42.8 % of total neutral sugars, xylose 27.5 %, arabinose 15.4 %, galactose 9.0 %, mannose 4.0 %, rhamnose 1.2 %. The FT-IR spectrum shows the indicative peaks of suberin. The composition is overall similar to that of Q. suber cork. Q. variabilis cork has the typical cellular characteristics of bark cork tissues with a regular and radially aligned structure of cells without intercellular voids. Solid volume fraction was estimated at approximately 16 %. Compared with Q. suber, the Q. variabilis cork cells are smaller, the cell wall undulation and the overall row alignment less homogeneous, the cell surface is irregular and the solid volume proportion higher. The characteristics of Q. variabilis cork support its use as a cellular material for sealing, insulation and energy absorption, but the overall quality is lower than that of Q. suber cork. The negative impact of the higher density and structural lower uniformity at tissue and cell level should be evaluated for processing and product performance.

Similar content being viewed by others

Introduction

Cork is a closed-cell biological material with a set of specific properties that result from its chemical composition and cellular structure, i.e. very low permeability, hydrophobic behaviour, biological inertia, large elastic compression and dimensional recovery. Cork has been extensively studied in the cork oak (Quercus suber L.), due to its economic importance for production of wine stoppers and insulation materials, and its structure, chemistry and properties have been reviewed in a reference book [1].

The basis of many of the cork physical properties lies to a large extent in the features of its cellular structure: the individual cells are small hexagonal prisms that are stacked base to base forming cell rows, with rows aligned parallel to each other in a compact and regular arrangement [1]. This type of cellular structure is common to cork tissues, but cell dimensions including cell wall thickness vary between species, leading to different solid volume ratio and material’s density [2, 3].

Chemically, cork is characterized by the presence of suberin as a major cell wall structural component. Suberin is a macromolecule of ester coupled fatty alcohols, fatty acids and diacids, hydroxy fatty acids and glycerol, including also ferulic acid and eventually other phenolic components [1, 4–7]. Suberin content varies with species, i.e. 40 % in Quercus suber [8], 29 % in Quercus cerris [9], 53 % in Pseudotsuga menziesii [10], 5 % in Calotropis procera [11], 45 % in Betula pendula [12], 48 % in Fagus sylvatica and 43 % in Castanea sativa [13, 14]. The cork cell wall further includes lignin and the polysaccharides cellulose and hemicelluloses, while polar and non-polar extractives are also present with a considerable content [8, 15–21].

The cork that is stripped from the outer bark of the cork oak (Quercus suber) is one of the most important non-wood forest products. Its production is geographically restricted to the western part of the Mediterranean, including southern European and northern African regions, with the largest production concentrated in Portugal and Spain [22]. The raw cork is processed into wine stoppers, surfacing materials, insulation boards and other products, and exported worldwide [1].

The idea of exploiting other sources of cork, e.g. cork contained in the bark of other species, that may be present in other regions of the world, is only logical. This was the underlying objective of recent studies on the cork contained in the bark of the Turkey oak (Quercus cerris) and detailed characterization of cellular structure, chemical composition and thermochemical behaviour was made [3, 9, 23–25]. The utilization of cork from the Betula pendula bark was also considered [12].

One species that contains a large quantity of cork in its bark periderm and that forms a continuous layer around the tree stem (as it is the case in Q. suber) is the oriental or Chinese cork oak Quercus variabilis Blume (family Fagaceae, genus Quercus, section cerris) that grows in China, Korea and Japan. In China it is found mostly in the Saanchxi province and in neighbouring western Hubei and eastern Sichuan provinces, growing in mixed or in some cases pure forests, especially in the Dabie mountains, and also in the Qinling and Taihang mountains. It is a deciduous medium-to-large sized tree (20–30 m) with an open crown.

It is cultivated and already exploited in China at a limited scale for the production of cork, but quality of the raw material and of the subsequent products is considered inferior to the well established cork products from Q. suber. Some works on the characterization of Q. variabilis cork can be found i.e. on structure and chemical composition, with cork of Q. suber always as a reference [26–29].

