Abstract

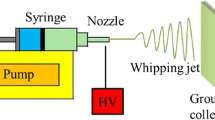

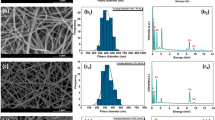

In this paper, the method for the fabrication of nanofibers based on poly(vinyl alcohol) (PVA) with controlled characteristics and surface morphology from binary solvent systems has been developed. Based on the Hildebrand–Scatchard theory of solubility, the calculated Teas diagrams, which take into account intermolecular interactions, made it possible to predict the formation of low-defect nanofibers based on PVA in systems of binary solvents with a higher proportion of hydrogen bonds. As a result of the findings, ethanol was determined to be a “inappropriate” solvent for the electrospinning PVA solution, whereas water and acetic acid displayed the properties of a “appropriate” solvent. The decrease in the volume of the unit cell with a slight decrease in the overall degree of crystallinity of the substance demonstrated the dependence of the change in the crystallization mechanism during the formation of PVA nanofibers on the transition from an individual aqueous polymer solution to the water/acetic acid binary solvent system. Compared with the results obtained during the PVA nanofibers fabrication from aqueous solution, the addition of 35% by weight of acetic acid to the aqueous solution of 8 wt% PVA allowed to lower the voltage from 30 to 26 kV and to increase the fiber fabrication yield by the increase in the flow rate from 0.2 to 0.3 mL/h. We confirmed that acetic acid has no effect on the chemical properties of PVA nanofibers however did change their lattice structure and reduce crystallinity of nanofibers. Such safe systems with controlled properties are suitable ones for biological active compounds encapsulation for drug delivery.

Similar content being viewed by others

References

Nawaz A, Hümmelgen IA (2019) Poly(vinyl alcohol) gate dielectric in organic field-effect transistors. J Mater Sci: Mater Electron 30:5299–5326. https://doi.org/10.1007/s10854-019-00873-5

Said M, Abd El-Azim AA, Ali MM et al (2020) Effect of elevated temperature on axially and eccentrically loaded columns containing polyvinyl alcohol (PVA) fibers. Eng Struct 204:110065. https://doi.org/10.1016/j.engstruct.2019.110065

Teodorescu M, Bercea M, Morariu S (2019) Biomaterials of PVA and PVP in medical and pharmaceutical applications: perspectives and challenges. Biotechnol Adv 37:109–131. https://doi.org/10.1016/j.biotechadv.2018.11.008

DeMerlis CC, Schoneker DR (2003) Review of the oral toxicity of polyvinyl alcohol (PVA). Food Chem Toxicol 41:319–326. https://doi.org/10.1016/s0278-6915(02)00258-2

Iqbal DN, Tariq M, Khan SM et al (2020) Synthesis and characterization of chitosan and guar gum based ternary blends with polyvinyl alcohol. Int J Biol Macromol 143:546–554. https://doi.org/10.1016/j.ijbiomac.2019.12.043

Nataraj D, Reddy R, Reddy N (2020) Crosslinking electrospun poly(vinyl) alcohol fibers with citric acid to impart aqueous stability for medical applications. Eur Polym J 124:109484. https://doi.org/10.1016/j.eurpolymj.2020.109484

Pervez MN, Stylios GK, Liang Y et al (2020) Low-temperature synthesis of novel polyvinylalcohol (PVA) nanofibrous membranes for catalytic dye degradation. J Clean Prod 262:121301. https://doi.org/10.1016/j.jclepro.2020.121301

DailyMed (2015) Current medication information for ARTIFICIAL TEARS- polyvinyl alcohol solution/drops. https://dailymed.nlm.nih.gov/dailymed/drugInfo.cfm?setid=2ef16864-97cb-4dfe-9461-cba156144c69

Kita M, Ogura Y, Honda Y et al (1990) Evaluation of polyvinyl alcohol hydrogel as a soft contact lens material. Graefes Arch Clin Exp Ophthalmol 228:533–537. https://doi.org/10.1007/BF00918486

