Abstract

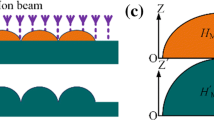

A cost-effective fabrication method for high quality and high fill-factor aspheric microlens arrays (MLAs) is developed. In this method, the complex shape of aspheric microlens is pre-modeled via dose modulation in a digital micromirror device (DMD) based maskless projection lithography system. Digital masks for several bottom layers are replaced from circle to hexagon for the purpose of enhancing the fill-factor of MLAs, then a low temperature thermal reflow process is conducted, after which the average surface roughness of microlens is improved to ~ 0.427 nm while the pre-modeled profile keeps unchanged. Experimental results show that the fabricated aspheric MLAs have almost 100% fill-factor, high shape accuracy and high surface quality. The presented method may provide a promising approach for rapidly fabricating high quality and high fill-factor aspheric microlens in a simple and low-cost way.

Similar content being viewed by others

References

Chen Y et al (2015) Reducing optical losses in organic solar cells using microlens arrays: theoretical and experimental investigation of microlens dimensions. Phys Chem Chem Phys 17(5):3723–3730

Chung CK, Hong YZ (2007) Fabrication and analysis of the reflowed microlens arrays using JSR THB-130 N photoresist with different heat treatments. Microsyst Technol 13(5–6):523–530

Hahn DV et al (2010) Fiber optic bundle array wide field-of-view optical receiver for free space optical communications. Opt Lett 35(21):3559–3561

Huang S et al (2017) Improved slicing strategy for digital micromirror device-based three-dimensional lithography with a single scan. Micro Nano Lett 12(1):49–52

Huang S et al (2018) Fabrication of high quality aspheric microlens array by dose-modulated lithography and surface thermal reflow. Opt Laser Technol 100:298–303

Li L, Allen YY (2012) Design and fabrication of a freeform microlens array for a compact large-field-of-view compound-eye camera. Appl Opt 51(12):1843–1852

Lin CP, Yang H, Chao CK (2003) Hexagonal microlens array modeling and fabrication using a thermal reflow process. J Micromech Microeng 13(5):775

Park MK et al (2014) Design and fabrication of multi-focusing microlens array with different numerical apertures by using thermal reflow method. J Opt Soc Korea 18(1):71–77

Vekshin MM et al (2010) Glass microlens arrays for Shack-Hartmann wavefront sensors. Meas Sci Technol 21(5):3–143

Wu CY, Chiang TH, Hsu CC (2008) Fabrication of microlens array diffuser films with controllable haze distribution by combination of breath figures and replica molding methods. Opt Express 16(24):19978–19986

Wu D et al (2009) 100% fill-factor aspheric microlens arrays (AMLA) with sub-20-nm precision. IEEE Photonics Technol Lett 21(20):1535–1537

Yang H et al (2004) High fill-factor microlens array mold insert fabrication using a thermal reflow process. J Micromech Microeng 14(8):1197

Zhong K, Zhang H, Gao Y (2017) Fabrication of high fill-factor aspheric microlens array by digital maskless lithography. Optik-Int J Light Electron Opt 142:243–248

Zhu Z, To S, Zhang S (2015) Large-scale fabrication of micro-lens array by novel end-fly-cutting-servo diamond machining. Opt Express 23(16):20593–20604

Acknowledgements

This work was supported by funding from the National Natural Science Foundation of China (Grant No. 51475442), the Fundamental Research Funds for the Central Universities, and partially carried out at the University of Science and Technology of China Center for Micro and Nanoscale Research and Fabrication.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, J., Li, M., Qiu, J. et al. Fabrication of high fill-factor aspheric microlens array by dose-modulated lithography and low temperature thermal reflow. Microsyst Technol 25, 1235–1241 (2019). https://doi.org/10.1007/s00542-018-4226-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-4226-2