Abstract

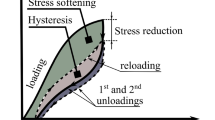

The damage and aging of short fiber-reinforced rubber composites (SFRCs) have a significant impact on the performance and stability of associated products. However, the presence of internal short fibers and the large deformation characteristics of rubber materials make it difficult to characterize the damage behavior. Therefore, it is imperative to investigate the material’s damage behavior, as well as the influence of aging on mechanical properties, and develop a precise constitutive model. This study extends configurational mechanics to hyperelastic materials and introduces the concept of equivalent configurational stress as a physically meaningful variable representing damage, thereby establishing a constitutive model that couples aging and damage. Uniaxial tensile tests were performed on samples in various aging states to analyze the damage behavior of SFRCs and validate the accuracy of the proposed constitutive model. Furthermore, this research highlights the prospective application of configuration mechanics in characterizing damage in composite materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Data availability

No datasets were generated or analyzed during the current study.

References

Goettler, L., Shen, K.: Short fiber reinforced elastomers. Rubber Chem. Technol. 56(3), 619–638 (1983). https://doi.org/10.5254/1.3538144

Abrate, S.: The mechanics of short fiber-reinforced composites: a review. Rubber Chem. Technol. 59(3), 384–404 (1986)

Kashani, M.R.: Aramid-short-fiber reinforced rubber as a tire tread composite. J. Appl. Polym. Sci. 113(2), 1355–1363 (2009). https://doi.org/10.1002/app.30026

Jayan, J.S., Appukuttan, S., Wilson, R., Joseph, K., George, G., Oksman, K.: 1 - an introduction to fiber reinforced composite materials. In: Joseph, K., Oksman, K., George, G., Wilson, R., Appukuttan, S. (eds.) Fiber Reinforced Composites. Woodhead Publishing Series in Composites Science and Engineering, pp. 1–24. Woodhead Publishing, England (2021). https://doi.org/10.1016/B978-0-12-821090-1.00025-9

Patel, M., Soames, M., Skinner, A.R., Stephens, T.S.: Stress relaxation and thermogravimetric studies on room temperature vulcanised polysiloxane rubbers. Polym. Degrad. Stab. 83(1), 111–116 (2004). https://doi.org/10.1016/S0141-3910(03)00231-3

Gillen, K.T., Celina, M.: Predicting polymer degradation and mechanical property changes for combined radiation-thermal aging environments. Rubber Chem. Technol. 91(1), 27–63 (2018). https://doi.org/10.5254/rct.18.81679

Celina, M., Linde, E., Brunson, D., Quintana, A., Giron, N.: Overview of accelerated aging and polymer degradation kinetics for combined radiation-thermal environments. Polym. Degrad. Stab. 166, 353–378 (2019). https://doi.org/10.1016/j.polymdegradstab.2019.06.007

Pan, Y., Zhong, Z.: Modeling the mullins effect of rubber-like materials. Int. J. Damage Mech 26(6), 933–948 (2017). https://doi.org/10.1177/1056789516635728

Yang, Y., Zhou, Q., Deng, Y., Lin, J.: Compressive behaviors of ultra-low-weight foamed cement-based composite reinforced by polypropylene short fibers. Int. J. Damage Mech. 29(8), 1306–1325 (2020). https://doi.org/10.1177/1056789520908638

Grandcoin, J., Boukamel, A., Lejeunes, S.: A micro-mechanically based continuum damage model for fatigue life prediction of filled rubbers. Int. J. Solids Struct. 51(6), 1274–1286 (2014). https://doi.org/10.1016/j.ijsolstr.2013.12.018

Tan, K.T., Watanabe, N., Iwahori, Y.: Impact damage resistance, response, and mechanisms of laminated composites reinforced by through-thickness stitching. Int. J. Damage Mech. 21(1), 51–80 (2012). https://doi.org/10.1177/1056789510397070

Garcea, S., Sinclair, I., Spearing, S., Withers, P.: Mapping fibre failure in situ in carbon fibre reinforced polymers by fast synchrotron x-ray computed tomography. Compos. Sci. Technol. 149, 81–89 (2017). https://doi.org/10.1016/j.compscitech.2017.06.006

Zhang, B., Yu, X., Gu, B.: Modeling and experimental validation of interfacial fatigue damage in fiber-reinforced rubber composites. Polym. Eng. Sci. 58(6), 920–927 (2018). https://doi.org/10.1002/pen.24646