In this study we analysed the cork of Quercus variabilis as a commercial granulate from China from a material’s point of view, and taking into account our expertise in Q. suber cork characterization and processing [1]. It is the aim to enlarge the knowledge on the characteristics of cork tissues of different species, and specifically to study the features of Q. variabilis cork that may lead to intensification of its use in complementarity to the present commercial Q. suber cork.

Materials and methods

Cork samples from Quercus variabilis Blume were obtained from a commercial industrial granulate feedstock from China. The cork granules were fractionated into different sieve fractions, and the 1–2 mm and >2 mm fractions (that corresponded to 79.3 and 8.2 % of the material, respectively) were kept for analysis.

Cellular structure observations

The cork granules were cut with a sharp razor blade in order to have clear observation surfaces. The granules were mounted on stubs (ProSciTech, Australia) and sputter coated (Polaron E 5100 E, USA) with gold palladium for 3 min at 20 mA. The surfaces were observed in an electron scanning microscope Hitachi S-2400 at magnifications ranging from 50 to 1000X, and the images were recorded in digital format. The images had the dimensions of 1000 × 750 pixels (1 pixel = 8 bits), and the time of image acquisition for each pixel was 50 μs.

The cell measurements were made on the images corresponding to tangential and non-tangential (transverse and radial) sections using image analysis software (Leica Qwin Plus). The measurements were made only on sections that represented tangential (the honeycomb type cellular arrangement) and non-tangential (the brick wall type of structure) orientations, as checked by the perpendicular sectioning of the cells [1]. All other images were discarded for measurement purposes and used only for descriptive observation of other features.

The number of edges of each cell was counted on the tangential and non-tangential sections. The distribution function of the number of edges of each cell was calculated based on the results of a total of 1000 cells for each the tangential and the non-tangential (radial and transverse) sections as f i = N i /ΣN i where N i represents the number of cells with i edges and ΣN i the total number of cells. This is a measure of the frequency of cells with a certain number of edges and consequently Σf i = 1. The dispersion of the function in relation to the mean (i m) was calculated as μ 2 = Σ(i − i m) [2] f i . This variable measures the topological disorder of a bidimensional network and may vary between 0 and ∞. The maximum order, for instance if all the cells had 6 edges, would be as μ 2 = 0.

The average cell area was calculated on the tangential sections based on the image area and the number of cells, corresponding to the average prism base area. On the non-tangential sections the following measurements were made: radial dimensions of each cell (corresponding to the cell prism height), and of the lumen. On the tangential sections, the cell widths were measured in two perpendicular directions of each cell and of the lumen. The cell wall thickness was calculated based on these two measurements as (cell dimension − lumen dimension)/2. A total of 500 cells were measured for each section.

The cork volume occupied by the solid walls was calculated by taking the individual cell as a hexagonal prism, and the solid volume (V s) as the difference between total volume (V) and the empty (lumen) volume (V o), as given by

with l as the prism base edge, h the prism height and e the total wall thickness (between two cells). Figure 1 schematically depicts one cell as a hexagonal prism, showing the prism base edge (l), the prism height (h) as well as the radial and axial directions.

Chemical analyses

The cork granulate was ground in a Retsch SK hammer mill, sieved and the 40–60 mesh fraction was kept for chemical analysis.

Chemical summative analyses included determination of ash, extractives soluble in dichloromethane, ethanol and water, suberin, klason and acid soluble lignin, and the monomeric composition of polysaccharides. The unextracted original cork was also used to determine 1 % NaOH solubles.

Ash content was determined according to TAPPI Standard T 15 os-58 using 2.0 g of material that were incinerated at 450–500 °C overnight and the residues weighed.

The alkaline lixiviation with 1 % NaOH was carried out in a stirred glass reactor with reflux using 1.0 g of material with a 1:50 solid:liquid ratio, at 100 °C and 1 h contact time.

