Abstract

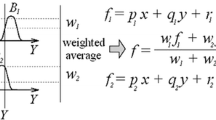

In the present work, layer thickness of duplex coating made from thermo-reactive deposition and diffusion has been predicted by Adaptive network-based fuzzy inference systems (ANFIS). A duplex surface treatment on five steels has been developed involving nitrocarburizing and followed by chromium thermo-reactive deposition (TRD) techniques. The TRD process was performed in molten salt bath at 550, 625 and 700 °C for 1–30 h. The process formed a thickness up to 9.5 μm of chromium carbonitride coatings on a hardened diffusion zone. A model based on ANFIS for predicting the layer thickness of duplex coating of the specimens has been presented. To build the model, training and testing using experimental results from 84 specimens were conducted. The data used as inputs in ANFIS models are arranged in a format of twelve parameters that cover the chemical composition (C, Mn, Si, Cr, Mo, V, W), the pre-nitriding time, ferro-chromium particle size, ferro-chromium weight percent, salt bath temperature and coating time. According to these input parameters, in the Adaptive network-based fuzzy inference system models, the layer thickness of duplex coating of each specimen was predicted. The training and testing results in ANFIS models have shown a strong potential for predicting the layer thickness of duplex coating.

Similar content being viewed by others

References

Bertrand G, Savall C, Meunier C (1997) Propertied of reactively RF magnetron-sputtered chromium nitride coatings. Surf Coat Technol 96:323–329

Kig PC, Reynoldson RW, Brownrigg A, Long JM (2004) Cr(N, C) diffusion coating formation on pre-nitrocarburised H13 tool steel. Surf Coat Technol 179:18–26

Chicco B, Borbidge WE, Summerville E (1999) Experimental study of carbide and carbonitride coatings. Mater Eng A226:62–72

Arai T (1987) Diffusion carbide coatings formed in molten borax systems. J Mater Eng 2(2):183–1893

Chang DY, Lee SY, Kang S-G (1999) Effect of plasma nitriding on the surface properties of the chromium diffusion coating layer in iron-base alloys. Surf Coat Technol 116–119:391–397

Zum Gahr K-H (1987) Microstructure and wear of materials. Elsevier Science Publishers B.V., tribology series, 10, pp 84–108, 496–524

Jongbloed RC (1994) Chromizing. Mater Sci Forum 163–165:611–618

Zancheva L, Hillert M, Lange N, Seetharaman S, Staffansson LI (1978) On the formation of carbide coatings by chromizing carbon steels. Metall Trans A 9:909–915

Arai T, Endo J, Takeda H (1987) Chromizing and boriding by use of a fluidized bed. Ind Heat 54(8):18–19

Chen F-S, Lee P-Y, Yeh M-C (1998) Thermal reactive deposition coating of chromium carbide on die steel in a fluidized bed furnace. Mater Chem Phys 53:19–27

Nazari A, Milani AA (2011) Modeling ductile to brittle transition temperature of functionally graded steels by artificial neural networks. Comput Mater Sci 50:2028–2037

Nazari A, Milani AA (2011) Modeling ductile to brittle transition temperature of functionally graded steels by fuzzy logic. J Mater Sci 46:6007–6017

Nazari A, Riahi S (2010) Computer-aided prediction of physical and mechanical properties of high strength cementitious composite containing Cr2O3 nanoparticles. Nano 5(5):301–318

Nazari A, Riahi S (2011) Prediction split tensile strength and water permeability of high strength concrete containing TiO2 nanoparticles by artificial neural network and genetic programming. Compos B Eng 42:473–488

Nazari A, Riahi S (2011) Computer-aided design of the effects of Fe2O3 nanoparticles on split tensile strength and water permeability of high strength concrete. Mater Des 32:3966–3979

Nazari A, Didehvar N (2011) Modeling impact resistance of aluminum-epoxy laminated composites by ANFIS. Compos Part B: Eng 42:1912–1919

Jang JSR (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cyber 23(3):665–685

Sarıdemir M (2009) Predicting the compressive strength of mortars containing metakaolin by artificial neural networks and fuzzy logic. Adv Eng Softw 40(9):920–927

Wahl G (1980) Salt bath nitriding—Tufftride TF1-AB1. Technical pamphlet from Degussa, Hanau

Sricharoenchai P, Pornnimitthum S, Bhandhbanyong P (1998) Coating tool steel with niobium carbide by TRD process. In: The 1st international automotive heat treating conference, ASM International, pp 391–394

Khalaj G (2012) Artificial neural network to predict the effects of coating parameters on layer thickness of chromium carbonitride coating on pre-nitrided steels. Neural Comput Appl. doi:10.1007/s00521-012-0994-2

Arai T, Fujita H, Sugimoto Y, Ohta Y (1988) Proceedings of the 6th international congress on heat treatment of materials, ASM International, USA, p 49

Sen U, Sen S, Yilmaz F (2004) Structural characterization of boride layer on boronized ductile irons. Surf Coat Technol 176:222

Ozbek I, Bindal C (2002) Mechanical properties of boronized AISI W4 steel. Surf Coat Technol 154:14

Tsipas DN, Rus J (1987) Boronizing of alloy steels. J Mater Sci Lett 6:118

Ramezanianpour AA, Sobhani M, Sobhani J (2004) Application of network based neuro-fuzzy system for prediction of the strength of high strength concrete. Amirkabir J Sci Technol 5(59-C):78–93

Ramezanianpour AA, Sobhani J, Sobhani M (2004) Application of an adaptive neurofuzzy system in the prediction of HPC compressive strength. In: Proceedings of the fourth international conference on engineering computational technology, Civil-Comp Press, Lisbon, Portugal, p 138

Topcu IB, Sarıdemir M (2008) Prediction of mechanical properties of recycled aggregate concretes containing silica fume using artificial neural networks and fuzzy logic. Comput Mater Sci 42(1):74–82

Jang JSR, Sun CT (1995) Nuro-fuzzy modeling and control. Proc IEEE 83(3):378–406

Guzelbey IH, Cevik A, Erklig A (2006) Prediction of web crippling strength of cold-formed steel sheetings using neural networks. J Constr Steel Res 62:962–973

Guzelbey IH, Cevik A, Gögüs MT (2006) Prediction of rotation capacity of wide flange beams using neural networks. J Constr Steel Res 62:950–961

Cevik A, Guzelbey IH (2008) Neural network modeling of strength enhancement for CFRP confined concrete cylinders. Build Environ 43:751–763

Cevik A, Guzelbey IH (2007) A soft computing based approach for the prediction of ultimate strength of metal plates in compression. Eng Struct 29(3):383–394

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalaj, G., Khalaj, MJ. Application of ANFIS for modeling of layer thickness of chromium carbonitride coating. Neural Comput & Applic 24, 685–694 (2014). https://doi.org/10.1007/s00521-012-1290-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-012-1290-x