Abstract

Expansion of the rural road network in Ethiopia requires the availability of low-cost materials for road construction, including capping layer and subgrade improvement, sub-base, base course, gravel wearing course and bituminised surface treatment. A reluctance to use cinder gravels for these purposes in the past has stemmed from the view that their properties, in terms of grading and CBR strength, are marginal and highly variable when compared to international specifications for road works. The geographical variability in Ethiopian cinder gravel geochemistry and engineering properties is described and comparisons are made with engineering geological field descriptions and cinder cone morphology, leading to the conclusion that maars and steep-sided, well-defined cones tend to yield the better-quality materials. The performance of trial sections of road constructed using cinder gravel is assessed and combined with the results of laboratory testing to develop a guideline for the wider use of the material in roadworks, either directly or through processes of blending, alternative compaction methods and cement stabilisation to yield a product that can be considered “fit for purpose” for a range of uses in low-volume road construction.

Similar content being viewed by others

Introduction

Ethiopia has one of the lowest road densities and lowest Rural Accessibility Indexes in Sub-Saharan Africa (World Bank 2016). The second Growth and Transportation Plan of the country involves the construction of 100,000 km of road between 2015 and 2020, and it is likely that this planned expansion of the road network will continue in later years and decades. The geological outcrop pattern of Ethiopia is as complex as any country, with a wide range of igneous, metamorphic and sedimentary rocks. A humid, sub-tropical climate has led to the development of deep residual soils in many parts of the country, with large areas containing very limited naturally occurring gravels for use in road construction. The haulage of suitable naturally occurring gravels over long distances, and the use of crushed rock as road construction aggregate, are expensive operations that limit the effectiveness of resource-constrained road construction and rehabilitation programmes.

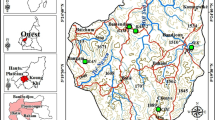

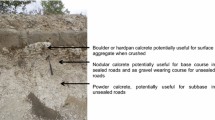

The Rift Valley is the most active divergent intra-continental plate boundary in the world. During the Plio-Pleistocene, felsic and mafic lavas and pyroclastic materials have been extruded and ejected from fissures and vents bordering the Rift Valley and the Afar Depression, with Holocene activity continuing on the Rift Valley floor in association with the active Wonji Fault Belt (Fig. 1). Pyroclastic material ejected during these events has typically formed cones comprising ash, lapilli, bombs and blocks of varying vesicularity. Basaltic scoriaceous (cinder) gravel, cobbles and boulders are common constituents of these cones and, in some areas, have been extensively quarried for use in the manufacture of hollow blocks. Selected materials have also been used as subgrade replacement, capping layer and sub-base in trial sections of road construction and as surfacing gravel in the rehabilitation of some town roads.

Cinder gravel offers significant potential as a low-cost, naturally occurring material in low-volume rural road construction and rehabilitation. However, the variability in its engineering parameters, particularly its grading, density, porosity and strength, have meant that the material often fails to meet standard specifications for road construction. This paper describes a study carried out under the Africa Community Access Partnership (AfCAP) to develop a guideline for the greater use of cinder gravel in the road sector of Ethiopia.

Origin and composition of scoria (cinder gravel)

The geochemical properties of magma vary according to differences in source mineralogy and gas content, conditions of ascent towards the Earth’s surface and the degree to which other “country” rocks are incorporated during its ascent. As magma ascends, its confining pressure decreases and its temperature drops, and important changes to its composition take place. Dissolved gases begin to come out of solution and crystallisation occurs. These processes determine the geochemistry and rheology of the lava and pyroclastic materials that are ultimately extruded and ejected. Magma viscosity depends on temperature and silica (SiO2) content. Felsic magmas (rich in silicate minerals) tend to be the more viscous, with higher retained gases, resulting in explosive Plinian-type eruptions and the production of low-density pumice-like lapilli and rhyolitic and andesitic lavas. Mafic magmas (rich in ferromagnesian minerals) are less viscous, facilitating some degassing of the magma prior to its eruption. Basaltic lava flows and Strombolian-type eruptions, yielding higher density lapilli, are common.

The larger volcanoes tend to be formed from silica-dominated materials, whereas small-volume volcanoes are usually composed of alkaline-rich and silica-undersaturated materials (Smith and Németh 2017). Basaltic lapilli are generated by magma fragmentation during these relatively small to moderate explosive eruptions forming cinder cones around a central volcanic vent. Small (usually much less than 1km3 in volume) cinder cones are often monogenetic (e.g. Anon 2011; Smith and Németh 2017), i.e. they form during a single volcanic event, though these events can be multi-phased and can extend over periods of a few days to a number of years (Walker 1993). The geometry or morphometry of cinder cones has been studied by several authors (e.g. Settle 1979; Wood 1980a, b; Valentine et al. 2007; Bemis et al. 2011; Inbar et al. 2011; Fornaciai et al. 2012; Dóniz-Páez 2015; Uslular et al. 2015; Bemis and Ferencz 2017). However, few authors have described the composition of cinder cones in relation to their morphometry, presumably due to lack of exposure. Those that have, for example Valentine et al. (2007) and Kereszturi and Németh (2016), describe high variability in stratigraphic and granulometric properties.

Phases of gaseous explosion result in pulses of eruption and eruptive intensity, with the deposition of tephra of varying sizes, often leading to a distinct layering of cinder gravel and ash (Houghton and Carey 2015). Where mafic magma mixes with large quantities of groundwater or surface water, eruptions tend to be more explosive, creating maars, rather than cones, with low amplitude relief and large-diameter craters. The lapilli that form maar deposits tend to be aphyric (fine-grained) due to the quenching effect of water on pre-crystallised magma. Quenching tends to inhibit vesiculation and encourages thermal fracturing (Sparks et al. 1997). Maar deposits also contain large quantities of fragmented country rock (lithic fragments), ripped from the conduit walls during explosive eruptions.

