Abstract

Deformation of soft polymeric materials often involves complex nonlinear or transient mechanical behaviors. This is due to the dynamic behaviors of polymer chains at the molecular level within the polymer network. In this paper, we present a computational formulation to describe the transient behavior (e.g., viscoelasticity) of soft polymer networks with dynamic bonds undergoing large to extreme deformation. This formulation is based on an Eulerian description of kinematics and a theoretical framework that directly connects the molecular-level kinetics of dynamic bonds to the macroscopic mechanical behavior of the material. An extended finite element method is used to discretize the field variables and the governing equations in an axisymmetric domain. In addition to validating the framework, this model is used to study how the chain dynamics affect the macroscopic response of material as they undergo a combination of flow and elasticity. The problems of cavitation rheology and polymer indentation under extreme deformation are investigated in this context.

Similar content being viewed by others

References

Akalp U, Bryant SJ, Vernerey FJ (2016) Tuning tissue growth with scaffold degradation in enzyme-sensitive hydrogels: a mathematical model. Soft Matter 12(36):7505–7520

Asbury JB, Steinel T, Fayer MD (2004) Hydrogen bond networks: structure and evolution after hydrogen bond breaking. J Phys Chem B 108(21):6544–6554

Bathe K-J (2001) The inf–sup condition and its evaluation for mixed finite element methods. Comput Struct 79(2):243–252

Bathe K-J (2006) Finite element procedures. Prentice-Hall, Upper Saddle River

Bathe K-J, Wilson EL (1976) Numerical methods in finite element analysis, vol 197. Prentice-Hall, Upper Saddle River

Benet E, Vernerey FJ (2016) Mechanics and stability of vesicles and droplets in confined spaces. Phys Rev E 94(6):062613

Benson DJ (1992) Computational methods in lagrangian and eulerian hydrocodes. Comput Methods Appl Mech Eng 99(2–3):235–394

Bergström JS, Boyce MC (2001) Constitutive modeling of the time-dependent and cyclic loading of elastomers and application to soft biological tissues. Mech Mater 33(9):523–530

Chapelle D, Bathe K-J (1993) The inf–sup test. Comput Struct 47(4–5):537–545

Chia HN, Wu BM (2015) Recent advances in 3D printing of biomaterials. J Biol Eng 9(1):4

Choi YJ, Hulsen MA (2012) Alignment of particles in a confined shear flow of a viscoelastic fluid. J Non-Newton Fluid Mech 175:89–103

Choi Y, Hulsen MA, Meijer HEH (2010) An extended finite element method for the simulation of particulate viscoelastic flows. J Non-Newton Fluid Mech 165(11–12):607–624

Choi YJ, Hulsen MA, Meijer HEH (2012) Simulation of the flow of a viscoelastic fluid around a stationary cylinder using an extended finite element method. Comput Fluids 57:183–194

Christensen RM, Freund LB (1971) Theory of viscoelasticity. J Appl Mech 38:720

De Gennes PG, Leger L (1982) Dynamics of entangled polymer chains. Ann Rev Phys Chem 33(1):49–61

de Gennes PG (1992) Reptation of a polymer chain in the presence of fixed obstacles. Simple Views Condens Matter 4:148

Doi M (2013) Soft matter physics. Oxford University Press, Oxford

Donea J, Giuliani S, Halleux J-P (1982) An arbitrary Lagrangian–Eulerian finite element method for transient dynamic fluid–structure interactions. Comput Methods Appl Mech Eng 33(1–3):689–723

Dowling NE (2012) Mechanical behavior of materials: engineering methods for deformation, fracture, and fatigue. Pearson, Pearson

Duddu R, Lavier LL, Hughes TJR, Calo VM (2012) A finite strain Eulerian formulation for compressible and nearly incompressible hyperelasticity using high-order b-spline finite elements. Int J Numer Methods Eng 89(6):762–785

Étienne J, Hinch EJ, Li J (2006) A Lagrangian–Eulerian approach for the numerical simulation of free-surface flow of a viscoelastic material. J Non-Newton Fluid Mech 136(2–3):157–166

Fakhouri S, Hutchens SB, Crosby AJ (2015) Puncture mechanics of soft solids. Soft Matter 11(23):4723–4730

Farsad M, Vernerey FJ (2012) An XFEM-based numerical strategy to model mechanical interactions between biological cells and a deformable substrate. Int J Numer Methods Eng 92(3):238–267

