Abstract

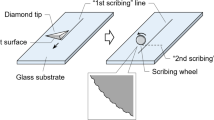

Out-of-plane microlens, as its in-plane counterpart, is an important micro optics component that can be used in building integrated micro-optic systems for many applications. In earlier publications from our group, an ultra violet (UV) lithography based technique for out-of-plane microlens fabrication was reported. In this paper, we report a replication technology for time-efficient fabrication of out-of-plane microlens made of a curable polymer, NOA73. Microlens of cured SU-8 polymer was fabricated using a unique tilted UV lithography process, polydimethylsiloxane (PDMS) was molded using the resulting SU-8 master to form a negative mold, curable polymer NOA73 was then casted in the PDMS mold and out-of-plane microlens replica made of NOA73 was finally obtained after curing. The entire replication process took less than 5 h. Since PDMS negative mold was reusable, multiple replications of the microlens could be done with the same mold and each replication only took about 30 min. Scanning electron microscopic (SEM) images showed that NOA73 microlens replica had almost identical shape as the SU-8 master. In Comparison to the SU-8 microlens, microlens replica of UV curable polymer had slightly longer focal length and smaller numerical aperture due to the lower refractive index of NOA73. In addition, NOA73 microlens replica also had improved spectral transmission. Because of its compatibility with soft lithography technique, the reported replication process may also be used to integrate out-of-plane microlens into micro-opto-electro-mechanical-systems (MOEMS) and BioMEMS chips.

Similar content being viewed by others

References

Arai J, Kawai H, Okano F (2006) Microlens array for integral imaging system. Appl Opt 45(35):9066–9078

Hecht E (2001) Optics, 4th edn. Benjamin Cummings, San Francisco

Jeong KH, Kim JY, Lee LP (2006) Biologically inspired artificial compound eyes. Science 312:557–561

Kou JN, Hsieh CC, Yang SY et al (2007) An SU-8 microlens array fabricated by soft replica molding for cell counting applications. J Micromech Microeng. doi:10.1088/0960-1317/17/4/004

Kwon H, Yee Y, Jeong CH et al (2008) A high-sag microlens array film with a full fill factor and its application to organic light emitting diodes. J Micromech Microeng. doi:10.1088/0960-1317-18/6/065003

LaFratta CN, Li LJ, Fourkas JT (2006) Soft-lithographic replication of 3D microstructures with closed loops. PNAS 103(23):8589–8594

Martinez-Corral M, Javidi B, Matinez-Cuenca R et al (2004) Integral imaging with improved depth of field by use of amplitude-modulated microlens arrays. Appl Opt 43(31):5806–5813

McDonald JC, Duffy DC, Anderson JR et al (2000) Fabrication of microfluidic systems in poly(dimethylsioxane). Electrophoresis 21:27–40

Nussbaum P, Volkel R, Herzig HP et al (1997) Design, fabrication and testing of microlens arrays for sensors and microsystems. Pure Appl Opt 6:617–636

Roy E, Voisin B, Gravel JF et al (2009) Microlens array fabrication by enhanced thermal reflow process: towards efficient collection of fluorescence light from microarrays. Microelect Eng 86(11):2255–2261

Sato H, Yagyu D, Seiki I et al (2006) Improved inclined multi-lithography using water as exposure medium and its 3D mixing microchannel application. Sens Actuators A 128:183–190

Shimura D, Sehikawa R, Kotani K et al (2006) Bidirectional optical subassembly with prealigned silicon microlens and laser diode. IEEE Photon Technol Lett 18(16):1738–1740

Yang R, Wang WJ (2004) Out-of-plane polymer refractive microlens fabricated based on direct lithography of SU-8. Sens Actuators A 113(1):71–77

Yang R, Wang WJ, Soper SA, (2005) Out of-plane microlens array fabricated using ultraviolet lithography. Appl Phys Lett 86:16110-1–16110-3

Acknowledgments

This work is supported by the National Science Foundation under Grant Number ECS-0524626. The authors would also like to thank Center for Advanced Microstructures & Devices (CAMD) at Louisiana State University for cleanroom access.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, G., Qiu, W. & Wang, W. Fast replication of out-of-plane microlens with polydimethylsiloxane and curable polymer (NOA73). Microsyst Technol 16, 1471–1477 (2010). https://doi.org/10.1007/s00542-009-1010-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-009-1010-3