Although monogenetic cinder cones are commonly formed by a discrete body of magma that rises rapidly to the Earth’s surface, the geochemistry of the erupted pyroclasts can vary significantly within individual cones (Smith and Németh 2017). These authors observe that geochemical composition is often correlated with cone deposit stratigraphy.

Cinder gravels in Ethiopia

Geology

The opening of the Main Ethiopian Rift (MER, Fig. 1) commenced in the early-mid Miocene. The southern and central MER became dominated by silicic volcanic eruptions, giving rise to the creation of large-diameter calderas, such as at Hawassa (see Fig. 1) and extensive deposits of ash and pumice. The pumice is aphyric, with only minor phenocrysts in a glassy vesicular groundmass (Barberio et al. 1999). As rifting continued, eruptions of basaltic and silicic volcanic materials took place along the rift margins, depositing large quantities of lava and pyroclastic materials on the floor of the MER. The basaltic products of these eruptions tend to be microcrystalline-porphyritic in structure, with phenocrysts of plagioclase, clinopyroxene and olivine (Barberio et al. 1999; Chernet and Hart 1999). The tectonic and volcanic development of the MER is described extensively in the published literature (e.g. Barberio et al. 1999; Boccaletti et al. 1999a, b; Chernet and Hart 1999; WoldeGabriel et al. 1999; Abebe et al. 2007; Rooney et al. 2011).

Basaltic cinder cones (Fig. 2) and maars (Fig. 3) tend to occur in clusters that are aligned along the margins of the MER and are Plio-Pleistocene in age, and within the Wonji Fault Belt on the floor of the Rift Valley (Fig. 1) that are Holocene in age. Other cinder cone clusters occur along the western rift margin of the Afar Depression, along the Yerer-Tullu Wellel volcano-tectonic lineament (Fig. 1) - a proto-MER (e.g. Abebe et al. 1998; Meshesha and Shinjo 2007; Adhana 2014), and in the Bahir Dar-Injibara area of the Tana Graben/Rift (e.g. Berhe et al. 1987; Chorowicz et al. 1998; Ayalew et al. 2003; Meshesha and Shinjo 2007). Rooney et al. (2011) suggest that the Plio-Pleistocene volcanism, and resulting NE-SW aligned cinder cones of the western MER between Silte, Butajira and Bishoftu (Fig. 1), can be considered as one volcano-tectonic zone while the volcanism on the eastern side of the MER can be regarded as belonging to the Wonj Fault Belt. These authors consider the magma geochemistry of the western zone to be indicative of high-pressure crystal fractionation at depth and the possible incorporation of mafic crustal materials, contrasting with inferred shallower magma emplacement and fractionation beneath the Wonji Fault Belt. Cinder cones within the Wonji Fault Belt largely developed as secondary eruptions on the northern and southern rims of major felsic calderas (Abebe et al. 2007). These differences may have implications for variations in the mineralogy, vesicularity and strength of the resultant cinder gravels in each area.

Engineering use

Cinder gravel has been used in a number of engineering applications in Ethiopia. Among the first to be documented was its use as sub-base and base course in low-volume roadsFootnote 1 by Newill et al. (1979), Newill and Aklilu (1980) and Newill et al. (1987). These studies involved sampling, laboratory testing, field compaction trials and ultimately full-scale application trials. The general conclusion was that cinder gravels blended with volcanic ash or quarry fines can be used as sub-base and base course on sealed roads with up to 440,000 ESAs and a pavement design based on Overseas Road Note 31 (TRL 1993). Observations by the present authors have confirmed that these trial sections of road continue to perform satisfactorily with increased traffic loads, of up to three million ESAs. Other investigations have examined the suitability of cinder gravel as base course material when blended with fine-grained soils and volcanic ash and with lime stabilisation (e.g. Ayele et al. 2002; Berhanu 2009; Eshete 2011; Hadera 2015). Despite the success of these various investigations, the wider use of cinder gravel as a road construction material in Ethiopia has been constrained due to a lack of material specification and clear guidelines on prospecting, sampling, preparation and application. The current use of cinder gravel is dominated by the hollow block construction industry and many cinder cones and related landforms have been exploited for this purpose.

The AfCAP study

The principle objectives were to:

-

Describe the various cinder deposits observed in terms of their morphology, stratigraphy, size distributions and apparent strength;

-

Implement a cinder material sampling programme for laboratory testing, including geochemical testing;

-

Compare the field descriptions with the laboratory test results;

-

Compare the geographical distribution and morphology of the cinder cones with the field descriptions and laboratory-determined strength values;

-

Examine the performance of road pavements already constructed using cinder gravel;

-

Develop a guideline for future practice in the investigation, design and construction of low-volume road pavements using cinder gravel.

Excavation plant was unavailable to the study and, in any case, the necessary licenses were not in place to carry out intrusive investigations. Therefore, sampling from cinder cones had to be undertaken where materials had already been exposed in excavations by contractors, predominantly for use in hollow block construction. Google Earth® was used to identify cinder cones containing borrow pits, and a campaign of field investigations was implemented in the cinder cone clusters shown in Fig. 1. A total of 56 locations were selected, and at each an assessment was made of the bedding, size-range and strength-range of the material prior to sampling.

Field descriptions

One of the most striking observations made during the field investigations was the extremely high variability of materials exposed in the excavation faces (Fig. 4). This variability was most marked in the layering of finer and coarser pyroclastic materials, with well-defined beds of coarse gravels and cobbles, for example, being interlayered with finer materials, including ash and pea-sized cinder. Some cinder gravel layers were relatively “clean” in that they contained very little fine-grained material, while others formed a clast-dominated deposit with a matrix of sand-sized “grit”. In some cones the layering of individual beds was far less distinct, resulting in an incoherent mixture of cobbles, gravels and gritty matrix with occasional boulders.