Farsad M, Vernerey FJ, Park HS (2010) An extended finite element/level set method to study surface effects on the mechanical behavior and properties of nanomaterials. Int J Numer Methods Eng 84(12):1466–1489

Foucard L, Aryal A, Duddu R, Vernerey F (2015) A coupled Eulerian–Lagrangian extended finite element formulation for simulating large deformations in hyperelastic media with moving free boundaries. Comput Methods Appl Mech Eng 283:280–302

Foucard L, Vernerey FJ, and (2016) A particle-based moving interface method (PMIM) for modeling the large deformation of boundaries in soft matter systems. Int J Numer Methods Eng 107(11):923–946

Foucard LC, Pellegrino J, Vernerey FJ (2014) Particle-based moving interface method for the study of the interaction between soft colloid particles and immersed fibrous network. Comput Model Eng Sci 98(1):101–127

Foucard LC, Vernerey FJ (2015) An X-FEM-based numerical-asymptotic expansion for simulating a stokes flow near a sharp corner. Int J Numer Methods Eng 102(2):79–98

Fourche G (1995) An overview of the basic aspects of polymer adhesion. Part i: fundamentals. Polym Eng Sci 35(12):957–967

Gent AN, Lindley PB (1959) Internal rupture of bonded rubber cylinders in tension. In: Proceedings of the royal society of London A: mathematical, physical and engineering sciences, vol 249. The Royal Society, pp 195–205

Grillet AM, Wyatt NB, Gloe LM (2012) Polymer gel rheology and adhesion. In: Rheology. InTech

Hager MD, Greil P, Leyens C, van der Zwaag S, Schubert US (2010) Self-healing materials. Adv Mater 22(47):5424–5430

Harlen OG, Rallison JM, Szabo P (1995) A split Lagrangian–Eulerian method for simulating transient viscoelastic flows. J Non-Newton Fluid Mech 60(1):81–104

Holzapfel GA (2002) Nonlinear solid mechanics: a continuum approach for engineering science. Meccanica 37(4):489–490

Holzapfel GA, Gasser TC (2001) A viscoelastic model for fiber-reinforced composites at finite strains: continuum basis, computational aspects and applications. Comput Methods Appl Mech Eng 190(34):4379–4403

Hughes TJR, Liu WK, Zimmermann TK (1981) Lagrangian–Eulerian finite element formulation for incompressible viscous flows. Comput Methods Appl Mech Eng 29(3):329–349

Kalcioglu ZI, Mahmoodian R, Hu Y, Suo Z, Van Vliet KJ (2012) From macro-to microscale poroelastic characterization of polymeric hydrogels via indentation. Soft Matter 8(12):3393–3398

Kloxin CJ, Bowman CN (2013) Covalent adaptable networks: smart, reconfigurable and responsive network systems. Chem Soc Rev 42(17):7161–7173

Le Tallec P, Rahier C, Kaiss A (1993) Three-dimensional incompressible viscoelasticity in large strains: formulation and numerical approximation. Comput Methods Appl Mech Eng 109(3–4):233–258

Leung S, Lowengrub J, Zhao H (2011) A grid based particle method for solving partial differential equations on evolving surfaces and modeling high order geometrical motion. J Comput Phys 230(7):2540–2561

Leung S, Zhao H (2009) A grid based particle method for moving interface problems. J Comput Phys 228(8):2993–3024

Lin DC, Yurke B, Langrana NA (2004) Mechanical properties of a reversible, DNA-crosslinked polyacrylamide hydrogel. J Biomech Eng 126(1):104–110

Lipson H, Kurman M (2013) Fabricated: the new world of 3D printing. Wiley, Hoboken

Liu X, Fernandes R, Jurisicova A, Casper RF, Sun Y (2010) In situ mechanical characterization of mouse oocytes using a cell holding device. Lab Chip 10(16):2154–2161

Liu X, Shi J, Zong Z, Wan K-T, Sun Y (2012) Elastic and viscoelastic characterization of mouse oocytes using micropipette indentation. Ann Biomed Eng 40(10):2122–2130

Long R, Hui C-Y (2010) Effects of triaxiality on the growth of crack-like cavities in soft incompressible elastic solids. Soft Matter 6(6):1238–1245

