Abstract

Purpose

To evaluate the osteoconductivity and the bonding strength of the newly developed interbody cage covered with the porous titanium sheet (porous Ti cage) to vertebral bodies in a sheep model.

Methods

Twelve sheep underwent anterior lumbar interbody fusion at L2–3 and L4–5 using either the new porous Ti cages (Group-P) or conventional Ti cages with autogenous iliac bone (Group-C). The animals were euthanized at 2 or 4 months postoperatively and subjected to radiological, biomechanical, and histological examinations.

Results

Computed tomography analyses showed that the ratio of bone contact area in Group-P was significantly increased at 4 months compared with that at 2 months (p = 0.01). Although the ratio of bone contact area in Group-C was significantly higher than Group-P at 2 months (p < 0.001), there was no statistically significant difference between the two groups at 4 months. Biomechanical test showed that there was no significant difference in bonding strength between the two groups at either 2 or 4 months. Histological analyses revealed that the bone apposition ratio increased significantly with time in Group-P (p < 0.001). Although Group-C showed significantly higher bone apposition ratio than Group-P at 2 months (p = 0.001), there was no statistical difference between the two groups at 4 months.

Conclusions

There was bone ingrowth into the porous Ti sheet, and bonding capacity of the porous Ti cage to the host bone increased with time. However, the speed of union to the bone with a porous Ti cage was marginally lower than a conventional cage along with an autogenous bone graft. Although it needs further experiment with a larger sample size, the results of the current study suggested that this material could achieve interbody fusion without the need for bone grafts.

Similar content being viewed by others

References

Zhou ZJ, Zhao FD, Fang XQ, Zhao X, Fan SW (2011) Meta-analysis of instrumented posterior interbody fusion versus instrumented posterolateral fusion in the lumbar spine. J Neurosurg Spine 15(3):295–310

Rihn JA, Patel R, Makda J, Hong J, Anderson DG, Vaccaro AR, Hilibrand AS, Albert TJ (2009) Complications associated with single-level transforaminal lumbar interbody fusion. Spine J 9(8):623–629

Rihn JA, Kirkpatrick K, Albert TJ (2010) Graft options in posterolateral and posterior interbody lumbar fusion. Spine (Phila Pa 1976) 35(17):1629–1639

Abbushi A, Cabraja M, Thomale UW, Woiciechowsky C, Kroppenstedt SN (2009) The influence of cage positioning and cage type on cage migration and fusion rates in patients with monosegmental posterior lumbar interbody fusion and posterior fixation. Eur Spine J 18(11):1621–1628

Alvarez K, Nakajima H (2009) Metallic scaffolds for bone regeneration. Materials 2(3):790–832

Ryan G, Pandit A, Apatsidis DP (2006) Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials 27(13):2651–2670

Hanzlik JA, Day JS (2013) Bone ingrowth in well-fixed retrieved porous tantalum implants. J Arthroplasty 28(6):922–927

Murata M, Akazawa T, Tazaki J, Ito K, Sasaki T, Yamamoto M, Tabata Y, Arisue M (2007) Blood permeability of a novel ceramic scaffold for bone morphogenetic protein-2. J Biomed Mater Res B Appl Biomater 81(2):469–475

Akazawa T, Murata M, Sasaki T, Tazaki J, Kobayashi M, Kanno T, Nakamura K, Arisue M (2006) Biodegradation and bioabsorption innovation of the functionally graded bovine bone-originated apatite with blood permeability. J Biomed Mater Res A 76(1):44–51

Sakamoto M, Nakasu M, Matsumoto T, Okihana H (2007) Development of superporous hydroxyapatites and their examination with a culture of primary rat osteoblasts. J Biomed Mater Res A 82(1):238–242

Sakamoto M, Matsumoto T (2012) Development and evaluation of superporous ceramics bone tissue scaffold materials with triple pore structure A) hydroxyapatite, B) Beta-Tricalcium phosphate. Haim Tal Bone Regeneration Croatia: In Tech:301–320

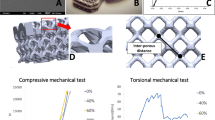

Kato K, Yamamoto A, Ochiai S, Daigo Y, Isobe T, Matano S, Omori K (2012) Cell proliferation, corrosion resistance and mechanical properties of novel titanium foam with sheet shpase. Mater Trans 53(4):724–732