There was also significant variability in the colour, angularity, vesicularity, and apparent strength of the materials. For example, layers of dark grey-black cinder were interlayered with red-brown oxidised material and different parts of some borrow pits were found to be predominantly one colour or the other. Vesicularity also varied significantly between deposits within the same cone, as did the apparent strength of individual clasts. However, the greatest differences were found to occur between cones, including those in close proximity. Unconfined compressive strength was assessed in the field using a geological hammer and the guidance contained in BS5930. Highly vesicular material was generally the weakest, although strength varied considerably between beds and sometimes between individual clasts within beds. Materials judged to be weak to very weak could often be found within metres of material considered to be strong. In most cases, therefore, it was not possible to assign a strength class or even a narrow strength range as being representative of the cone as a whole.

In almost all cases, the apparent dip angle of the tephra bedding controlled the slope angle of the cone. Nevertheless, there were exceptions, where post-depositional erosion had removed large parts of the original morphology. Frequently, the tephra bedding was seen to extend below adjacent ground level, by up to 30 m in some cases, demonstrating post-cone deposition of ash and other fine-grained volcanic products around the periphery of the cone.

Sampling

Large sample volumes were required to satisfy the programme of laboratory testing (see below) necessitating the collection of three 30 kg bags of each material type. At locations within close proximity to the soils laboratory in Addis Ababa it was possible to collect up to three samples (nine bags) from each borrow pit. Sampling became more constrained, however, with distance from Addis Ababa so that, in many cases, only one or two three-bag samples could be taken from each location. The high variability in observed material properties, therefore, presented significant problems for representative sampling. Instead of attempting to capture the range of materials exposed, samples were generally taken of the stronger materials (i.e. those most likely to be suitable for use in road construction). Given the large variation in materials between borrow areas, this strategy effectively meant that a range of material strengths was captured in the sampling process, allowing the suitability of the cinder gravel as a whole to be tested for a number of applications, ranging from its use as subgrade replacement, sub-base, basecourse and surfacing aggregate.

Engineering laboratory testing

The following tests were carried out on recovered samples:

-

Bulk specific gravity and water absorption (ASTM C127)

-

Particle size distribution (AASHTO T11 and T27)

-

Atterberg Limits (AASHTO T89 and T90)

-

CBR (AASHTO T193, but using a 4.5 kg rammer - T180-D)

-

Dry density (AASHTO T180-D)

-

Particle strength – Aggregate Impact Value (AIV) (BS 812–112:1990)

-

10% FACT (Fines Aggregate Crushing Test, BS 812–111:1990).

Other appropriate tests, such as uniaxial compression, point load and aggregate soundness, could not be undertaken due to lack of facilities in the Addis Ababa soils laboratory.

The average bulk dry specific gravity of the sampled cinder gravel was 1.7 g/cm3 with a range of 1.17 to 2.33 g/cm3. Interestingly, the extremes of this density range were for samples taken from borrow pits in the same cluster (Bishoftu), illustrating the range that can occur within the same cone field. The average water absorption was 12.55%, with a lower limit of 4.8% and an upper limit of 32.9%. The extremes of this range were obtained from the same two Bishoftu samples, with the highest bulk density associated with the lowest water absorption and vice versa. Figure 5 shows the relationship obtained between bulk dry specific gravity and water absorption.

Figure 6 shows the cinder gravel grading curves compared with the specification limits for sub-base materials recommended in the Ethiopia Low Volume Roads Design Manual (ERA 2017). The cinder gravels sampled are generally coarse and lacking in finer particles (less than 4.75 mm). Larger particles breakdown to smaller particles under laboratory compaction, thus contributing to the fines content (Fig. 7), allowing the cinder gravel to meet the specification for sub-base. The same applies to the use of cinder gravel as base material, as illustrated in Fig. 8.

Range of cinder gravel grading curves, prior to laboratory compaction, compared with the recommended range for sub-base in ERA (2017)

Range of cinder gravel grading curves, after laboratory compaction, compared with the recommended range for sub-base in ERA (2017)

Grading curves for compacted cinder gravels, compared with the recommended range for base course material in ERA (2017)

By definition, all cinder gravel is non-plastic, though weathered horizons, normally within 1–2 m of the cone surface, can sometimes contain plastic fines. Samples of unweathered and weathered materials from two locations were found to have Plasticity Indices (PIs) of between 21 and 41%, that increased with the degree of weathering. Blending of cinder gravels with the finer, weathered fraction should provide the plasticity required to achieve maximum dry density and prevent excessive gravel loss on gravel roads or from unsealed shoulders on paved roads. Figure 9 shows the plot of dry density versus moisture content for cinder gravel that has been repeatedly compacted by reusing the specimen. This simulates the condition in the field where the cinder gravel is broken down by compaction plant and trafficking in service to generate a fines content. Typical values of maximum dry density determined by this method ranged between 1.455 to 1.800 g/cm3. These values, and the optimum moisture contents they relate to, can be specified for construction purposes.

Cinder gravel blended with 10–20% plastic fines yielded CBRs well in excess of 15% @95% AASHTO T180, meaning that this material is suitable for subgrade replacement, for example where roads are to be constructed in areas of compressible or expandable clay soils. For use as sub-base, a minimum soaked CBR of 30% @97% AASHTO T180 is recommended for low-volume roads, and the cinder gravels were found to yield suitable values. Design CBRs for base course are dependent on the CBR strengths of the subgrade and sub-base and the traffic loading class, but the cinder gravel was found to yield suitable CBRs (minimum 45% @100% AASHTO T180) when blended with 20% plastic fines (weathered cinder gravel) and 30% crushed basalt rock. Based on the laboratory test results and the investigation and performance assessment of trial road sections, revised pavement design charts (one chart for climatic zone Weinert Number less than 4 and another for Weinert Number greater than 4) were developed for the use of cinder gravel as base course, based on subgrade CBR, blended cinder gravel CBR, traffic loading and pavement thickness.