Nargesi Khoramabadi H, Arefian M, Hojjati M et al (2020) A review of polyvinyl alcohol/carboxy methyl cellulose (PVA/CMC) composites for various applications. J Compos Comp 2(3):69–76. https://doi.org/10.29252/jcc.2.2.2

Abdallah OM, EL-Baghdady KZ, Khalil MMH et al (2020) Antibacterial, antibiofilm and cytotoxic activities of biogenic polyvinyl alcohol-silver and chitosan-silver nanocomposites. J Polym Res 27:74. https://doi.org/10.1007/s10965-020-02050-3

Yang Y, Zhao Y, Liu J et al (2020) Flexible and transparent high-dielectric-constant polymer films based on molecular ferroelectric-modified poly(vinyl alcohol). ACS Mater Lett 2:453–460. https://doi.org/10.1021/acsmaterialslett.0c00086

Xie Y, Lin X, Li H, Ji T (2020) Effect of polyvinyl alcohol powder on the bonding mechanism of a new magnesium phosphate cement mortar. Constr Build Mater 239:117871. https://doi.org/10.1016/j.conbuildmat.2019.117871

Reena KA, Mahto V, Choubey AK (2020) Synthesis and characterization of cross-linked hydrogels using polyvinyl alcohol and polyvinyl pyrrolidone and their blend for water shut-off treatments. J Mol Liq 301:112472. https://doi.org/10.1016/j.molliq.2020.112472

Hashmi M, Ullah S, Kim IS (2020) Electrospun momordica charantia incorporated polyvinyl alcohol (PVA) nanofibers for antibacterial applications. Mater Today Commun 24:101161. https://doi.org/10.1016/j.mtcomm.2020.101161

Muppalla SR, Kanatt SR, Chawla SP, Sharma A (2014) Carboxymethyl cellulose–polyvinyl alcohol films with clove oil for active packaging of ground chicken meat. Food Packag Shelf Life 2:51–58. https://doi.org/10.1016/j.fpsl.2014.07.002

Jiang Y, Schädlich A, Amado E et al (2010) In-vivo studies on intraperitoneally administrated poly(vinyl alcohol). J Biomed Mater Res B Appl Biomater 93B:275–284. https://doi.org/10.1002/jbm.b.31585

Zhang H, Zhang J (2020) The preparation of novel polyvinyl alcohol (PVA)-based nanoparticle/carbon nanotubes (PNP/CNTs) aerogel for solvents adsorption application. J Colloid Interface Sci 569:254–266. https://doi.org/10.1016/j.jcis.2020.02.053

Nwabor OF, Singh S, Paosen S et al (2020) Enhancement of food shelf life with polyvinyl alcohol-chitosan nanocomposite films from bioactive eucalyptus leaf extracts. Food Biosci 36:100609. https://doi.org/10.1016/j.fbio.2020.100609

Reguieg F, Ricci L, Bouyacoub N et al (2020) Thermal characterization by DSC and TGA analyses of PVA hydrogels with organic and sodium MMT. Polym Bull 77:929–948. https://doi.org/10.1007/s00289-019-02782-3

Musa BH, Hameed NJ (2020) Study of the mechanical properties of polyvinyl alcohol/starch blends. Mater Today Proc 20:439–442. https://doi.org/10.1016/j.matpr.2019.09.161

Kusumaatmaja A, Sukandaru B, Chotimah TK (2016) Application of polyvinyl alcohol nanofiber membrane for smoke filtration. AIP Conf Proc 1755:150006. https://doi.org/10.1063/1.4958579

Kim G, Doh SJ, Kim Y et al (2022) Electrospun polyvinyl alcohol composite nonwovens for air filtration materials in the humidity environment. Fibers Polym 23:690–698. https://doi.org/10.1007/s12221-022-3418-7

Yeo JH, Kim M, Lee H et al (2020) Facile and novel eco-friendly poly(vinyl alcohol) nanofilters using the photocatalytic property of titanium dioxide. ACS Omega 5:5026–5033. https://doi.org/10.1021/acsomega.9b03944

