Abstract

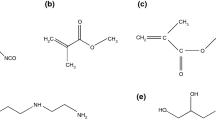

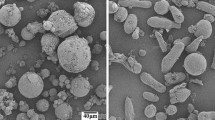

Microcapsules containing phase change materials (microPCMs) with melamine-formaldehyde (MF) shells have been applied in many thermo-regulation or thermo-saving fields. However, it is still essential to decrease the residual formaldehyde and enhance the mechanical properties of MF shells. The objective of this work was to fabricate a series of microPCMs containing paraffin by an in situ polymerization method using methanol-modified melamine-formaldehyde (MMF) prepolymer as shell material and investigate the physicochemical properties and mechanical characters of these microPCMs. FT-IR analysis indicates that the methanol-modified method can reduce the free formaldehyde in shell material through increasing the cross-linking structure. Optical microphotographs and SEM morphologies show that the microPCMs have regular globe shape with smooth surface. With the increasing of emulsion stirring rates from 1,000 to 5,000 rpm, the average diameters decreased sharply from 27 to 2.5 μm. The phase change temperature (T m) of microPCMs samples with the core/shell ratios of 3/1, 2/1, 1/1, and 2/1 are 22.6, 23.0, 23.4, and 23.9 °C, which are nearly equaled to the T m of pure paraffin (22.5 °C). Mechanical properties test data show that the MMF shells have larger yield point value than that of MF shell for microPCMs with the same core/shell ratio, which means that the methanol-modified method shell can greatly enhanced the resistance of deformation for MF shells. Moreover, MMF shells can resist the interface extrusion force in epoxy resin owing to their higher yield point of enhanced MMF shell.

Similar content being viewed by others

References

Zhang YP, Hu XX, Wang X (2003) Theoretical analysis of convective heat transfer enhancement of microencapsulated phase change material slurries. Heat Mass Transf 40:59–66

Zhang XX, Tao XM, Yick KL, Fan YF (2005) Expansion space and thermal stability of microencapsulated n-octadecane. J Appl Polym Sci 97:390–396

Su JF, Wang LX, Ren L (2005) Preparation and characterization of double-mf shell microPCMs used in building materials. J Appl Polym Sci 97:1755–1762

Kwon JY, Kim HD (2006) Preparation and application of polyurethane-urea microcapsules containing phase change materials. Fiber Polym 7:12–19

Roy SK, Avanic BL (1997) Laminar forced convection heat transfer with phase change material emulsions. Int Commun Heat Mass Transf 24:653–662

Yang R, Xu H, Zhang YP (2003) Preparation, physical property and thermal physical property of phase change microcapsule slurry and phase change emulsion. Sol Energy Mater Sol Cells 80:405–416

Su JF, Ren L, Wang LX (2005) Preparation and mechanical properties of thermal energy storage microcapsules. Colloid Polym Sci 284:224–228

Zhao ZN, Hao R, Shi YQ (2008) Parametric analysis of enhanced heat transfer for laminar flow of microencapsulated phase change suspension in a circular tube with constant wall temperature. Heat Transfer Eng 29:97–106

Su JF, Wang LX, Ren L (2006) Fabrication and thermal properties of microPCMs: used melamine-formaldehyde resin as shell material. J Appl Polym Sci 101:1522–1528

Choi JK, Lee JG, Kim JH, Yang HS (2001) Preparation of microcapsules containing phase change materials as heat transfer media by in-situ polymerization. J Ind Eng Chem 7:358–362

Fallahi E, Barmar M, Kish MH (2010) Preparation of phase-change material microcapsules with paraffin or camel fat cores: application to fabrics. Iran Polym J 19:277–286

Yu F, Chen ZH, Zeng XR (2009) Preparation, characterization, and thermal properties of microPCMs containing n-dodecanol by using different types of styrene-maleic anhydride as emulsifier. Colloid Polym Sci 287:549–560

Liu GM, Xie BQ, Fu DS, Wang Y, Fu Q, Wang DJ (2009) Preparation of nearly monodisperse microcapsules with controlled morphology by in-situ polymerization of a shell layer. J Mater Chem 19:6605–6609

Gao GB, Qian CX, Gao MJ (2010) Preparation and characterization of hexadecane microcapsule with polyurea-melamine formaldehyde resin shell materials. Chin Chem Lett 21:533–537

Li W, Zhang XX, Wang XC, Niu JJ (2007) Preparation and characterization of microencapsulated phase change material with low remnant formaldehyde content. Mater Chem Phys 106:437–442

Wang RG, Li HY, Hu HL, He XD, Liu WB (2009) Preparation and characterization of self-healing microcapsules with poly (urea-formaldehyde) grafted epoxy functional group shell. J Appl Polym Sci 113:1501–1506

Fery A, Weinkamer R (2007) Mechanical properties of micro- and nanocapsules: single-capsule measurements. Polymer 48:7221–7235

Hua JF, Chen HQ, Zhang ZB (2009) Mechanical properties of melamine formaldehyde microcapsules for self-healing materials. Mater Chem Phys 118:63–70

Su JF, Huang Z, Ren L (2007) High compact melamine-formaldehyde microPCMs containing n-octadecane fabricated by a two-step coacervation method. Colloid Polym Sci 285:1581–1591

Su JF, Wang LX, Ren L (2007) Synthesis of polyurethane microPCMs containing n-octadecane by interfacial polycondensation: influence of styrene-maleic anhydride as a surfactant. Colloids Surf A 299:268–275

Su JF, Wang LX, Ren L, Zhen H (2007) Mechanical properties and thermal stability of double-shell thermal energy storage microcapsules. J Appl Polym Sci 103:1295–1302

Sun G, Zhang Z (2002) Mechanical strength of microcapsules made of different wall materials. Int J Pharm 242:307–311

Lee HY, Lee SJ, Cheong W, Kim JH (2002) Microencapsulation of fragrant oil via in situ polymerisation: effects of pH and melamine-formaldehyde molar ratio. J Microencapsul 19:559–569

Acknowledgments

The authors are grateful to the financial support of the National Natural Science Foundation of China (No. 50803045).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, JF., Wang, SB., Zhang, YY. et al. Physicochemical properties and mechanical characters of methanol-modified melamine-formaldehyde (MMF) shell microPCMs containing paraffin. Colloid Polym Sci 289, 111–119 (2011). https://doi.org/10.1007/s00396-010-2328-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-010-2328-1