Abstract

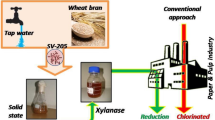

To reduce pollution and cost of treatment for fresh and recycled paper, co-production of xylanase and laccase was carried out in the same production medium using two compatible species of Bacillus. These co-produced enzymes were used for deinking of old newsprint (ONP) and biobleaching of eucalyptus Kraft pulp. Solid-state co-cultivation of Bacillus sp. and B. halodurans FNP135 was optimized statistically by response surface methodology for the co-production of xylanase (X) and laccase (L). A significant increase in production of xylanase (2.1-fold, 1,685 IU/g) and laccase (2.04-fold, 2,270 nkat/g) was observed under optimized conditions viz. pH (10.5), inoculum size (10 + 10 %) and moisture:substrate ratio (0.8:1). Both the enzymes showed identical temperature and pH optima of 70 °C and 9, respectively, and were used for deinking of ONP pulp and biobleaching of kraft pulp. In case of ONP pulp deinking, the XL treatment increased brightness (11.8 %), freeness (17.8 %), breaking length (34.8 %), burst factor (2.77 %) and tear factor (2.4 %). In case of kraft pulp biobleaching, XL treatment showed a significant increase in brightness (13 %), whiteness (106.15 %) breaking length (49 %), burst factor (6.9 %), tear factor (23 %), and viscosity (11.68 %) and reduction in kappa number (15 %) after alkali extraction and peroxide stage. This enhancement of pulp properties revealed a synergistic effect of xylanase and laccase produced in one setup.

Similar content being viewed by others

References

Dhiman SS, Garg G, Sharma J, Kalia VC, Kang YC, Lee JK (2014) Reduction in acute ecotoxicity of paper mill effluent by sequential application of xylanase and laccase. PLoS One 9:1–13

Chandra R, Singh R (2012) Decolourisation and detoxification of rayon grade pulp paper mill effluent by mixed bacterial culture isolated from pulp paper mill effluent polluted site. Biochem Eng J 61:49–58

Fillat U, Roncero MB (2009) Biobleaching of high quality pulps with laccase mediator system: influence of treatment time and oxygen supply. Biochem Eng J 44:193–198

Valls C, Vidal T, Roncero MB (2010) Boosting the effect of a laccase-mediator system by using a xylanase stage in pulp bleaching. J Hazard Mater 177:586–592

Virk AP, Puri M, Gupta V, Capalash N, Sharma P (2013) Combined enzymatic and physical deinking methodology for efficient eco-friendly recycling of old newsprint. PLoS One 8:1–8

Kunamneni A, Ballesteros A, Plou FJ, Alcalde M (2007) Fungal laccase—a versatile enzyme for biotechnological applications. Comm Curr Res Educ Top Trends Appl Microbiol 233–245

Tripathi A, Upadhyay RC, Singh S (2012) Extracellular Ligninolytic Enzymes in Bjerkandera adusta and Lentinus squarrosulus. Indian J Microbiol 52:381–387

Sarria-Alfonso V, Sanchez-Sierra J, Aguirre-Morales M, Gutie´rrez-Rojas I, Moreno-Sarmiento N, Poutou-Pinales R (2013) Culture media statistical optimization for biomass production of a ligninolytic fungus for future rice straw degradation. Indian J Microbiol 52:199–207

Patel SKS, Kalia VC, Choi JH, Haw JR, Kim IW, Lee JK (2014) Immobilization of laccase on SiO2 nanocarriers improves its stability and reusability. J Microbiol Biotechnol 24:639–647

Valls C, Roncero MB (2009) Using both xylanase and laccase enzymes for pulp bleaching. Bioresour Technol 100:2032–2039

Kapoor M, Kapoor RK, Kuhad RC (2007) Differential and synergistic effects of xylanase and laccase mediator system (LMS) in bleaching of soda and waste pulps. J Appl Microbiol 103:305–317

Vinogradova SP, Kushnir SN (2008) Biosynthesis of hydrolytic enzymes during cocultivation of macro- and micromycetes. Prikl Biokhim Mikrobiol 39:652–655

Dwivedi P, Vivekanand V, Pareek N, Sharma A, Singh RP (2011) Co-cultivation of mutant Penicillium oxalicum SAUE-3.510 and Pleurotus ostreatus for simultaneous biosynthesis of xylanase and laccase under solid-state fermentation. N Biotechnol 28:616–626

Gutierrez-Correa M, Tengerdy RP (1997) Production of cellulase on sugar cane bagasse by fungal mixed culture solid substrate fermentation. Biotechnol Lett 19:665–667

Kaushal R, Sharma N, Tandon D (2012) Cellulase and xylanase production by co-culture of Aspergillus niger and Fusarium oxysporum utilizing forest waste. Turk J Biochem 37:35–41