Kim H-J, Choi D-I, Sung S-K et al (2021) Eco-friendly poly(vinyl alcohol) nanofiber-based air filter for effectively capturing particulate matter. Appl Sci 11:3831. https://doi.org/10.3390/app11093831

Deng Y, Lu T, Zhang X et al (2022) Multi-hierarchical nanofiber membrane with typical curved-ribbon structure fabricated by green electrospinning for efficient, breathable and sustainable air filtration. J Memb Sci 660:120857. https://doi.org/10.1016/j.memsci.2022.120857

Deeksha B, Sadanand V, Hariram N, Rajulu AV (2021) Preparation and properties of cellulose nanocomposite fabrics with in situ generated silver nanoparticles by bioreduction method. J Bioresour Bioprod 6:75–81. https://doi.org/10.1016/j.jobab.2021.01.003

Teixeira MA, Amorim MTP, Felgueiras HP (2019) Poly(vinyl alcohol)-based nanofibrous electrospun scaffolds for tissue engineering applications. Polymers (Basel) 12:7. https://doi.org/10.3390/polym12010007

Coelho D, Sampaio A, Silva CJSM et al (2017) Antibacterial electrospun poly(vinyl alcohol)/enzymatic synthesized poly(catechol) nanofibrous midlayer membrane for ultrafiltration. ACS Appl Mater Interfaces 9:33107–33118. https://doi.org/10.1021/acsami.7b09068

Hasan A, Memic A, Annabi N et al (2014) Electrospun scaffolds for tissue engineering of vascular grafts. Acta Biomater 10:11–25. https://doi.org/10.1016/j.actbio.2013.08.022

Kong B, Mi S (2016) Electrospun scaffolds for corneal tissue engineering: a review. Materials 9:614. https://doi.org/10.3390/ma9080614

Gupta KC, Haider A, Choi Y, Kang I (2014) Nanofibrous scaffolds in biomedical applications. Biomater Res 18:5. https://doi.org/10.1186/2055-7124-18-5

Dhandayuthapani B, Yoshida Y, Maekawa T, Kumar DS (2011) Polymeric scaffolds in tissue engineering application: a review. Int J Polym Sci 2011:1–19. https://doi.org/10.1155/2011/290602

Shokry Hassan H, Kashyout AB, Morsi I et al (2014) Fabrication and characterization of gas sensor micro-arrays. Sens Biosens Res 1:34–40. https://doi.org/10.1016/j.sbsr.2014.04.001

Shokry Hassan H, Kashyout AB, Morsi I et al (2015) Development of polypyrrole coated copper nanowires for gas sensor application. Sens Biosens Res 5:50–54. https://doi.org/10.1016/j.sbsr.2015.07.004

Zhou Z-Q, Yan R, Zhao J et al (2018) Highly selective and sensitive detection of Hg2+ based on fluorescence enhancement of Mn-doped ZnSe QDs by Hg2+–Mn2+ replacement. Sens Actuators B Chem 254:8–15. https://doi.org/10.1016/j.snb.2017.07.033

Deng X, Zhang L, Guo J et al (2017) ZnO enhanced NiO-based gas sensors towards ethanol. Mater Res Bull 90:170–174. https://doi.org/10.1016/j.materresbull.2017.02.040

Venugopalan T, Yeo TL, Sun T, Grattan KTV (2008) LPG-based PVA coated sensor for relative humidity measurement. IEEE Sens J 8:1093–1098. https://doi.org/10.1109/JSEN.2008.926524

Zhou G, Byun J-H, Oh Y et al (2017) Highly sensitive wearable textile-based humidity sensor made of high-strength, single-walled carbon nanotube/poly(vinyl alcohol) filaments. ACS Appl Mater Interfaces 9:4788–4797. https://doi.org/10.1021/acsami.6b12448

Rivera-Hernández G, Antunes-Ricardo M, Martínez-Morales P, Sánchez ML (2021) Polyvinyl alcohol based-drug delivery systems for cancer treatment. Int J Pharm 600:120478. https://doi.org/10.1016/j.ijpharm.2021.120478