The extraction with organic solvents and water was performed in a Soxtec extractor during 1.5 h with each solvent, successively with dichloromethane, methanol, ethanol and water; the solvents were recovered and the extractives content determined from the mass of the solid residue after drying at 105 °C, and reported as a percentage of the original samples.

Suberin content was determined in the extractive-free material by use of methanolysis for depolymerisation [8]. A 1.5 g sample of extractive-free material was refluxed with 100 ml of a 3 % methanolic solution of NaOCH3 in CH3OH during 3 h. The sample was filtrated and washed with methanol. The filtrate and the residue were refluxed with 100 ml CH3OH for 15 min and filtrated again. The combined filtrates were acidified to pH 6 with 2 M H2SO4 and evaporated to dryness. The residues were suspended in 50 ml water and the alcoholysis products recovered with dichloromethane in three successive extractions, each with 50 ml dichloromethane. The combined extracts were dried over anhydrous Na2SO4, and the solvent was evaporated to dryness. The suberin extracts, that include the fatty acid and fatty alcohol monomers of suberin, were quantified gravimetrically, and the results expressed in percent of the initial dry mass.

Klason and acid-soluble lignin, and carbohydrates contents were determined on the extracted and desuberinised materials. Sulphuric acid (72 %, 3.0 ml) was added to 0.35 g of the material sample and the mixture was placed in a water bath at 30 °C for 1 h, after which the sample was diluted to a concentration of 3 % H2SO4 and hydrolysed for 1 h at 120 °C. The sample was vacuum-filtered through a crucible and washed with boiling purified water. Klason lignin was determined as the mass of the solid residue after drying at 105 °C. The acid-soluble lignin was determined on the combined filtrate by measuring the absorbance at 206 nm using a UV/VIS spectrophotometer.

The polysaccharides were calculated based on the amount of the neutral sugar monomers released by total hydrolysis, after derivatisation as alditol acetates and separation by gas chromatography with a method adapted from Tappi 249 cm-00. The hydrolysed carbohydrates were derivatized as alditol acetates and separated by GC (HP 7820A gas chromatograph) equipped with a FID detector, using helium as carrier gas (1 ml/min) and a fused silica capillary column BPX70 (30 m × 0.32 mm, i.d. × 0.20 μm film thickness). The column program temperature was 225–250 °C, with 5 °C/min heating gradient, and the temperature of injector and detector was 250 °C. For quantitative analysis the GC was calibrated with pure reference compounds and inositol was used as an internal standard in each run.

FT-IR spectroscopy

Aliquots of 500 mg of the cork sample were ground with a Retsch MM200 mixer mill for 20 min. After grinding the samples were dried at 105 °C for 24 h before pellet preparation.

Samples with 2.3 ± 0.1 mg were mixed with 250 ± 2 mg KBr, ground with the Retsch MM200 mill for 2 min and dried for 24 h in vacuum over anhydrous P2O5. An amount of 150 ± 1 mg of the mixture was used for preparing KBr pellets. The resulting pellets were analysed in absorption mode FT-IR in the 500–4000 cm−1 range with a resolution of 4 cm−1 and 64 scans accumulation. All spectra were normalised for the highest band in the 500–4000 cm−1 range.

Results

Cellular structure

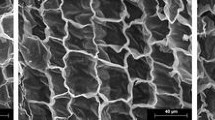

The structure of the cork of Q. variabilis as observed by scanning electron microscopy in the tangential and non-tangential sections is shown in Fig. 2. The cells were structurally arranged without intercellular voids and formed in each section a bidimensional network of edges and vertices.

The general appearance differed between the tangential and the non-tangential sections. The cork cells showed a honeycomb-type structure in the tangential section (Fig. 2a) and a brick wall-type in the non-tangential sections with an alignment in parallel rows (Fig. 2b, c).