Woldesenbet F, Gupta N, Sharma P (2012) Statistical optimization of the production of a cellulase-free, thermo- alkali-stable, salt- and solvent-tolerant xylanase from Bacillus halodurans by solid state fermentation. Archiv Appl Sci Res 4:524–535

Ikura Y, Horikoshi K (1987) Stimulatory effect of certain amino acids on xylanase production by alkalophilic Bacillus sp. Agric Biol Chem 51:3143–3145

Degryse E, Glandsdorff N, Picrard A (1978) A comparative analysis of extreme thermophilic bacteria belonging to the genus Thermus. Arch Microbiol 117:189–196

Bailey MR, Woodard SL, Callaway E, Beifuss K, Magallanes-Lundback M, Lane JR, Hood EE (2004) Improved recovery of active recombinant laccase from maize seed. Appl Microbiol Biotechnol 63:390–397

Bains J, Capalash N, Sharma P (2003) Laccase from a non-melanogenic, alkalotolerant γ -proteobacterium JB isolated from industrial wastewater drained soil. Biotechnol Lett 25:1155–1159

Mohana S, Shah A, Divecha J, Madamwar D (2008) Xylanase production by Burkholderia sp. DMAX strain under solid state fermentation using distillery spent wash. Bioresour Technol 99:7553–7564

Malhotra K, Sharma P, Capalash N (2004) Copper and dyes enhance laccase production in γ-proteobacterium JB. Biotechnol Lett 26:1047–1050

Tavares APM, Coelho MAZ, Coutinho JAP, Xavier AMRB (2005) Laccase improvement in submerged cultivation: induced production and kinetic modelling. J Chem Technol Biotechnol 80:669–676

Mansur M, Suárez T, Fernández-Larrea JB, Brizuela M, González E (1997) Identification of a laccase gene family in the new lignin-degrading basidiomycete CECT 20197. Appl Environ Microbiol 63:2637–2646

Vasconcelos AFD, Barbosa AN, Dekker RFH, Scarminio IS, Rezende MI (2000) Optimisation of laccase production by Botryosphaeria sp in the presence of veratryl alcohol by the response-surface method. Process Biochem 35:1131–1138

Xavier AMRB, Tavares APM, Ferreira R, Amado F (2007) Trametes versicolor growth and laccase induction with by-products of pulp and paper industry. Electron J Biotechnol 10:443–451

Sanghi A, Garg N, Kuhar K, Kuhad RC, Gupta VK (2009) Enhanced production of cellulase-free xylanase by alkalophilic Bacillus subtilis ASH and its application in biobleaching of kraft pulp. Bioresources 4:1109–1129

Archana A, Satyanarayana T (1997) Xylanase production by thermophilic Bacillus licheniformis A99 in solid-state fermentation. Enzym Microb Technol 21:12–17

Battan B, Sharma EJ (2006) High-level xylanase production by alkaliphilic Bacillus pumilus ASH under solid-state fermentation. World J Microbiol Biotechnol 22:1281–1287

Niladevi KN, Sukumaran RK, Jacob N, Anisha GS, Prema PA (2009) Optimization of laccase production from a novel strain—Streptomyces psammoticus using response surface methodology. Microbiol Res 164:105–113

Liu J, Hu H, Xu J, Wen Y (2012) Optimizing enzymatic pretreatment of recycled fiber to improve its draining ability using response surface methodology. Bioresources 7:2121–2140

Bourbonnais R, Paice MG, Freiermuth B, Bodie E, Borneman S (1997) Reactivities of various mediators and laccase with kraft pulp and lignin model compounds. Appl Environ Microbiol 63:4627–4632

Thakur VV, Jain RK, Mathur RM (2012) Studies on xylanase and laccase enzymatic prebleaching to reduce chlorine-based chemicals during CEH and ECF bleaching. Bioresources 7:2220–2235

Dwivedi P, Vivekanand V, Pareek N, Sharma A, Singh RP (2010) Bleach enhancement of mixed wood pulp by xylanase-laccase concoction derived through co-culture strategy. Appl Biochem Biotechnol 160:255–268

Acknowledgments

This work was supported by Department of Biotechnology, Government of India, New Delhi (Grant No. BT/PR11384/GBD/27/157/2008). University Grants Commission, New Delhi, is gratefully acknowledged for providing junior research fellowship to V. Gupta. The authors are thankful to Dr. Narender Sharma and Mr. R. P. Singh, Kuantum Paper Mills, Punjab, India for providing facilities and support for carrying out the bleaching and deinking experiments at their paper mill.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gupta, V., Garg, S., Capalash, N. et al. Production of thermo-alkali-stable laccase and xylanase by co-culturing of Bacillus sp. and B. halodurans for biobleaching of kraft pulp and deinking of waste paper. Bioprocess Biosyst Eng 38, 947–956 (2015). https://doi.org/10.1007/s00449-014-1340-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1340-0