Rahmani F, Ziyadi H, Baghali M et al (2021) Electrospun PVP/PVA nanofiber mat as a novel potential transdermal drug-delivery system for buprenorphine: a solution needed for pain management. Appl Sci 11:2779. https://doi.org/10.3390/app11062779

Yang D, Li Y, Nie J (2007) Preparation of gelatin/PVA nanofibers and their potential application in controlled release of drugs. Carbohydr Polym 69:538–543. https://doi.org/10.1016/j.carbpol.2007.01.008

Desai N, Rana D, Salave S et al (2023) Chitosan: a potential biopolymer in drug delivery and biomedical applications. Pharmaceutics 15:1313. https://doi.org/10.3390/pharmaceutics15041313

Zahra FT, Quick Q, Mu R (2023) Electrospun PVA fibers for drug delivery: a review. Polymers (Basel) 15:3837. https://doi.org/10.3390/polym15183837

Farhaj S, Conway BR, Ghori MU (2023) Nanofibres in drug delivery applications. Fibers 11:21. https://doi.org/10.3390/fib11020021

Mallapragada SK, McCarthy-Schroeder S (2000) Poly(vinyl alcohol) as a drug delivery carrier. In: Wise DL (ed) Handbook of pharmaceutical controlled release technology. CRC Press, Boca Raton, pp 31–46. https://doi.org/10.1201/9781482289985

Hu X, Liu S, Zhou G et al (2014) Electrospinning of polymeric nanofibers for drug delivery applications. J Control Release 185:12–21. https://doi.org/10.1016/j.jconrel.2014.04.018

Li Q, Jia Z, Yang L et al (2008) Preparation and properties of poly(vinyl alcohol) nanofibers by electrospinning. J Polym Eng 28(1–2):87–100. https://doi.org/10.1515/POLYENG.2008.28.1-2.87

Oktay B, Kayaman-Apohan N, Erdem-Kuruca S (2014) Fabrication of nanofiber mats from electrospinning of functionalized polymers. IOP Conf Ser Mater Sci Eng 64:012011. https://doi.org/10.1088/1757-899X/64/1/012011

Park J-C, Ito T, Kim K-O et al (2010) Electrospun poly(vinyl alcohol) nanofibers: effects of degree of hydrolysis and enhanced water stability. Polym J 42:273–276. https://doi.org/10.1038/pj.2009.340

Uslu E, Gavgali M, Erdal MO et al (2021) Determination of mechanical properties of polymer matrix composites reinforced with electrospinning N66, PAN, PVA and PVC nanofibers: a comparative study. Mater Today Commun 26:101939. https://doi.org/10.1016/j.mtcomm.2020.101939

Lee JS, Choi KH, Do GH et al (2004) Role of molecular weight of atactic poly(vinyl alcohol) (PVA) in the structure and properties of PVA nanofabric prepared by electrospinning. J Appl Polym Sci 93:1638–1646. https://doi.org/10.1002/app.20602

Fadil F, Adli FA, Affandi NDN et al (2020) Dope-dyeing of polyvinyl alcohol (PVA) nanofibres with remazol yellow FG. Polymers (Basel) 12:3043. https://doi.org/10.3390/polym12123043

Shi Y, Zhao Y, Li X et al (2018) Enhancement of the mechanical properties and thermostability of poly(vinyl alcohol) nanofibers by the incorporation of sodium chloride. J Appl Polym Sci 135:45981. https://doi.org/10.1002/app.45981

Rwei S, Huang C-W, Hung C-C (2012) Electrospinning PVA solution-rheology and morphology analyses. Fibers Polym 13:44. https://doi.org/10.1007/s12221-012-0044-9

Itoh H, Li Y, Chan KHK, Kotaki M (2016) Morphology and mechanical properties of PVA nanofibers spun by free surface electrospinning. Polym Bull 73:2761–2777. https://doi.org/10.1007/s00289-016-1620-8