The cells were polygonal but the topological description of the tangential and non-tangential sections showed differences in relation to the number of sides of each cell (Table 1). In the tangential section, 60 % of the cells had six sides, with five- and seven-sided polygons making up most of the other cases. The dispersion around the average of the number of polygonal edges was low, reflecting a large homogeneity of cell shape. In the non-tangential section, the highest proportion of the cells had five sides but very close to the proportion of cells with six sides, with the remaining cells having four sides. Therefore, in the majority of cases three cells meet at each vertex of the network in the tangential surface, while in the non-tangential surface in many cases four cells meet at each vertex.

The cork showed a layered structure with variation of cell size, i.e. cork rings: the cells formed in the main growth period (earlycork cells) were larger and had thinner walls and at the end of the growth period the cells (latecork cells) had thicker walls and a much smaller dimension in the radial direction (Fig. 3). In each ring, only 2–4 latecork cells were found.

The cell dimensions are summarized in Tables 2 and 3. On average, in earlycork cells the prism height (radial width) was 21 μm, the prism base area was 764 μm [2] corresponding to a base edge of 17 μm and the cell wall thickness 1 μm; in latecork the prism height was reduced to 10 μm, and the cell wall thickness increased to about 3 μm. However, the cork dimensions were far from uniform, and there were very large variations within each cork granule and between granules: for instance, in early cork the prism height was found to vary in individual cells from 7 to 69 μm and the wall thickness from 0.7 to 1.5 μm. The aspect ratio of the cells (h/l) was about 1.1 in earlycork cells.

The three-dimensional structure of cork was compact and may be described as being formed by hexagonal prisms that are stacked base-to-base forming rows oriented in the radial direction and assembled side by side. The mean prism dimensions are summarized in Table 3. The prism height of each cell is oriented in the radial direction and the prism base lies in a tangential plane. In adjacent rows the prism bases of neighbor cells are either coincident in some of the cases or most often lay in staggered positions.

The cork volume occupied by the solid may be calculated using the average dimensions of the cellular units. The solid fraction in the cork calculated in percent volume is approximately 13 % in the earlycork and 40 % in the latecork region (Table 3). If latecork would represent about 10 % of the total, the overall solid fraction would be about 16 %.

The solid distribution in faces and edges was rather uniform and the cell edges had substantially the same cell wall thickness as faces, apart from a slight rounding observed at the inner side of cells at face junction (Fig. 4). In many cases the cell surface was not smooth and appeared granulated, and the cells contained plenty of deposits (Fig. 4). Remnants of fungal hyphae were also observed (Fig. 5). In a few cases circular openings with a diameter of about 0.3 μm were found in the cell surface connecting two cells (Fig. 6).

The cell faces that were oriented along the radial direction i.e. the prism lateral faces, had in most cases cell wall undulations (Fig. 7). The pattern of undulations was not uniform and one, two or three corrugations per face could be seen. In some regions, especially the earlycork cells that were formed against the previous latecork cells, showed heavy corrugations and compression in the radial direction that could lead to cell row distortion (Fig. 2c). The cell prism bases did not show undulations, although some buckling might occur.

Figure 8 shows for comparative purposes one scanning electron micrograph of the transverse section of cork from Quercus suber where the boundary between one annual ring can be observed.

Chemical composition

The summative chemical composition of cork from Quercus variabilis is shown in Table 4, along with the chemical composition of cork from Q. suber for comparison. Extractives amounted to 9.6 % of the cork mainly corresponding to non-polar compounds that were soluble in dichloromethane (51 % of the total extractives). The cork of Q. variabilis contained a considerable amount of suberin (39.2 % of the material) and a lignin content of 22.2 %. The alkaline treatment of cork with 1 % NaOH solubilised 53.3 % of the material.

The carbohydrate composition is summarised in Table 5 as regards proportion of neutral monosaccharides. Glucose amounts to 43 % and the pentoses, xylose and arabinose, show considerable amounts (28 and 15 %, respectively).