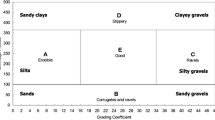

As gravel wearing course on unsealed roads, cinder gravel can achieve the requirements for maximum particle size, oversize index, grading coefficient, and soaked CBR, as specified in Table 1. However, the generally high water-absorption and the low 10% FACT values obtained (maximum was 60 kN) would ordinarily preclude the use of these cinder gravels in bituminous surface seals. Neither do they meet the criteria recommended by Overby (1999) for use in Otta seals (maximum water absorption of 2% and minimum 10% FACT of 90 kN). Nevertheless, cinder gravel materials of varying strength are being used as a graded gravel bituminous (Otta-type) seal in trial sections by the Ethiopian Roads Authority on roads with 75–100 vehicles per day. Preliminary results appear satisfactory, but at least 8 years of performance monitoring will be required before firm conclusions can be drawn.

The AIV test measures the percentage loss of particulate mass passing the 2.36 mm sieve following the application of 15 blows of a 14 kg hammer dropped from a height of 380 mm. Lower AIVs therefore correspond to stronger materials. The principal difference between the AIV and CBR test methods is the fact that the former tests a limited particle size range (10–14 mm) and a sample thickness of 50 mm, whereas the latter tests a sample with a size distribution of up to 19 mm and a sample thickness of 150 mm. The CBR is able to take account more readily of the bearing strength of the materials and the effects of clast to clast interlock. Nevertheless, the AIV is a rapid technique that can be performed on site (Fig. 10) and provides a useful preliminary assessment of material suitability. It, therefore, helps resolve some of the logistical issues concerning high volume sample transportation to the laboratory and facilitates more representative testing on site. Based on the work of Newill et al. (1987) and the laboratory testing and pavement performance assessments undertaken as part of this study, the following recommendations are made for the use of cinder gravel in pavement layers based on AIV:

-

Base layer materials should have an AIV of less than 40% (MAIVFootnote 2<60);

-

Sub-base and capping layer materials should have an AIV of less than 55% (MAIV<90).

Of a total 23 tests carried out, 15 yielded AIVs of 40% or less (suitable as base course) and all but one yielded AIVs of less than 55 (suitable as sub-base).

Figure 11 shows the relationship between AIV and bulk specific gravity for the cinder gravels investigated. As would be expected, there is a clear relationship that is controlled by the effects of vesicularity on density and hence material strength.

Cone morphology, mineralogy and field and laboratory test results

Cone morphology

A combination of remote sensing and field observation was used to derive simple geometric parameters for the sampled cones, maars and related features. These included base width and length (or diameter), height above ground level, side slope angle and diameter of summit (either with or without a crater). The remote sensing was based on Google Earth interpretation plus stereo analysis of black and white aerial photographs taken between 1965 and 1986 at a scale of 1:50,000. These aerial photographs pre-date almost all of the material extraction from the cinder cones and, therefore, record the original cone morphology. Comparison between these parameters and the field strength descriptions, simplified into low, moderate and high, failed to yield any definitive relationships and so the various landforms were classified into four main groups, as listed in Table 2. Recorded field strengths were averaged for each of these four landform categories, giving the distributions shown in Table 2. The strongest material is generally found in maars (less vesicular and with greater lithic content) and steep-sided, well-defined cones, with or without a summit crater. The weakest materials appear to occur in pyroclastic ridges or flow features.

Comparison of field and laboratory strengths

The geological assessment of field strength, using a geological hammer, is a qualitative method, but is rapid and obviously does not require the collection of samples. For prospecting purposes it is of interest, therefore, to compare the method with the AIV test, which provides a quantitative assessment of particle impact strength. AIV was used in the comparison, and not CBR, as CBR measures bulk bearing strength and not particle strength. The range and average of geological field strength, AIV and bulk specific gravity (BSG) were determined for each of the cluster areas shown in Fig. 1, and comparisons are made in Table 3. The field strength was again summarised into low, moderate and high, and the average for each cluster was determined. The variability in field strength for each cluster was also assessed and categorised into low, moderate and high. From Table 3 there is less than a clear relationship between field strength and either AIV or BSG. There are several reasons for this. First, there is evidently high variability within tephra, and especially cinder gravel deposits, both within cones and between cones in the same cluster. Second, the field description of strength is to some extent influenced by judgement, despite the guidelines set out in BS5930. Third, the field description was based on an assessment of a range of material sizes, including especially medium and coarse gravel and cobble-sized clasts, while the AIV test focuses on a narrow size range of medium gravel. Given that the strength of smaller-sized clasts may be influenced by weathering to a greater extent than the larger material, this is a potentially significant source of error, and therefore future studies should also determine the field strength of the actual AIV sample in addition to that of the in situ material.

Geographical distribution of cinder gravel strength

Materials with the highest average field strength and lowest variability offer the greatest potential for use in road construction, and samples from Injibara, Tulubolo and Asasa were optimum in this regard. In terms of maximum strength, samples from Injibara, Asasa and Butajira were among those ranked highest. The Bishoftu cluster also yielded material of moderate-high strength, but because of the large number of sampled locations, the variability was also high. For bulk specific gravity, Butajira, Injibara and Bishoftu gave the best results for the sampled materials. Samples from Bahir Dar, Adama Dera and Injibara had the lowest average AIV values, i.e. highest strengths. Injibara samples therefore appeared to contain consistently the better material. In contrast, samples from Hawassa ranked the lowest in terms of field-derived strength, AIV strength and bulk specific gravity. This geographical distribution of material strength appears to reflect the vesicularity of the cinder gravel: generally, the lower vesicular materials were found in the Injibara area and the higher in the Hawassa area.

Cinder gravel mineralogy and material strength

In addition to vesicularity, another possible explanation for geographical variation in cinder gravel strength is geochemical composition. Several publications describe the geochemistry of lavas in Ethiopia (e.g. Barberio et al. 1999; Boccaletti et al. 1999a, b; Chernet and Hart 1999; WoldeGabriel et al. 1999; Ayalew et al. 2003; Abebe et al. 2007; Meshesha and Shinjo 2007), but in the present study no clear relationship could be found between these descriptions and observed geographical variation in cinder gravel strength.