Lubliner J (1985) A model of rubber viscoelasticity. Mech Res Commun 12(2):93–99

Maeda T, Otsuka H, Takahara A (2009) Dynamic covalent polymers: reorganizable polymers with dynamic covalent bonds. Prog Polym Sci 34(7):581–604

Miehe C, Göktepe S, Lulei F (2004) A micro-macro approach to rubber-like materials. Part i: the non-affine micro-sphere model of rubber elasticity. J Mech Phys Solids 52(11):2617–2660

Miehe C, Göktepe S (2005) A micro-macro approach to rubber-like materials. Part ii: the micro-sphere model of finite rubber viscoelasticity. J Mech Phys Solids 53(10):2231–2258

Moës N, Béchet E, Tourbier M (2006) Imposing dirichlet boundary conditions in the extended finite element method. Int J Numer Methods Eng 67(12):1641–1669

Moës N, Belytschko T (2002) Extended finite element method for cohesive crack growth. Eng Fract Mech 69(7):813–833

Nanthakumar SS, Lahmer T, Zhuang X, Park HS, Rabczuk T (2016) Topology optimization of piezoelectric nanostructures. J Mech Phys Solids 94:316–335

Plohr BJ, Sharp DH (1988) A conservative Eulerian formulation of the equations for elastic flow. Adv Appl Math 9(4):481–499

Quadrini F, Squeo EA, Guglielmotti A (2010) Indentation creep of polymers. i. Experimental. Polym Eng Sci 50(12):2431–2439

Rasmussen HK (1999) Time-dependent finite-element method for the simulation of three-dimensional viscoelastic flow with integral models. J Non-Newton Fluid Mech 84(2–3):217–232

Reese S, Govindjee S (1998) A theory of finite viscoelasticity and numerical aspects. Int J Solids Struct 35(26–27):3455–3482

Shaw MT, MacKnight WJ (2005) Introduction to polymer viscoelasticity. Wiley, Hoboken

Shen T, Vernerey F (2017) Phoretic motion of soft vesicles and droplets: an XFEM/particle-based numerical solution. Comput Mech 60(1):143–161

Simo JC (1987) On a fully three-dimensional finite-strain viscoelastic damage model: formulation and computational aspects. Comput Methods Appl Mech Eng 60(2):153–173

Sridhar SL, Schneider MC, Chu S, de Roucy G, Bryant SJ, Vernerey FJ (2017) Heterogeneity is key to hydrogel-based cartilage tissue regeneration. Soft Matter 13(28):4841–4855

Stolarska M, Chopp DL, Moës N, Belytschko T (2001) Modelling crack growth by level sets in the extended finite element method. Int J Numer Methods Eng 51(8):943–960

Style RW, Boltyanskiy R, Allen B, Jensen KE, Foote HP, Wettlaufer JS, Dufresne ER (2014) Stiffening solids with liquid inclusions. arXiv preprint arXiv:1407.6424

Sukumar N, Chopp DL, Moës N, Belytschko T (2001) Modeling holes and inclusions by level sets in the extended finite-element method. Comput Methods Appl Mech Eng 190(46):6183–6200

Takashi N, Hughes TJR (1992) An arbitrary Lagrangian–Eulerian finite element method for interaction of fluid and a rigid body. Comput Methods Appl Mech Eng 95(1):115–138

Tanaka F, Edwards SF (1992) Viscoelastic properties of physically crosslinked networks. 1. Transient network theory. Macromolecules 25(5):1516–1523

Tezduyar TE, Behr M, Mittal S, Liou J (1992) A new strategy for finite element computations involving moving boundaries and interfaces the deforming-spatial-domain/space–time procedure: ii. Computation of free-surface flows, two-liquid flows, and flows with drifting cylinders. Comput Methods Appl Mech Eng 94(3):353–371

Treloar LRG (1943) The elasticity of a network of long-chain molecules ii. Trans Faraday Soc 39:241–246

Tvergaard V, Needleman A (2011) Polymer indentation: numerical analysis and comparison with a spherical cavity model. J Mech Phys Solids 59(9):1669–1684

Vernerey FJ (2018) Transient response of nonlinear polymer networks: a kinetic theory. J Mech Phys Solids 115:230–247

Vernerey FJ, Akalp U (2016) Role of catch bonds in actomyosin mechanics and cell mechanosensitivity. Phys Rev E 94(1):012403

Vernerey FJ, Farsad M (2011) A constrained mixture approach to mechano-sensing and force generation in contractile cells. J Mech Behav Biomed Mater 4(8):1683–1699