FT-IR spectra

Figure 9 shows the FT-IR spectrum of the cork granulates of Q. variabilis. The spectrum has the features of a cork material with sharp intense bands at 2923, 2852, 1739, 1264 and 1160 cm−1, characteristic of C–H and O–C=O vibrations in aliphatic fatty esters, a medium band at 1512 cm−1 characteristic of G-lignin aromatic ring vibrations and medium 3425 and 1035 cm−1 bands from carbohydrates and lignin O–H and C–O vibrations [20, 30, 31].

Discussion

The results of this paper bring an integrated description of Q. variabilis cork cell structure and chemical composition that allows a comparison with the known features of the commercial valuable Q. suber cork.

Overall the cellular structure of Q. variabilis cork is similar to that found in corks of other species, namely in Q. suber [1, 2] and Q. cerris [3] with a regular and compact arrangement of small closed cells that results from its biological formation process [32]. Some differences are however present, as discussed in sequence.

The topology of Q. variabilis cork as regards the distribution of the number of cells in each section (Table 1) showed a higher dispersion in the non-tangential sections and differs from Q. suber cork where the three sections are topologically very similar with 6-sided cells representing a fraction of 0.48 and 0.53 in tangential and non-tangential sections, respectively [2]. It resembles however the cork of Q. cerris that also had a significant proportion of five sided cells in the non-tangential section [3]. Another difference of Q. variabilis cork lies in a more heterogeneous undulation of the cell walls (Figs. 2c, 7) and of a more irregular row alignment in comparison to Q. suber. Figure 9 shows a SEM micrograph of a transverse section of cork from Q. suber for comparison where the regular radial alignment of the cell rows can be observed.

The cell dimensions of Q. variabilis cork (Tables 2, 3) are smaller than those of Q. suber in relation to the prism height in the earlycork cells (21 μm vs. 30–40 μm), while maintaining cell wall thickness (1 μm vs. 1–1.5 μm). The fraction of solid material in Q. variabilis cork (13 % in earlycork, Table 3) is higher compared with the 10 % of Q. suber cork [1] due to the smaller cell dimensions. In consequence Q. variabilis cork will have a higher density and therefore somewhat loose the competitive advantage of the very low density of Q. suber cork and other cellular materials used for insulation. A similar feature regarding cell dimensions and solid volume fraction was also obtained for the cork in Q. cerris bark [3].

The structural characteristics that we described for Q. variabilis cork match in general the reported values by [29]. Some aspects should however be stressed. We found fungal development in many cells and the openings found on the surface of some cells (Fig. 6) should be in our opinion channels opened by fungal growth. Remnants of fungal hyphae could be observed in the samples as shown on Fig. 5. It has been shown that filamentous fungus grow on Q. suber cork e.g. Chrysonilia sitophila, Penicillium spp, Trichoderma spp, and penetrate through the cell wall by hyphal perforation [33].

Also a striking difference between the cork cells of Q. variabilis and of Q. suber refers to the appearance of the cell wall: while in Q. suber the lumen side of the cork surface is smooth and shows deposits only occasionally, in Q. variabilis the cell surface is rough with deposits of various sizes (Figs. 4, 5).

The chemical composition of Q. variabilis cork is within the general range reported for cork of Q. suber, but with some differences. The content of extractives is lower than the 14–17 % reported for Q. suber and with a higher proportion of non-polar compounds extracted by dichloromethane (in Q. suber they represent 42 % of total extractives) [8].

The suberin content is well within the range found for Q. suber cork (23–49 %) [1] as well as lignin content (21–23 %) reported for Q. suber cork [8]. The carbohydrate composition shows a predominance of xylan-based hemicelluloses (glucose amounts to 43 % of the neutral sugars, Table 5) that is similar to the results found for Q. suber and Q. cerris corks [1, 9]. Ash content is similar to the value reported for Q. suber cork (1 %) [8]. Overall the chemical composition of Q. variabilis resembles more that of Q. cerris cork [9].

