Abstract

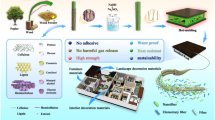

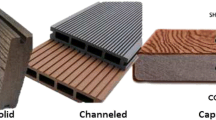

Wood-plastic composites contain a high proportion of wood fibres with a reduced dependence on mineral oil. In addition to decking boards, linear façade panels are also frequently produced. The thermoplastic matrix enables subsequent forming under heat for the creation of three-dimensional façades, which offers new design options. To date, in previous studies, effects from the extrusion process itself on essential product properties have been reported; e.g. the maximum extrusion temperature must not exceed 210 °C to protect the wood fibre, and higher compound compaction increases material strength. However, the conditions and effects from later reheating for the purpose of reshaping existing profiles into curved elements have rarely been addressed. This study investigates how intensively decisive application-specific mechanical properties change after postprocess hot pressing under different combinations of temperature, heating duration and pressing force. Comparative tests were carried out on two commercially available WPCs with different wood contents. The flexural strength of both sample types reacted most sensitively to heat, followed by the stiffness modulus, which was significant only for the high-fibre type. A longer heating time at a lower temperature, on the other hand, counteracted the loss of strength. The impact resistance hardly changed, and the Brinell hardness was not affected at all. With regard to fastener withdrawal, both WPC types showed contrasting behaviour. Overall, the results indicate an effective use of postprocess hot pressing of WPCs in façades with partwise significant but calculable changes in WPC properties.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Roig I (2018) Biocomposites for interior façades and partitions to improve air quality in new buildings and restorations. Reinf Plast 62:270–274

Sommerhuber PF, Wenker JL, Rüter S, Krause A (2017) Life cycle assessment of wood-plastic composites: Analysing alternative materials and identifying an environmental sound end-of-life option. Resour Conserv Recycl 117:235–248. https://doi.org/10.1016/j.resconrec.2016.10.012

Carus M, Gahle C, Korte H (2008) Market and future trends for wood-polymer composites in Europe: the example of Germany Wood-Polymer Composites Woodhead Publishing Series in Composites Science and Engineering 300–330. https://doi.org/10.1533/9781845694579.300

Statista (2021) Forecast for sales of wood-polymer materials worldwide from 2014 to 2022, https://de.statista.com/statistik/daten/studie/668616/umfrage/prognose-zum-globalen-marktvolumen-fuer-wpc (accessed 3 Sep 2021)

Carus M, Dammer L, Scholz L, Essel R, Breitmayer E, Eder A, Korthe H (2014) European and Global Markets 2012 and Future Trends. Bioplast Mag 9:42–44

Carus M (2015) Eder, A. WPC and NFC market trends, bioplastics Magazine 10:12–13

Teuber L, Osburg VS, Toporowski W, Militz H, Krause A (2016) Wood polymer composites and their contribution to cascading utilization. J Clean Prod 110:9–15. https://doi.org/10.1016/j.jclepro.2015.04.009

Sijtsema SJ, Onwezen MC, Reinders MJ, Dagevos H, Partanen A, Meeusen M (2016) Consumer perception of biobased products - an exploratory study in 5 European countries. NJAS - Wageningen J Life Sci 77:61–69. https://doi.org/10.1016/j.njas.2016.03.007

Eder A, Carus M (2013) Global trends in wood-plastic composites (WPC). Bioplastics Magazin 8:16–17

Stanaszek-Tomal E (2020) Recycling of wood-polymer composites in relation to substrates and finished products. IOP Conference Series: materials Science and Engineering 960: 022053 https://doi.org/10.1088/1757-899X/960/2/022053

Kuzman MK, Klaric S, Baršic AP, Vlosky RP, Janakieska MM, Grošelj P (2018) Architect perceptions of engineered wood products: an exploratory study of selected countries in Central and Southeast Europe. Constr Build Mater 179:360–370. https://doi.org/10.1016/j.conbuildmat.2018.05.164