Vernerey FJ, Kabiri M (2012) An adaptive concurrent multiscale method for microstructured elastic solids. Comput Methods Appl Mech Eng 241:52–64

Vernerey FJ, Long R, Brighenti R (2017) A statistically-based continuum theory for polymers with transient networks. J Mech Phys Solids 107:1–20

Vitali E, Benson DJ (2006) An extended finite element formulation for contact in multi-material arbitrary Lagrangian–Eulerian calculations. Int J Numeric Methods Eng 67(10):1420–1444

Vu-Bac N, Bessa MA, Rabczuk T, Liu WK (2015) A multiscale model for the quasi-static thermo-plastic behavior of highly cross-linked glassy polymers. Macromolecules 48(18):6713–6723

Wojtecki RJ, Meador MA, Rowan SJ (2011) Using the dynamic bond to access macroscopically responsive structurally dynamic polymers. Nat Mater 10(1):14

Yamamoto M (1956) The visco-elastic properties of network structure i. General formalism. J Phys Soc Jpn 11(4):413–421

Zhu J, Li T, Cai S, Suo Z (2011) Snap-through expansion of a gas bubble in an elastomer. J Adhes 87(5):466–481

Zienkiewicz OC, Taylor RL, Zienkiewicz OC, Taylor RL (1977) The finite element method, vol 3. McGraw-Hill, London

Zimberlin JA, McManus JJ, Crosby AJ (2010) Cavitation rheology of the vitreous: mechanical properties of biological tissue. Soft Matter 6(15):3632–3635

Zimberlin JA, Sanabria-DeLong N, Tew GN, Crosby AJ (2007) Cavitation rheology for soft materials. Soft Matter 3(6):763–767

Acknowledgements

The author acknowledges the support of the National Science Foundation under the NSF CAREER award 1350090. Research reported in this publication was also partially supported by the National Institute of Arthritis and Musculoskeletal and Skin Diseases of the National Institutes of Health under Award Number 1R01AR065441. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institutes of Health.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: rate of change in stored elastic energy

To derive the rate of change in elastic energy, we first rewrite Eq. (7) as

where \(\varPsi = \frac{ck_BT}{2}tr(\varvec{\mu })\) and \(\varPsi _0 = \frac{ck_BT}{2}tr(\varvec{\mu }_0)\) are the stored elastic energy at the current and the stress-free state, respectively. Note that for bond exchange reaction, the change of chain concentration is only caused by the change in volume. Therefore, the third term on the right hand side can be equivalently written in terms of volume as \(p(\frac{V}{V_0}-1)\). The rate of change in the stored elastic energy is then written as

where \(tr(\mathbf {L})=\mathbf {I}:\mathbf {L}\) is the rate of change in volume. We first evaluate the term corresponding to the current state

We then employ the evolution equation (Eq. (4)) and the above equation becomes

Similarly, the term corresponding to the stress-free configuration in Eq. (38) can be obtained as

Combining Eqs. (38), (40) and (41), the rate of change in stored elastic energy reads

Appendix 2: field equations in cylindrical coordinates

In cylindrical coordinates, the balance of momentum equation can be written along the radial and the longitudinal direction as

The condition of incompressibility reads

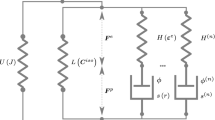

Appendix 3: discretization of element degrees of freedoms

In the numerical study, XFEM is implemented in the element shape functions to account for the discontinuities. For split elements, the shape function matrices \(\mathbf {N_v}\), \(\mathbf {N}_{\varvec{\mu }}\), \(\mathbf {N_p}\) and the vectors of element nodal values \(\mathbf {v}^e\) , \(\varvec{\mu }^e\), \(\mathbf {p}^e\) contain both standard and enriched DOFs and are defined as

where

and \( \mathbf {N_v}^I=\begin{bmatrix} N_9^I&0 \\ 0&N_9^I \end{bmatrix}. \)

Here, we note that \(\mathcal {S}^I=H(\phi (\mathbf {x})-H(\phi (\mathbf {x}^I))\). To compute the deformation rate of the material, velocity gradient tensor and the divergence of velocity are written as