The FT-IR spectral features of Q. variabilis cork (Fig. 9) showed the typical peak characteristics of a suberin-containing material, namely the peaks at 2923 and 2852 cm−1, corresponding to the CH2 stretch absorption, and the sharp peak at 1739 cm−1 of the ester bonds present in suberin. Overall the spectrum was similar with those of corks of Q. suber, Pseudotsuga meziesii and Q. cerris [20, 24, 30].

The combined characteristics of Q. variabilis cork cells structure and composition will influence the material’s properties, its behaviour during processing and performance in use, as detailed for Q. suber cork [1]. Overall the quality of Q. variabilis cork may be estimated as lower than that of Q. suber in what relates to density and to the mechanical properties associated to elasticity. The response of Q. variabilis cork to processing operations such as water boiling [34] that could help to a higher cellular structural uniformity should be assessed as well as a screening on the incidence and extent of microbial development on the cork cells. However the structural and chemical features of Q. variabilis cork show their potential for the traditional usages of cork as a complementary raw-material to Q. suber cork in less demanding products.

Conclusions

The cork of Quercus variabilis shows typical structural and chemical features of bark cork tissues with a regular structure of radially aligned suberised cells without intercellular voids. These characteristics support its use as a cellular material namely for sealing, insulation and energy absorption. However, and taking as reference the cork from Q. suber, the cells of Q. variabilis are smaller, the solid volume fraction is higher, the structure more heterogeneous at tissue and cell level, and the overall quality lower. The negative impact of these characteristics should be evaluated for processing and product performance.

References

Pereira H (2007) Cork: biology, production and uses. Elsevier Publications, Amsterdam

Pereira H, Rosa ME, Fortes MA (1987) The cellular structure of cork from Quercus suber L. IAWA Bull 8(3):213–218

Şen A, Quilhó T, Pereira H (2011) The cellular structure of cork from Quercus cerris var. cerris bark in a materials’ perspective. Ind Crop Prod 34(1):929–936

Bento MF, Pereira H, Cunha MA, Moutinho AMC, Van den Berg KJ, Boon JJ (2001) A study of variability of suberin composition in cork from Quercus suber L. using thermally assisted transmethylation GC-MS. J Anal Appl Pyrol 57(1): 45–55

Graça J, Pereira H (2000) Diglycerol alkanedioates in suberin: building units of a poly(acylglycerol) polyester. Biomacromolecules 1(4):519–522

Graça J, Pereira H (1998) Feruloyl esters of ω-hidroxyacids in cork suberin. J Wood Chem Tech 18(2):207–217

Graça J, Pereira H (1997) Cork suberin: a glyceryl based polyester. Holzforschung 51(3):225–234

Pereira H (1988) Chemical composition and variability of cork form Quercus suber L. Wood Sci Technol 22(3):211–218

Şen A, Miranda I, Santos S, Graça J, Pereira H (2010) The chemical composition of cork and phloem in the rhytidome of Quercus cerris bark. Ind Crop Prod 31:417–422

Graça J, Pereira H (1999) Glyceryl-acyl and aryl-acyl dimers in Pseudotsuga menziesii bark suberin. Holzforschung 53(4):397–402

Pereira H (1988b) Structure and chemical composition of cork from Calotropis procera (Ait.) R. Br. IAWA Bull 9(1):53–58

Pinto PCRO, Sousa A, Silvestre AJD, Neto CP, Gandini A, Eckerman C, Holmbom B (2009) Quercus suber and Betula pendula outer barks as renewable sources of oleochemicals: a comparative study. Ind Crops Prod 29:126–132

Holloway P (1983) Some variation in the composition of suberin from cork layers of higher plants. Phytochem 22:495–502

Gandini A, Neto CP, Silvestre AJD (2006) Suberin: a promising renewable resource for novel macromolecular materials. Prog Polym Sci 31:878–892

Conde E, García-Vallejo MC, Cadahía E (1999) Waxes composition of Quercus suber reproduction cork from different Spanish provenances. Wood Sci Technol 33:270–283