Kato K, Ochiai S, Yamamoto A, Daigo Y, Honma K, Matano S, Omori K (2013) Novel multilayer Ti foam with cortical bone strength and cytocompatibility. Acta Biomater 9(3):5802–5809

Ito M, Kotani Y, Hojo Y, Abumi K, Kadosawa T, Minami A (2007) Evaluation of hydroxyapatite ceramic vertebral spacers with different porosities and their binding capability to the vertebral body: an experimental study in sheep. J Neurosurg Spine 6(5):431–437

Lee JH, Jeon DW, Lee SJ, Chang BS, Lee CK (2010) Fusion rates and subsidence of morselized local bone grafted in titanium cages in posterior lumbar interbody fusion using quantitative three-dimensional computed tomography scans. Spine (Phila Pa 1976) 35(15):1460–1465

Motomiya M, Ito M, Takahata M, Kadoya K, Irie K, Abumi K, Minami A (2007) Effect of Hydroxyapatite porous characteristics on healing outcomes in rabbit posterolateral spinal fusion model. Eur Spine J 16(12):2215–2224

Assad M, Jarzem P, Leroux MA, Coillard C, Chernyshov AV, Charette S, Rivard CH (2003) Porous titanium-nickel for intervertebral fusion in a sheep model: part 1. Histomorphometric and radiological analysis. J Biomed Mater Res B Appl Biomater 64(2):107–120

Takemoto M, Fujibayashi S, Neo M, So K, Akiyama N, Matsushita T, Kokubo T, Nakamura T (2007) A porous bioactive titanium implant for spinal interbody fusion: an experimental study using a canine model. J Neurosurg Spine 7(4):435–443

Zou X, Li H, Bünger M, Egund N, Lind M, Bünger C (2004) Bone ingrowth characteristics of porous tantalum and carbon fiber interbody devices: an experimental study in pigs. Spine J 4(1):99–105

Zou X, Li H, Teng X, Xue Q, Egund N, Lind M, Bünger C (2005) Pedicle screw fixation enhances anterior lumbar interbody fusion with porous tantalum cages: an experimental study in pigs. Spine (Phila Pa 1976) 30(14):E392–E399

Long M, Rack HJ (1998) Titanium alloys in total joint replacement—a materials science perspective. Biomaterials 19(18):1621–1639

Colnot C (2011) Cell sources for bone tissue engineering: insights from basic science. Tissue Eng Part B Rev 17(6):449–457

Wilke HJ, Kettler A, Claes LE (1997) Are sheep spines a valid biomechanical model for human spines? Spine (Phila Pa 1976) 22(20):2365–2374

Hojo Y, Kotani Y, Ito M, Abumi K, Kadosawa T, Shikinami Y, Minami A (2005) A biomechanical and histological evaluation of a bioresorbable lumbar interbody fusion cage. Biomaterials 26(15):2643–2651

Acknowledgments

We thank Toshio Matsumoto, B.S. and Takehiko Nakajima, B.S., HOYA Pentax Co., for their technical support and providing Ti porous materials and downsized intervertebral spacers for the animals. Furthermore, we thank Ken Nagahama, M.D., Ph.D. for his support in performing the surgery and to Fumio Sasazawa, M.D., Ph.D for capturing CT images. This study was supported by HOYA Pentax Co., Start-up Grant of Northern Advancement Center for Science & Technology, and Strategic Promotion of Innovative Research and Development, Japan Science and Technology Agency.

Conflict of interest

Manabu Ito has received research grants from HOYA-Pentax, Co., Robert-Reid, Inc and Century-Medical, Co., and is a board member of AOSpine Knowledge Forum. Toru Yamamoto has received endowments from Mizuho Ikakogyo, Co., Ltd. The other authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yamada, K., Ito, M., Akazawa, T. et al. A preclinical large animal study on a novel intervertebral fusion cage covered with high porosity titanium sheets with a triple pore structure used for spinal fusion. Eur Spine J 24, 2530–2537 (2015). https://doi.org/10.1007/s00586-015-4047-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00586-015-4047-2