The rate \(\mathbf {B_v}\) and \(\hat{\mathbf {B}}_\mathbf {v}\) matrices that are related to the nodal velocities to deformation rates are written in the cylindrical coordinates as

and

Appendix 4: element tangent matrix for governing equations

Using the equations of the evolution of the distribution tensor \(\varvec{\mu }\) (3), the components of the tangent matrix corresponding to the linear system (19) can be obtained as

and the element residual tensors

Here, we write the distribution tensor \(\varvec{\mu }=[\mu _{\rho \rho },\;\mu _{zz},\;\)\(\mu _{\rho z},\;\mu _{z\rho },\;\mu _{\theta \theta } ]\) in Voigt notation. Accordingly, \(\tilde{\varvec{\mu }}\) is the distribution tensor \(\varvec{\mu }\) written in the Mandel form and the components in \(\tilde{\varvec{\mu }}\) read

In the above equations, the variables with tilde superscript \(\tilde{(.)}\) indicate that they are interpolated using the fields from the previous timestep. We note that in many problems, the values of boundary traction \(\overline{\varvec{t}}\) and body force \(\mathbf {b}\) are usually given instead of their time derivatives \(\dot{\overline{\varvec{t}}}\) and \(\dot{\mathbf {b}}\). In this case, a forward difference scheme is used for the time derivatives. For example, at time step n

Appendix 5: evolution of the interface

As discussed in the text, the interface is characterized and tracked using the PMIM algorithm with the following steps:

(a) Interface initialization At the initial time \(t_0\), the interface is discretized by the particles, whose position vector \(\mathbf {y}\) are chosen as the closest points from each neighboring grid nodes to the interface. The position vector \(\mathbf {y}\) can be obtained using our knowledge of initial levelset function \(\phi (\mathbf {x}, t_0)\) as

where the normal vector is obtained by \(\bar{\mathbf {n}}=\nabla \phi (\mathbf {x}, t_0)\) [27] and \(\mathbf {x}\) is the position vector of the corresponding grid node.

(b) Update the interface At an arbitrary time t, given the velocity solution of the interface velocity \(\bar{\mathbf {v}}^t\), update the position of each particle by a second order Runge-Kutta scheme as

where \(\varvec{\varOmega }\) is the skew-symmetric spin tensor that reads

The function is then updated to account for the new geometry of the interface

where \(g(\mathbf {y}^{t+dt},\;\mathbf {x})\) is a sign function that determines whether a point \(\mathbf {x}\) locates inside or outside of the interface

It is clear that the function g takes the value \(-\,1\) inside the vesicle, and 1 outside the vesicle.

(c) Interface approximation After obtaining the updated levelset function, the interface geometry is approximated using the local polynomials for each particle P. More specifically, for each particle P with position vector \(\mathbf {y}_p\), one can introduce a local orthonormal basis that consists of tangent and normal vectors \(\{\bar{\mathbf {a}}^{t+dt}_p, \bar{\mathbf {n}}^{t+dt}_p\}\) to the interface. These two quantities can be obtained from the levelset function as follows

where \(\mathbf {m}=[0\;0\;1]^T\) is the unit vector normal to the computational domain. To approximate the local geometry of the interface, we collect the closest m particles in the neighborhood of P, given by their positions \(\tilde{\mathbf {y}}_1\dots \tilde{\mathbf {y}}_m\) in the local coordinates

and construct a polynomial using the least square fitting method

where the coefficients \(c_i\) are determined by minimizing the \(L^2\) difference between the approximation \(\xi ^2(\xi _i^1)\) and the nodal values \(\xi _i^2\). In this way, a local parameterization \(\mathbf {r}^l(\rho ,\;t)\) of the interface around the particle \(\mathbf {y}_p\) is achieved, whose global parameterization \(\mathbf {r}(\rho ,\;t)\) can then be obtained as

Finally, the tangential and normal vectors for a point on the interface \(\varGamma \) can be obtained in the global coordinates as

Appendix 6: element matrices for enriched degrees of freedom

The global tangent matrices to compute the enriched degrees of freedom \(\overline{\varvec{\mu }}^{enr}_g\) and \(\overline{\mathbf {p}}^{enr}_g\) are written as

and the residue vector is given by

In the above equations \(\sum _e\) indicates the matrix assembly of the global system from the element matrices.

Rights and permissions

About this article

Cite this article

Shen, T., Long, R. & Vernerey, F. Computational modeling of the large deformation and flow of viscoelastic polymers. Comput Mech 63, 725–745 (2019). https://doi.org/10.1007/s00466-018-1619-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-018-1619-0