X-ray diffraction (XRD) and X-ray fluorescence (XRF) analyses were undertaken in order to study the mineralogy and chemical composition of cinder gravel samples collected by the present study. Results were averaged for each of the geographical cluster areas and are shown in Table 4. The average alkali (Na2O+ K2O) versus silica (SiO2) contents correspond to predominantly basaltic materials. Note that the results have not been normalised for volatile content or the oxidation state of iron and, therefore, a TAS (total alkali versus silica) Classification (e.g. Le Bas and Streckeisen 1991; Verma and Rivera-Gomez 2013) was not carried out.

Table 4 indicates that the geochemistry of the samples did not vary greatly between cluster areas, however there are some important differences. In the XRF data, these relate to the high MgO values for Injibara, Bahir Dar and Butajira, which correspond to their high forsterite contents (forsterite is the magnesium-rich end-member of the olivine mineral group), and the low Al2O3 and high Fe2O3 values for Hawassa. In the XRD data, important mineralogical differences include high and low values for plagioclase at Bishoftu and Injibara, respectively, high forsterite values at Butajira, Bahir Dar and Injibara (referred to above), high pyroxene values at Bahir Dar and Injibara, the very high value for haematite (Fe2O3) at Hawassa and the presence of nepheline at Bahir Dar. Nepheline is a felspathoid mineral typically found in silica-undersaturated igneous rocks. Compared with other areas, a high average goethite content was recorded in samples from Asasa. Goethite is an iron hydroxide derived from the weathering of other iron-rich minerals.

Ferromagnesian minerals (represented by pyroxene and forsterite) and calcium-rich varieties of plagioclase feldspar are particularly vulnerable to chemical weathering, while sodium-rich plagioclase is moderately susceptible. Samples with high contents of ferromagnesian minerals or plagioclase, such as those from Bahir Dar, Injibara and Bishoftu, may have been less affected by weathering and, therefore, potentially stronger. Samples with high haematite and goethite contents, such as those from Asasa and Hawassa, might represent more weathered materials that are potentially weaker. From Table 3, the Bahir Dar and Injibara materials were among the strongest in AIV tests, and those from Injibara were the strongest according to the geological field description. Hawassa samples were found to be the weakest in both AIV tests and field descriptions. Therefore, there is an apparent relationship between mineralogy, as an indicator of weathering state, and strength.

The Chemical Index of Alteration (CIA, Eq. 1, Nesbitt and Young 1982) measures the extent to which feldspar has been converted to aluminous weathering products, and is commonly used to characterise weathering profiles. CIA values typically range from 40 to 50 for weathered igneous rocks containing fresh feldspar to near 100 for kaolinite-rich residual soils. On this basis, the CIA values for the study samples, that ranged between 53 and 59, would indicate a low to moderate degree of chemical weathering.

The loss on ignition (LoI) provides an indication of the volatile content of a sample, principally clays (hydrous aluminium or magnesium silicates) and hydroxides (including goethite), together with carbon dioxide released from carbonates. Given the temperatures at which the cinder gravel was ejected (approximately 1000 °C) it is likely that all the weight loss is from secondary clay minerals produced by weathering and alteration. Fresh basalt has LoI values of about 1, while intensely weathered basalt has values of about 20. On this basis, the values in Table 4 suggest a low to moderate degree of weathering or alteration, consistent with the CIA values. The highest LoI value (3.00 for Asasa) is clearly related to the high goethite content. The reason for the next highest value (2.80 for Tulubolo) is unclear, but the relatively high CaO content could possibly indicate the presence of calcium carbonate as a secondary mineral. The lowest LoI (0.25) for Hawassa suggests that the high haematite content might be the product of late-stage volcanic activity (rather than chemical weathering) where the temperature-pressure conditions did not favour magnetite-ilmenite crystallisation.

The amorphous (non-crystalline) content of the samples was high, ranging from 18.5% (Hawassa) to 44% (Butajira), making any attempt at mineralogical analysis incomplete. Amorphous phases are not well understood, but in the present materials they probably consist mainly of volcanic glass together with varying amounts of secondary products, including hydrous iron oxides, colloidal silica and hydrous aluminium silicates (allophone). High volcanic glass contents reflect low crystallisation, resulting from effervescence (frothing) and sudden chilling of the magma. This may be the result of quenching during phreatomagmatic eruptions, but most of the sample locations are considered to have been subaerial. Moreover, quenching would have formed hydrated glass which probably would have resulted in higher LoI values than those found in this study.

The crystalline clay content of the cinder gravel samples was very low (approximately 1%), but samples from Alemgena-Tuludimptu had a higher content (7.5%). For blending purposes (see below), other samples were taken of material from the near-surface weathered horizon (upper 1-2 m) and these yielded combined illite, smectite and kaolinite clay contents of up to 30% (not represented in Table 4).

Regional variations in the degree of chemical weathering and alteration indicated by the geochemical data appear to both support and contradict the observed variability in average strength. This can probably be explained by the complex and variable sequence of emplacement and the post-formational processes that have determined the chemical and physical composition of these materials. The comparisons made using Tables 3 and 4 may, therefore, be petrologically and mechanically too simplistic and indeterminate, especially given the high amorphous contents recorded.

To conclude, XRF major element geochemistry does not appear to control the strength of the cinder gravel. The XRD data, however, may provide some insight into the weathering state of cinder gravel and, therefore, its likely strength and durability characteristics. The total clay, and in particular the expansive clay, content is of considerable significance to the engineering behaviour of the material and, from the limited data available, it would appear that material extracted from below the weathered horizon contains negligible expansive clay. However, blending operations, whereby the plasticity of the cinder materials is increased through the addition of fines, need to be careful not to introduce any expansive clays from the weathered horizon.