Liu, R., Sancaktar, E.: Identification of crack progression in filled rubber by micro x-ray ct-scan. Int. J. Fatigue 111, 144–150 (2018). https://doi.org/10.1016/j.ijfatigue.2018.01.033

Matsubara, M., Teramoto, S., Nagatani, A., Kawamura, S., Tsujiuchi, N., Ito, A., Kobayashi, M., Furuta, S.: Effect of fiber orientation on nonlinear damping and internal microdeformation in short-fiber-reinforced natural rubber. Exp. Tech. 45, 37–47 (2021). https://doi.org/10.1007/s40799-020-00404-6

Akhtar, S., De, P., De, S.: Short fiber-reinforced thermoplastic elastomers from blends of natural rubber and polyethylene. J. Appl. Polym. Sci. 32(5), 5123–5146 (1986). https://doi.org/10.1002/app.1986.070320530

Nguyen, B.N., Khaleel, M.A.: - prediction of damage in a randomly oriented short-fiber composite plate containing a central hole1. In: Bathe, K.J. (ed.) Computational Fluid and Solid Mechanics 2003, pp. 519–522. Elsevier Science Ltd, Oxford (2003). https://doi.org/10.1016/B978-008044046-0.50128-7

Nguyen, B.N., Tucker, B.J., Khaleel, M.A.: A mechanistic approach to matrix cracking coupled with fiber-matrix debonding in short-fiber composites. J. Eng. Mater. Technol. 127(3), 337–350 (2005). https://doi.org/10.1115/1.1924565

Al-Rub, R.K.A., Tehrani, A.H., Darabi, M.K.: Application of a large deformation nonlinear-viscoelastic viscoplastic viscodamage constitutive model to polymers and their composites. Int. J. Damage Mech 24(2), 198–244 (2015). https://doi.org/10.1177/1056789514527020

Li, Q., Chen, Y.: Surface effect and size dependence on the energy release due to a nanosized hole expansion in plane elastic materials. J. Appl. Mech. 75(6), 061008 (2008). https://doi.org/10.1115/1.2965368

Hu, Y., Li, Q., Shi, J., Chen, Y.: Surface/interface effect and size/configuration dependence on the energy release in nanoporous membrane. J. Appl. Phys. 112(3), 034302 (2012). https://doi.org/10.1063/1.4740224

Li, Q., Lv, J., Guo, Y., Tian, X.: A consistent framework of material configurational mechanics in piezoelectric materials. Acta Mech. 229(1), 299–322 (2018). https://doi.org/10.1007/s00707-017-1966-5

Yuan, Z., Li, Q.: A configurational force based anisotropic damage model for original isotropic materials. Eng. Fract. Mech. 215, 49–64 (2019). https://doi.org/10.1016/j.engfracmech.2019.04.029

Wang, R., Yuan, Z., Li, Q., Yang, B., Zuo, H.: Damage evolution of biodegradable magnesium alloy stent based on configurational forces. J. Biomech. 122, 110443 (2021). https://doi.org/10.1016/j.jbiomech.2021.110443

Ishak, Z.M., Berry, J.: Hygrothermal aging studies of short carbon fiber reinforced nylon 6.6. J. Appl. Polym. Sci. 51(13), 2145–2155 (1994). https://doi.org/10.1002/app.1994.070511306

Bradshaw, R., Brinson, L.: Physical aging in polymers and polymer composites: An analysis and method for time-aging time superposition. Polym. Eng. Sci. 37(1), 31–44 (1997). https://doi.org/10.1002/pen.11643

Ishak, Z.M., Ishiaku, U., Karger-Kocsis, J.: Hygrothermal aging and fracture behavior of short-glass-fiber-reinforced rubber-toughened poly (butylene terephthalate) composites. Compos. Sci. Technol. 60(6), 803–815 (2000). https://doi.org/10.1016/S0266-3538(99)00193-1

Sethi, S., Ray, B.C.: Environmental effects on fibre reinforced polymeric composites: Evolving reasons and remarks on interfacial strength and stability. Adv. Coll. Interface. Sci. 217, 43–67 (2015). https://doi.org/10.1016/j.cis.2014.12.005

Zheng, T., Zheng, X., Zhan, S., Zhou, J., Liao, S.: Study on the ozone aging mechanism of natural rubber. Polym. Degrad. Stab. 186, 109514 (2021). https://doi.org/10.1016/j.polymdegradstab.2021.109514