Conde E, Cadahía E, García-Vallejo MC, de Simon BF, Adrados JRG (1997) Low molecular weight polyphenols in cork of Quercus suber. J Agric Food Chem 45:2695–2700

Castola V, Bigelli A, Rezzi S, Melloni J, Gladiali S, Desjobert JM, Casanova J (2005) Composition and chemical variability of the triterpene fraction of dichloromethane extracts of cork (Quercus suber L.). Ind Crops Prod 21:65–69

Castola V, Marongiu B, Bigelli A, Floris C, Lai A, Casanova J (2002) Extractives of cork (Quercus suber L.): chemical composition of dichloromethane and supercritical CO2 extracts. Ind Crops Prod 15:15–22

Marques AV, Pereira H, Meier D, Faix O (1999) Structural characterization of cork lignin by thioacidolysis and permaganate oxidation. Holzforschung 53(2):167–174

Marques AV, Pereira H, Meier D, Faix O (1996) Isolation and characterization of a guaiacyl lignin from saponified cork of Quercus suber L. Holzforschung 50(5):393–400

Marques AV, Pereira H, Meier D, Faix O (1994) Quantitative analysis of cork (Quercus suber L.) and milled cork lignin by FTIR spectroscopy, analytical pyrolysis and total hydrolysis. Holzforschung 48 (suppl.): 43–50

Pereira H, Tomé M (2004) Cork oak. In: Burley J (ed) Encyclopedia of forest sciences. Oxford Elsevier Ltd., Oxford, pp 613–620

Şen A, Miranda I, Pereira H (2012) Temperature-induced structural and chemical changes in cork from Quercus cerris. Ind Crop Prod 37:508–513

Şen A, Velez Marquez A, Gominho J, Pereira H (2012) Study of thermochemical treatments of cork in the 150–400 °C range using colour analysis and FTIR spectroscopy. Ind Crop Prod 38:132–138

Şen A, Quilhó T, Pereira H (2011) Bark anatomy of Quercus cerris L. var. cerris from Turkey. Turk J Bot 35:45–55

Zhang L (2009) Contents of the main chemical components of cork from Quercus variabilis. J North-Western For Univ 24:163–165

Wei X (2007) Chemichal composition and its effect on properties of cork from three geographical locations. Chin Wood Ind 6:17–18

Lei Y, Jia T, Song X (2012) Chemical composition of cork from Quercus variabilis. Wood Fiber Sci 44(2):1–6

Lei Y, Liu Y, Zhou W, Zhao Y (2009) The microstructure of cork from Quercus variabilis. Sciencia Silvae Sinicae 45(1):167–170

Marques AV, Pereira H, Rodrigues J, Meier D, Faix O (2006) Isolation and comparative characterization of Björkman lignin from the saponified cork of Douglas fir Bark. J Anal Appl Pyrol 77:169–176

Faix O (1991) Classification of lignins from different botanical origins by FTIR spectroscopy. Holzforschung 45:21–27

Graça J, Pereira H (2004) The periderm development in Quercus suber. IAWA J 25(3):325–335

Pereira CS, Soares GAM, Oliveira AC, Rosa ME, Pereira H, Moreno N, San Romao MV (2006) Effect of fungal colonization on mechanical performance of cork. Int Biodeter Biodegr 57(4):244–250

Rosa ME, Pereira H, Fortes MA (1990) Effects of hot water treatment on the structure and properties of cork. Wood Fiber Sci 2282:149–164

Acknowledgments

The work was carried out with the base funding to Centro de Estudos Florestais given by Fundação para a Ciência e Tecnologia, Portugal, under the PEstOE/AGR/UI0239/2011 programme. We thank Inês Mirra and Joaquina Martins for their help with laboratorial analysis, and Professor António Velez Marques for FTIR analysis.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Miranda, I., Gominho, J. & Pereira, H. Cellular structure and chemical composition of cork from the Chinese cork oak (Quercus variabilis). J Wood Sci 59, 1–9 (2013). https://doi.org/10.1007/s10086-012-1300-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-012-1300-8