Performance of cinder gravels in constructed roads

The 110 km Alemgena-Butajira road is the oldest road in Ethiopia known to possess a cinder gravel sub-base. Approximately half of the road length was constructed with a blended cinder gravel sub-base and the other half with conventional weathered basalt, i.e. very different materials. The entire road has a crushed basalt base course. The road was constructed 15 years ago as a low-volume road, but traffic volumes have increased substantially since then. Two sections were selected for performance measurement and sampling. Rutting was measured, a traffic classification count made, and sub-base samples were taken for laboratory testing. The rut depth for both sections was regarded as fair (i.e. 5–15 mm) by Ethiopian Roads Authority standards. Moreover, the road carries an estimated 2.7 million ESAs of traffic in the heaviest loaded direction and has, therefore, become a relatively high-volume road. The blended cinder gravel has, therefore, performed very well as a low-cost sub-base material, despite it having a liquid limit of 50% and a PI of 26%, both of which are higher than the maximum recommended in the ERA (2017) Low-Volume Roads Design Manual (45 and 12%, respectively). Instead of using the PI as the defining parameter for cinder gravel sub-base suitability, it is recommended that the plasticity modulus (PM) be used instead. PM is a measure of the quantity of plastic fines in a material, it is expressed as plasticity index multiplied by the percentage of particles passing the 425 μm sieve, whereas plasticity index (PI) is only a measure of the magnitude of the plasticity, i.e. material stickiness.

Discussion

Material variability

Cinder gravel varies considerably: regionally; between cones in the same region; and between deposits within the same cone. It is probably one of the least predictable and most inconsistent of geomaterials, other than perhaps glacial till (e.g. Clarke 2017). This variability stems from inherent differences in vesicularity, which control porosity, water absorption and strength. Geochemistry seems to play little role in the determination of vesicularity, a property that is dictated primarily by dissolved volatile concentration in the magma chamber, evolution of the magma on its ascent to the Earth’s surface, the manner in which the material is erupted and the evolution of tephra in the eruptive column. Post-depositional modifications to the material include welding and chemical alteration brought about by heat flux and gas migration during the later phases of cone evolution and the longer-term oxidising effects of chemical weathering. Cinder gravel with high ferromagnesian mineral content is indicative of less weathered and stronger material, and there is a broad geographical pattern in this regard. However, from the available evidence, there appears to be little benefit in carrying out routine geochemical testing of the material for use in road construction, given the potential indeterminacy of the results. Generally, the grey-coloured materials were found to be stronger than the oxidised reddish-brown material, though there were some exceptions to this. For example, because of their very recent origin, many of the cinder gravel deposits observed in the Wonji Fault Belt are grey in colour, but they are also highly vesiculated and are often exposed as agglutinated spatter, which appears to be inherently weak (Fig. 12).

The geographical variability in cinder gravel strength appears to be less than the variability that occurs within individual cinder cones. Typical conditions comprise well-defined beds of alternating particle size, colour, vesicularity and strength. Alternate beds of the stronger material may vary between only 1 m and perhaps 10 m in thickness, thus complicating prospecting, sampling and effective exploitation. Again, there are exceptions, with entire cones in some instances being composed of either uniformly weak or, less frequently, uniformly strong material. Well-defined, steep-sided cones and maars have generally yielded the stronger materials, while low-amplitude domes, spatter cones and elongate “ridges” of pyroclastic materials and clastogenic lava have yielded the weakest materials. Nevertheless, there are exceptions to this general pattern as well.

Guideline for the use of cinder gravel in the road sector

The guideline developed as an output of this study (TRL 2018) included recommendations for prospecting, investigation, sampling and engineering use. Outline procedures for the use of remote sensing and field observation, ground investigation, sampling and testing are included in the guideline to ensure that borrow pits are properly selected for future exploitation. Quite often cinder gravel material can be observed within the exposed soil on natural hillsides and an examination of this material can indicate potentially the worst-case (weathered) condition of the material likely to be present at depth. Recommendations for the use of trial pitting, sampling and field-based AIV testing are made in order to provide an initial assessment of material quality prior to deciding which sources offer the greatest potential. Close liaison with the Environmental Protection Agency and the Geological Survey of Ethiopia, and other regulatory and statutory authorities, is also mandatory to avoid disturbing areas where there might be environmental concerns or where volcanic landforms are of special scientific or landscape interest.

The laboratory testing, combined with the performance assessment of existing cinder gravel road pavements, has demonstrated that most cinder gravel materials can be used in the construction of low-volume roads, either in their natural state or as blended materials, for capping layer, sub-base and base course. The guideline contains recommendations for material testing, subgrade preparation, blending mix design, pavement layer design, and construction method. The design of cinder gravel base courses with lime or cement stabilisation for use in heavily trafficked roads is also covered in the guideline, as are the operational limitations on the use of cinder gravels in bituminous surface seals and the techniques that can be applied to optimise their use. A summary of these recommendations is given in Box 1.

Conclusions

While it is fairly straight-forward to identify landforms containing cinder gravel (scoria) deposits using remote sensing and field observation, the inherent variability in the material means that the prediction of uniformity, size and strength is considerably more difficult. This study has examined the distribution of cinder gravel materials in different areas of Ethiopia to determine if broad relationships can be drawn between regional distribution, landform morphology, geochemistry and strength characteristics for purposes of future prospecting. While there are some useful associations that have emerged from this study, there still remains significant uncertainty as to what might be encountered in any new borrow pit excavation and, therefore, careful surface and subsurface investigation is required prior to opening up new borrow areas.

The use of cinder gravel as a road construction material is not new; it has been used experimentally in Ethiopia since the mid-1970s. These trials have proven successful, but the Ethiopian Roads Authority has been reluctant to use the material more widely as it has a tendency not to meet standard specifications for roadworks. This study has combined performance investigations with a programme of sampling and laboratory testing to develop a guideline that allows practitioners to use cinder gravel more widely and with greater confidence.