Medina EF, Arjona SD, Corrales FZ, Borras VA (2013) Morphological and mechanical response characterization of nanofiber aggregates of PVA produced by electrospinning sol–gel process. Dyna 80(178):109–114

Alwan TJ, Toma ZA, Kudhier MA, Ziadan KM (2016) Preparation and characterization of the PVA nanofibers produced by electrospinning. Madridge J Nanotechnol Nanosci 1:1–3. https://doi.org/10.18689/mjnn-1000101

Mahmud MM, Perveen A, Matin MA, Arafat MT (2018) Effects of binary solvent mixtures on the electrospinning behavior of poly(vinyl alcohol). Mater Res Express 5:115407. https://doi.org/10.1088/2053-1591/aadf1f

Bunn CW (1948) Crystal structure of polyvinyl alcohol. Nature 161:929–930. https://doi.org/10.1038/161929a0

International organization for standardization (2018) International standard ISO 527-3:2018, plastics—determination of tensile properties—part 3: test conditions for films and sheets. International organization for standardization

Dahl PL (1982) A viscous friction model. A thesis submitted in partial satisfaction of the requirements for the degree of Master of Science in Engineering, California State University

Madhlopa A (2022) Hydrodynamics of solar receivers. In: Solar receivers for thermal power generation. Elsevier, pp 213–250. ISBN 978-0-323-85271-5. https://doi.org/10.1016/B978-0-323-85271-5.00008-2

Marinescu ID, Rowe WB, Dimitrov B, Inasaki I (2004) Process fluids for abrasive machining. In: Tribology of abrasive machining processes. Elsevier, pp 531–585. ISBN 9780815519386

Gao H, He J, Yang R, Yang L (2010) Characteristic rheological features of high concentration PVA solutions in water with different degrees of polymerization. J Appl Polym Sci 116(5):2734–2741. https://doi.org/10.1002/app.31900

Briscoe B, Luckham P, Zhu S (2000) The effects of hydrogen bonding upon the viscosity of aqueous poly(vinyl alcohol) solutions. Polymer (Guildf) 41:3851–3860. https://doi.org/10.1016/S0032-3861(99)00550-9

Song SI, Kim BC (2004) Characteristic rheological features of PVA solutions in water-containing solvents with different hydration states. Polymer (Guildf) 45:2381–2386. https://doi.org/10.1016/j.polymer.2004.01.057

Marten FL (2002) Vinyl alcohol polymers. In: Encyclopedia of polymer science and technology. Wiley, Hoboken, NJ, Print ISBN: 9781118633892. Online ISBN: 9780471440260. https://doi.org/10.1002/0471440264

Sawamura S, Yoshimura Y, Kitamura K, Taniguchi Y (1992) Effects of pressure, temperature, and concentration on the viscosity of an aqueous solution of sodium chloride. J Phys Chem 96:5526–5529. https://doi.org/10.1021/j100192a063

Finch CA (1973) Polyvinyl alcohol; properties and applications. Wiley, Chichester

Maeda H, Kawai T, Sekii S (1959) Intra- and intermolecular hydrogen bonds in polyvinyl alcohol solutions. J Polym Sci 35:288–292. https://doi.org/10.1002/pol.1959.1203512831

Phachamud Th, Phiriyawirut M (2011) Physical properties of polyvinyl alcohol electrospun fiber mat. Res J Pharm Biol Chem Sci 2:675–684

Lebedeva AV, Nhung VTH, Olekhnovich RO et al (2022) Investigation of the fabrication of nanofibers from aqueous polyvinyl alcohol solutions by electrospinning. Proc VSUET 84:210–220. https://doi.org/10.20914/2310-1202-2022-2-210-220

Polyvinyl alcohol (PVA)—61st joint FAO/WHO expert committee on food additives (JECFA) meeting—chemical and technical assessment (CTA) (2003)

der Lösungen ZT (1887) Zur Theorie der Lösungen, pp 17–18

Deitzel JM, Kleinmeyer J, Harris D, Beck Tan NC (2001) The effect of processing variables on the morphology of electrospun nanofibers and textiles. Polymer (Guildf) 42:261–272. https://doi.org/10.1016/S0032-3861(00)00250-0

