Abstract

An experimental investigation on the porous bronze at various strain rates is firstly carried out in this study to explore the effects of relative density and strain rate in the mechanical behavior. Furthermore, a multi-parameter constitutive model of describing the rate-dependent behavior for porous bronze is developed. The parameters in the constitutive model are density dependent, and the specific forms of these parameters as functions of relative density are obtained. It can be concluded from the test results and constitutive model that the high relative density leads to increase in yield strength and energy absorption capacity of the materials and the strain rate also has positive effects on the yield strength and energy absorption capacity of porous bronze.

Similar content being viewed by others

References

Z.H. Wang, J.H. Shen, G.X. Lu, L.M. Zhao, Compressive behavior of closed-cell aluminum alloy foams at medium strain rates. Mater. Sci. Eng. A 528, 2326–2330 (2011)

Z.W. Zhou, Z.H. Wang, L.M. Zhao, X.F. Shu, Loading rate effect on yield surface of aluminum alloy foams. Mater. Sci. Eng. A 543, 193–199 (2012)

Z.W. Zhou, Z.H. Wang, L.M. Zhao, X.F. Shu, Uniaxial and biaxial failure behaviors of aluminum alloy foams. Compos. B 61, 340–349 (2014)

L. Jing, Z.H. Wang, L.M. Zhao, The dynamic response of sandwich panels with cellular metal cores to localized impulsive loading. Compos. B Eng. 94, 52–63 (2016)

L. Jing, Z.H. Wang, J.G. Ning et al., The dynamic response of sandwich beams with open-cell metal foam cores. Compos. Part B Eng. 42(1), 1–10 (2011)

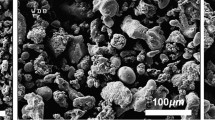

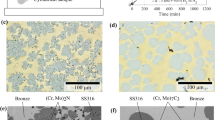

B. Wang, J.R. Klepaczko, G. Lu, L.X. Kong, Viscoplastic behavior of porous bronze and irons. J. Mater. Process. Technol. 113, 574–580 (2001)

E. Zhang, B. Wang, On the compressive behaviour of sintered porous coppers with low to medium porosities-part I: experimental study. Int. J. Mech. Sci. 47, 744–756 (2005)

B. Wang, E.L. Zhang, On the compressive behavior of sintered porous coppers with low-to-medium porosities—part II: preparation and microstructure. Int. J. Mech. Sci. 50, 550–558 (2008)

B. Wang, J. Zhang, G. Lu, Taylor impact test for ductile porous materials—part 2: experiments. Int. J. Impact Eng 28, 499–511 (2003)

G. Lu, B. Wang, T.G. Zhang, Taylor impact test for ductile porous materials—part 1: theory. Int. J. Impact Eng. 25, 981–991 (2001)

N. Iqbal, P. Xue, H.J. Liao, B. Wang, Y.L. Li, Material characterization of porous bronze at high strain rates. Mater. Sci. Eng. A 528, 4408–4412 (2011)

P. Xue, N. Iqbal, H.J. Liao, et al. Experimental study, on strain rate sensitivity of ductile porous irons. Int. J. Impact Eng. 2011: 1–5

M. Tane, Y.H. Song, H. Nakajima, Formation mechanism of a plateau stress region during dynamic compression of porous iron: interaction between oriented cylindrical pores and deformation twins. Mater. Sci. Eng. A 591, 150–158 (2014)

Y.H. Song, M. Tane, H. Nakajima, Dynamic and quasi-static compression of porous carbon steel S30C and S45C with directional pores. Mater. Sci. Eng. A 534, 504–513 (2012)

Y.H. Song, M. Tane, H. Nakajima, Appearance of a plateau stress region during dynamic compressive deformation of porous carbon steel with directional pores. Scr. Mater. 64, 797–800 (2011)

Y.H. Song, M. Tane, H. Nakajima, Peculiar formation mechanism of a plateau stress region during dynamic compressive deformation of porous carbon steel with oriented cylindrical pores. Acta Mater. 60, 1149–1160 (2012)

J. Zhang, L. Zhao, G. Lu, etc. High strain rate behavior of porous materials made of bronze and iron alloys. in Proceedings of 8th International Symposium on IMPLAST2003, pp. 333–342

Q.Z. Wang, D.M. Lu, C.X. Cui et al., Compressive behaviors and energy-absorption properties of an open-celled porous Cu fabricated by replication of NaCl space-holders. J. Mater. Process. Technol. 211, 363–367 (2011)

A.E. Simone, L.J. Gibson, Aluminum foams produced by liquid-state processes. Acta Mater. 46(9), 3109–3123 (1998)

B.A. Gama, S.L. Lopatnikov, J.W. Gillespie, Hopkinson bar experimental technique: a critical review. Appl. Mech. Rev. 57(4), 223–250 (2004)

Z.H. Wang, H.W. Ma, L.M. Zhao, G.T. Yang, Studies on the dynamic compressive properties of open-cell aluminum alloy foam. Scr. Mater. 54(1), 83–87 (2006)

Z.H. Wang, L. Jing, L.M. Zhao, Elasto-plastic constitutive model of aluminum alloy foam subjected to impact loading. Trans. Nonferr. Met. Soc. China 21, 449–454 (2011)

Y.G. Wang, L.L. Wang, Stress wave dispersion in large-diameter SHPB and its manifold manifestations. J. Beijing Inst. Technol. 13, 247–253 (2004)

P.S. Follansbee, C. Frantz, Wave propagation in the split Hopkinson pressure bar. J. Eng. Mater. Technol. 105, 61–66 (1983)

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant No. 11172196), Shanxi Scholarship Council of China (2013-046), the Top Young Academic Leaders of Shanxi and the Outstanding Innovative Teams of Higher Learning Institutions of Shanxi. The financial contributions are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Hu, J., Lei, J. et al. A parametric study on the dynamic behavior of porous bronze at various strain rates. Appl. Phys. A 122, 897 (2016). https://doi.org/10.1007/s00339-016-0433-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0433-9