The potential benefits of using locally available cinder materials for road construction are likely to outweigh the costs incurred in prospecting and testing procedures. If they are exploited using the environmental protection measures and design criteria recommended in the guideline, their use will facilitate the provision of low-cost roads for rural communities in Ethiopia in the areas where these materials occur.

Notes

Less than 300 vehicles per day and up to one million equivalent standard axles (ESAs)

The Modified (M)AIV accounts for the breakdown of the aggregate during the progress of the test

References

Abebe T, Mazzarini F, Innocenti F, Manetti P (1998) The Yerer-Tullu Wellel volcanotectonic lineament: a transtensional structure in central Ethiopia and the associated magmatic activity. J Afr Earth Sci 26:135–150

Abebe B, Acocella V, Korme T, Ayalew D (2007) Quaternary faulting and volcanism in the Main Ethiopian Rift. J Afr Earth Sci 48:115–124

Adhana TA (2014) The occurrence of a complete continental rift type of volcanic rocks suite along the Yerer-Tullu Wellel Volcano Tectonic Lineament, Central Ethiopia. J Afr Earth Sci 99(2):374–385

Anon (2011) Maars and scoria cones: the enigma of monogenetic volcanic fields. Editorial. J Volcanol Geotherm Res 201:v–viii

Austroads (2011) Review of primes and primerseal Design. AP-T179/11. Austroads Ltd., Sydney

Ayalew D, Yirgu G, Ketefo E, Barbey P, Ludden J (2003) Intrusive equivalents of flood volcanics: evidence from petrology of xenoliths in Quaternary Tana basanites. Eth J Sci 26(2):93–102

Ayele A, Tadesse E, Segni G, Dessie K, Berhanu G (2002) Stabilization of cinder gravels with volcanic ash and cement. BSc disertation submitted to the University of Addis Ababa, Ethiopia

Bagdassarov NS, Dingwell DB, Wilding MC (1996) Rhyolite magma degassing: an experimental study of melt vesiculation. Bull Volcanol 57:587–601

Barberio MR, Donati C, Donato P, Yirgu G, Peccerillo A, Wu TW (1999) In: Boccaletti M, Peccerillo A (eds) The Ethiopian Rift System, Acta Vulcanologica, Journal of the National Volcanic Group of Italy, Volume II, Instituti Editoriali e Poligrafici Internazionali, Pisa/Roma, pp 69–81

Bemis KG, Ferencz M (2017) Morphometric analysis of scoria cones: the potential for inferring process from shape. In: Németh K, Carrasco-Nunez G, Aranda-Gomez JJ, Smith IEM (eds) Monogenetic volcanism. Geological Society of London, Special Publications, Geol Soc Lond Spec Publ 446:61–100

Bemis K, Walker J, Borgia A, Turrin B, Neri M, Swisher C (2011) The growth and erosion of cinder cones in Guatemala and El Salvador: models and statistics. J Volcanol Geotherm Res 201:39–52

Berhanu G (2009) Stabilizing cinder gravels for heavily trafficked base course. Journal of EAEA 26:23–29

Berhe SM, Desta B, Nicoletti M, Teferra M (1987) Geology, geochronology and geodynamic implications of the Cenozoic magmatic province in W and SE Ethiopia. J Geol Soc Lond 144:213–226

Boccaletti M, Mazzuoli R, Bonini M, Trua T, Abebe B (1999a) Plio-Quaternary volcanotectonic activity in the northern sector of the Main Ethiopian Rift: relationships with oblique rifting. J Afr Sci 29(4):679–698

Boccaletti M, Bonini M, Mazzuoli R, Trua T (1999b) Pliocene-Quaternary volcanism and faulting in the northern Main Ethiopian Rift (with two geological maps at scale 1:50,000). In: Boccaletti M, Peccerillo A (eds) The Ethiopian Rift System, Acta Vulcanologica, Journal of the National Volcanic Group of Italy, Volume II, Instituti Editoriali e Poligrafici Internazionali, Pisa/Roma, pp 83–97

Chernet T, Hart WK (1999) Petrology and geochemistry of volcanism in the northern Main Ethiopian Rift – southern Afar transition region. In: Boccaletti M, Peccerillo A (eds) The Ethiopian Rift System, Acta Vulcanologica, Journal of the National Volcanic Group of Italy, Volume II, Instituti Editoriali e Poligrafici Internazionali, Pisa/Roma, pp 21–41

Chorowicz J, Collet B, Bonavia FF, Mohr P, Parrot JF, Korme T (1998) The Tana basin, Ethiopia: intra-plateau uplift, rifting and subsidence. Tectonophysics 295:351–367

Clarke BG (2017) Engineering of glacial deposits. CRC Press, Taylor & Francis Group, Florida, USA

Dóniz-Páez J (2015) Volcanic geomorphological classification of the cinder cones of Tenerife (Canary Islands, Spain). Geomorphology 228:432–447

ERA (2017) Low volume roads design manual. Ethiopian Roads Authority, Addis Ababa

Eshete Y (2011) Blending of cinder with fine-grained soil to be used as a sub-base material (the case of the Butajira-Gubre road). MSc thesis submitted to the University of Addis Ababa, Ethiopia

Fornaciai A, Favalli M, Karátson D, Tarquini S, Boschi E (2012) Morphometry of scoria cones, and their relation to geodynamic setting: a DEM-based analysis. J Volcanol Geotherm Res 217:56–62

Hadera Z (2015) The potential use of cinder gravel as a base course material when stabilised by volcanic ash and lime. MSc thesis submitted to the University of Addis Ababa, Ethiopia.