Ni Q, Ye W, Du M et al (2022) Effect of hydrogen bonding on dynamic rheological behavior of pva aqueous solution. Gels 8:518. https://doi.org/10.3390/gels8080518

Xiansu C, Huaimin G, Yingcao S, Jiafang W (2001) Inclusion compound of poly(vinyl alcohol) with multivalent molybdenum coordination compound. J Inorg Organomet Polym Mater 11:235–245. https://doi.org/10.1023/A:1020516511165

Wendorff J, Agarwal S, Greiner A (2012) Electrospinning: materials, processing, and applications. Wiley, Weinheim. https://doi.org/10.1002/9783527647705

Bhardwaj N, Kundu SC (2010) Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv 28:325–347. https://doi.org/10.1016/j.biotechadv.2010.01.004

Greiner A, Wendorff JH (2007) Electrospinning: a fascinating method for the preparation of ultrathin fibers. Angew Chem Int Ed Engl 46:5670–5703. https://doi.org/10.1002/anie.200604646

Senthamizhan A, Balusamy B, Uyar T (2017) Electrospinning. In: Electrospun materials for tissue engineering and biomedical applications. Elsevier, pp 3–41. https://doi.org/10.1016/B978-0-08-101022-8.00001-6

Burke J (1984) Solubility parameters: theory and application. The book and paper group of the american institute for conservation

Tretinnikov ON, Zagorskaya SA (2012) Determination of the degree of crystallinity of poly(vinyl alcohol) by FTIR spectroscopy. J Appl Spectrosc 79:521–526. https://doi.org/10.1007/s10812-012-9634-y

Hu S, Tsuji M, Horiit F (1994) Phase structure of poly(vinyl alcohol) single crystals as revealed by high-resolution solid-state 13C n.m.r, spectroscopy. Polymer 35(12):2516–2522. https://doi.org/10.1016/0032-3861(94)90372-7

Anicuta S, Dobre L, Stroescu M, Jipa I (2010) Fourier transform infrared (FTIR) spectroscopy for characterization of antimicrobial films containing chitosan. Analele Universitatii din Oradea Fascicula: Ecotoxicologie, Zootehnie si Tehnologii de Industrie Alimentara, pp 1234–1240

Wu J, Wang N, Wang L et al (2012) Unidirectional water-penetration composite fibrous film via electrospinning. Soft Matter 8:5996–5999. https://doi.org/10.1039/C2SM25514F

Aruan N, Sriyanti I, Edikresnha D et al (2017) Polyvinyl alcohol/soursop leaves extract composite nanofibers synthesized using electrospinning technique and their potential as antibacterial wound dressing. Procedia Eng 170:31–35. https://doi.org/10.1016/j.proeng.2017.03.006

Otsuka E, Komiya S, Sasaki S et al (2012) Effects of preparation temperature on swelling and mechanical properties of PVA cast gels. Soft Matter 8:8129. https://doi.org/10.1039/c2sm25513h

Otsuka E, Suzuki A (2009) A simple method to obtain a swollen PVA gel crosslinked by hydrogen bonds. J Appl Polym Sci 114:10–16. https://doi.org/10.1002/app.30546

Nagara Y, Nakano T, Okamoto Y et al (2001) Properties of highly syndiotactic poly(vinyl alcohol). Polymer (Guildf) 42:9679–9686. https://doi.org/10.1016/S0032-3861(01)00493-1

Uda A, Morita S, Ozaki Y (2013) Thermal degradation of a poly(vinyl alcohol) film studied by multivariate curve resolution analysis. Polymer (Guildf) 54:2130–2137. https://doi.org/10.1016/j.polymer.2013.02.030

Funding

The authors have no financial or proprietary interests in any material discussed in this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vu, T.H.N., Morozkina, S.N., Sitnikova, V.E. et al. The influence of acetic acid and ethanol on the fabrication and properties of poly(vinyl alcohol) nanofibers produced by electrospinning. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05168-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05168-2