Abstract

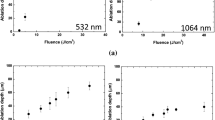

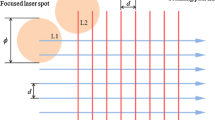

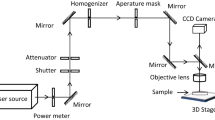

In this work, the ablation rate and surface modifications are studied of aluminum nitride ceramic treated by a pulsed nanosecond Nd:YAG laser at four wavelengths—266 nm, 355 nm, 532 nm, and 1064 nm. The ablation depth is presented as a function of the laser fluence and the number of pulses applied. A decrease of the ablation efficiency with the increase of both laser fluence and number of pulses is observed for all wavelengths used. It is found that the laser treatment leads to the formation of a variety of micro and nanostructures on the surface of the material that are strongly dependent on the processing conditions. The laser ablation at the fundamental wavelength leads to the appearance of periodic structures on the surface. Such effect is not observed for the other wavelengths used. It is further found that the laser processing also leads to the formation a conductive layer for all wavelengths. Using a model based on the heat diffusion equation that takes into account the process of ceramic decomposition, the ablation dynamics is followed, and the dependence of the surface layers thickness on the processing conditions is estimated. The results obtained are used to explain the experimentally observed dependences.

Similar content being viewed by others

References

D.H.A. Besisaac, E.M.M. Ewais, Y.M.Z. Ahmed, F.I. Elhosiny, D.V. Kuznetsov, T. Fen, Ren. Energy A 129, 201 (2018)

M. Ma, Y. Wang, M. Navarro-Cía, F. Liu, F. Zhang, Z. Liu, Y. Li, S.M. Hanham, Z. Hao, J. Eur. Ceram. Soc. 39, 4424 (2019)

G. Guisbiers, L. Buchaillot, J. Phys. D: Appl. Phys. 41, 172001 (2008)

V. Onbattuvelli, S. Atre, Mater. Manufact. Proc. 26, 832 (2011)

Z. Valdez-Nava, D. Kenfaui, M. -L. Locatelli, L. Laudebat and S. Guillemet, In: 2019 IEEE Intern. Workshop Integr. Power Packaging (IWIPP), 91 (2019), https://doi.org/10.1109/IWIPP.2019.8799084

A.N. Samant, N.B. Dahotre, J. Europ. Ceram. Soc. 29, 969 (2009)

Q. Yang, Y. Chen, Zh. Liv, L. Chen, D. Lou, Zh. Zheng, J. Cheng, D. Liu, J. Mater. Sci. 54, 13874 (2019)

P.A.M. Aguilar, M. Vlasova, M. Kakazey, D.M. Cruz, E.J. Arellano, V. Stetsenko, T. Tomila, A. Ragulya, Opt. Laser Technol. 42, 172 (2010)

P.E. Koziol, A.J. Antonczak, P. Szymczyk, B. Stepak, K.M. Abramski, Appl. Surf. Sci. 287, 165 (2013)

B. Stolz, R. Poprawe, Surf. Coat. Technol. 112, 394 (1999)

S. Cao, A.J. Pedraza, L.F. Allard, J. Mater. Res. 10, 54 (1995)

Y. Hirayama, H. Yabe, M. Obara, J. Appl. Phys. 89, 2943 (2001)

S.H. Kim, I.-B. Sohn, S. Jeong, Appl. Surf. Sci. 255, 9717 (2009)

C. Dowding in Advances in Laser Materials Processing, Woodhead Publishing ISBN 978-1-84569-981-9

J. Bonse, S. Hohm, S.V. Kirner, A. Rosenfeld, J. Kruger, IEEE Quant. Electr. 23, 9000615 (2017)

N.N. Nedyalkov, A. Dikovska, R. Nikov, G. Atanasova, S. Hayashi, M. Terakawa, Opt. Las. Technol. 144, 107402 (2021)

N.M. Shaikh, S. Hafeez, B. Rashid, M.A. Baig, Eur. Phys. J. D 44, 371 (2007)

P. Sainz de Baranda, A.K. Knudsen, M.E. Pruitt, E. Ruh, J. Am. Chem. Soc. 77, 1846 (1994)

V.I. Konov, F. Dausinger, S.V. Garnov, S.M. Klimentov, T.V. Kononenko, O.G. Tzarkova, In: Proc. SPIE 2991, 151 (1997)

M. Leitner, T. Leitner, A. Schmon, K. Aziz, G. Pottlacher, Metallurg. Mater. Transact. A 48, 3036 (2017)

O. Varlamova, C. Martens, M. Ratzke, J. Reif, Appl. Opt. 53, 10 (2014)

Y. Nakajima, N. Nedyalkov, A. Takami, M. Terakawa, Appl. Phys. A (2015). https://doi.org/10.1007/s00339-015-9166-4

M. Dasbach, H.M. Reinhardt, N.A. Hampp, Nanomaterials 9, 1031 (2019). https://doi.org/10.3390/nano9071031

Acknowledgements

This work was supported by Bulgarian Science Fund under project KP-06-H47/11

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Data availability

All data generated or analyzed during this study are included in this published article or is available upon request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nedyalkov, N., Dikovska, A., Aleksandrov, L. et al. Nanosecond laser ablation of AlN ceramic. Appl. Phys. A 127, 951 (2021). https://doi.org/10.1007/s00339-021-05106-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-05106-3