Lv, J., Li, Q.: Equivalent configurational stress to predict material yielding and crack propagation. Acta Mech. 227, 3055–3065 (2016). https://doi.org/10.1007/s00707-016-1665-7

Eshelby, J.D., Frank, F.C., Nabarro, F.R.: Xli. the equilibrium of linear arrays of dislocations. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science 42(327), 351–364 (1951). https://doi.org/10.1080/14786445108561060

Kienzler, R., Herrmann, G.: On the properties of the Eshelly tensor. Acta Mech. 125(1–4), 73–91 (1997). https://doi.org/10.1007/BF01177300

Eischen, J., Herrmann, G.: Energy release rates and related balance laws in linear elastic defect mechanics. J. Appl. Mech. 54(2), 388–392 (1987). https://doi.org/10.1115/1.3173024

Marino, M., Wriggers, P.: Nearly-constrained transversely isotropic linear elasticity: energetically consistent anisotropic deformation modes for mixed finite element formulations. Int. J. Solids Struct. 202, 166–183 (2020). https://doi.org/10.1016/j.ijsolstr.2020.05.011

Mo, C., Jiang, Y., Raney, J.R.: Microstructural evolution and failure in short fiber soft composites: experiments and modeling. J. Mech. Phys. Solids 141, 103973 (2020). https://doi.org/10.1016/j.jmps.2020.103973

Ghassemieh, E., Nassehi, V.: Stiffness analysis of polymeric composites using the finite element method. Adv. Polym. Technol. 20(1), 42–57 (2001)

Holzapfel, G.A.: Nonlinear solid mechanics: a continuum approach for engineering science. Kluwer Academic Publishers Dordrecht (2002)

Khajehsaeid, H., Arghavani, J., Naghdabadi, R.: A hyperelastic constitutive model for rubber-like materials. Eur. J. Mech. -A/Solids 38, 144–151 (2013). https://doi.org/10.1016/j.euromechsol.2012.09.010

Mansouri, M., Darijani, H.: Constitutive modeling of isotropic hyperelastic materials in an exponential framework using a self-contained approach. Int. J. Solids Struct. 51(25–26), 4316–4326 (2014). https://doi.org/10.1016/j.ijsolstr.2014.08.018

Chen, S., Wang, C., Lu, X., Li, M., Li, M., Li, Q.: A parameter identification scheme of the visco-hyperelastic constitutive model of rubber-like materials based on general regression neural network. Archive Appl. Mech. (2023). https://doi.org/10.1007/s00419-023-02434-z

Deuri, A.S., Bhowmick, A.K.: Aging of EPDM rubber. J. Appl. Polym. Sci. 34(6), 2205–2222 (1987). https://doi.org/10.1002/app.1987.070340613

Wang, X., Yang, K., Zhang, P.: Evaluation of the aging coefficient and the aging lifetime of carbon black-filled styrene-isoprene-butadiene rubber after thermal-oxidative aging. Compos. Sci. Technol. 220, 109258 (2022). https://doi.org/10.1016/j.compscitech.2021.109258

Liu, J., Li, X., Xu, L., Zhang, P.: Investigation of aging behavior and mechanism of nitrile-butadiene rubber (NBR) in the accelerated thermal aging environment. Polym. Testing 54, 59–66 (2016). https://doi.org/10.1016/j.polymertesting.2016.06.010

Li, Y., Liu, X., Hu, X., Luo, W.: Changes in tensile and tearing fracture properties of carbon-black filled rubber vulcanizates by thermal aging. Polym. Adv. Technol. 26(11), 1331–1335 (2015). https://doi.org/10.1002/pat.3683

Wang, S., Xu, J., Li, H., Liu, J., Zhou, C.: The effect of thermal aging on the mechanical properties of ethylene propylene diene monomer charge coating. Mech. Time-Depend. Mater. 28(2), 321–336 (2024). https://doi.org/10.1007/s11043-022-09557-w

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos.12172270), the Fundamental Research Funds for the Central Universities in China. The author Qun Li gratefully acknowledges the support of K.C. Wong Education Foundation.

Author information

Authors and Affiliations

Contributions

Chen wrote the main manuscript text, Chen and Li completed the theoretical derivation, Chen and Wang carried out the experimental work. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, S., Wang, C. & Li, Q. A phenomenological aging-damage hyperelastic model based on configurational mechanics for short fiber-reinforced rubber composites. Arch Appl Mech 95, 33 (2025). https://doi.org/10.1007/s00419-024-02746-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00419-024-02746-8