Houghton B, Carey RJ (2015) Pyroclastic fall deposits. Chapter 34 In: The encyclopaedia of volcanoes, Elsevier, pp 599–616. https://doi.org/10.1016/B978-0-12-385,938-9.00034-1

Inbar I, Gilichinsky M, Melekestsev I, Melnikov D, Zaretskaya N (2011) Morphometric and morphological development of Holocene cinder cones: a field and remote sensing study in the Tolbachik volcanic field, Kamchatka. J Volcanol Geotherm Res 201:301–311

Kereszturi G, Németh K (2016) Sedimentology, eruptive mechanism and facies architecture of basaltic scoria cones from the Auckland Volcanic Field (New Zealand). J Volcanol Geotherm Res 324:41–56

Le Bas MJ, Streckeisen AL (1991) The IUGS systematics of igneous rocks. J Geol Soc Lond 148:825–833

Meshesha D, Shinjo R (2007) Crustal contamination and diversity of magma sources in the northwestern Ethiopian volcanic province. J Mineral Petrol Sci 102:272–290

Nesbitt HW, Young GM (1982) Early Proterozoic climate and plate motion inferred from major element chemistry of lutites. Nature 299:715–717

Newill D, Aklilu K (1980) The location and engineering properties of volcanic cinder gravels in Ethiopia, 7th Regional Conference for Africa on Soil Mechanics and Foundation Engineering, Accra, Ghana, 1–7 June 1980, pp 21–32

Newill D, Duffell C G, Black R E, Gulilat G (1979) Investigations of cinder gravels in Ethiopia 2. Road Trials JRRP Report No. 12, Ethiopian Roads Authority, Addis Ababa.

Newill D, Robinson R, Aklilu K (1987) Experimental use of cinder gravels on roads in Ethiopia. 9th Regional Conference fo Africa on Soil Mechanics and Foundation Engineering, Lagos, Nigeria, pp 467–488

Overby C (1999) Publication No. 93. A guide to the use of Otta Seals. Oslo: Directorate of Public Roads, Road Technology Department, International Division, Oslo, Norway

Paige-Green P (1989) The Influence of geotechnical properties on the performance of gravel wearing course materials. PhD Thesis. University of Pretoria, Pretoria

Rooney TR, Bastow ID, Keir D (2011) Insights into extensional processes during magma assisted rifting: evidence from aligned scoria cones. J Volcanol Geotherm Res 201:83–96

Settle M (1979) The structure and emplacement of cinder cone fields. Am J Sci 279:1089–1107

Smith IEM, Németh K (2017) Source to surface model of monogenetic volcanism: a critical review. In: Németh K, Carrasco-Nunez G, Aranda-Gomez JJ, Smith IEM (eds) Monogenetic volcanism, Geol Soc Lond Spec Publ 446: 1–28

Sparks RSJ, Bursik MI, Carey SN, Gilbert JS, Glaze L, Sigurdsson H, Woods AW (1997) Volcanic Plumes. Wiley, Chichester

TRL (1993) A guide to the structural design of bitumen-surfaced roads in tropical and sub-tropical countries (4th Edn). Overseas Road Note 31. Transport Research Laboratory, Crowthorne, Berkshire, UK

TRL (2018) Guideline for the use of cinder gravels in pavement layers for low-volume roads. Prepared for the Ethiopian Roads Authority by the Transport Research Laboratory through the Africa Community Access Programme procured by Cardno Emerging Markets UK Ltd. on behalf of the UK Department for International Development

Uslular G, Gençalioğlu-Kuşcu G, Arcasoy A (2015) Size-distribution of scoria cones within the Eğrikuyu Monogenetic Field (Central Anatolia, Turkey). J Volcanol Geotherm Res 301:56–65

Valentine GA, Krier DJ, Perry FV, Heiken G (2007) Eruptive and geomorphic processes at the Lathrop Wells scoria cone volcano. J Volcanol Geotherm Res 161:57–80

Verma SP, Rivera-Gomez MA (2013) Computer programs for the classification and nomenclature of igneous rocks. Episodes 36(2):115–124

Walker GPL (1993) Basaltic-volcano system. In: Prichard HM, Alabaster T, Harris NBW, Neary CR (Eds) Magmatic processes and plate tectonics. Geol Soc Sp Pub 76:3–38

WoldeGabriel G, Walter RC, Hart WK, Mertzman SA, Aronson JL (1999) Temporal relations and geochemical features of the felsic volcanism in the central section of the Main Ethiopian Rift. In: Boccaletti M, Peccerillo A (eds) The Ethiopian Rift System, Acta Vulcanologica, Journal of the National Volcanic Group of Italy, Volume II, Instituti Editoriali e Poligrafici Internazionali, Pisa/Roma, pp 53–67

Wood CA (1980a) Morphometric analysis of cinder cone degradation. J Volcanol Geotherm Res 8:137–160

Wood CA (1980b) Morphometric evolution of cinder cones. J Volcanol Geotherm Res 7:387–413

World Bank (2016) New rural access index: main determinants and correlation to poverty. Policy Research Working Paper WPS 7876, Washington DC

Acknowledgements

The authors would like to thank the staff of the Ethiopian Roads Authority (ERA) for assisting with this study. In particular, the assistance provided by all staff at the soils laboratory, Road Research Centre, is gratefully acknowledged. Discussion and comments were provided by T Rooney, R Sparks and G Yirgu. J Wilkins of X Ray Minerals Ltd. provided useful discussion on the XRD/XRF data. Comments on a draft of this paper provided by G Pettifer, especially with regard to geochemistry, are gratefully acknowledged, as are those provided by two anonymous reviewers. The study was undertaken by the Transport Research Laboratory (TRL) UK in association with ERA as part of the Africa Community Access Partnership (AfCAP), managed by Cardno Emerging Markets and sponsored by the Department for International Development (DFID). The views expressed in this publication are not necessarily those of AfCAP, DFID or Cardno Emerging Markets.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Hearn, G.J., Otto, A., Greening, P.A.K. et al. Engineering geology of cinder gravel in Ethiopia: prospecting, testing and application to low-volume roads. Bull Eng Geol Environ 78, 3095–3110 (2019). https://doi.org/10.1007/s10064-018-1333-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-018-1333-3