Ghomeshi M (2013) Jusan, M, investigating different aesthetic preferences between architects and non-architects in residential facade designs. Indoor Built Environ 22:952–964. https://doi.org/10.1177/1420326X12458513

Takano A, Hughes M, Winter S (2014) A multidisciplinary approach to sustainable building material selection: a case study in a Finnish context. Build Environ 82:526–535. https://doi.org/10.1016/j.buildenv.2014.09.026

Friedrich D (2021) Attitude of building experts towards novel biobased wood-polymer façades under various properties: a choice-based experiment and impact analysis. J Build Eng 35:102079. https://doi.org/10.1016/j.jobe.2020.102079

Friedrich D (2021) Thermoplastic moulding of wood-polymer composites (WPC): a review on physical and mechanical behaviour under hot-pressing technique. Compos Struct 262:113649. https://doi.org/10.1016/j.compstruct.2021.113649

Sukiman MS, Erchiqui F, Kanit T, Imad A (2020) Design and numerical modeling of the thermoforming process of a WPC based formwork structure. Mater Today Commun 22:100805. https://doi.org/10.1016/j.mtcomm.2019.100805

Hamel S, Hermanson J, Cramer S (2012) Mechanical and time-dependent behavior of wood-plastic composites subjected to tension and compression. J Thermoplast Compos Mater 26:968–987. https://doi.org/10.1177/0892705711432362

Guo X, Cao J, Peng Y, Liub R (2016) Incorporation of microencapsulated dodecanol into wood flour/high-density polyethylene composite as a phase change material for thermal energy storage. Mater Des 89:1325–1334

Jamekhorshid A, Sadrameli SM, Barzin R, Farid M (2017) Composite of wood-plastic and micro-encapsulated phase change material (MEPCM) used for thermal energy storage. Appl Therm Eng 112:82–88

Jingchen X, Keyan Y, Yucheng Z, Yuxiang Y, Jianmin C, Liping C, Sheldon SQ (2020) Form-stable phase change material based on fatty acid/wood flour composite and PVC used for thermal energy storage. Energy & Build 209:109663

Zhao Q, Zou W, Luo Y, Xie T (2016) Shape memory polymer network with thermally distinct elasticity and plasticity. Sci Adv 2:e1501297

Inomata K, Nakagawa K, Fukuda C, Nakada Y, Sugimoto H, Nakanishi E (2010) Shape memory behavior of poly(methyl methacrylate)-graft-poly(ethylene glycol) copolymers. Polymer 51:793–798

Konsta (2021) https://cdn.hornbach.de/data/shop/D04/001/780/491/888/217/6018704_Doc_01_DE_20201012094653.pdf (accessed 3 Sep 2021)

Fiberon (2021) https://www.fiberondecking.com/faq/what-is-the-significance-of-using-hdpe-to-make-fiberon-decking (accessed 3 Sep 2021)

Ayrilmis N, Benthien JT (2012) Thoemen, H., Effects of formulation variables on surface properties of wood plastic composites. Compos B 43:325–331. https://doi.org/10.1016/j.compositesb.2011.07.011

Hosseini S (2013) Effects of Dioctyl phthalate and density changes on the physical and mechanical properties of woodflour/PVC composites. J the Indian Acad Wood Sci 10(1):20–25

Benthien JT (2012) Thoemen, H., Effects of raw materials and process parameters on the physical and mechanical properties of flat pressed WPC panels. Compos A 43:570–576. https://doi.org/10.1016/j.compositesa.2011.12.028

Dimitriou A, Hale MD, Spear M (2018) The effect of four methods of surface activation for improved adhesion of wood polymer composites (WPCs). Int J Adhes Adhes 68:188–194. https://doi.org/10.1016/j.ijadhadh.2016.03.003

Mohamed MR, Naguib HM, El-Ghazawy RA, Shaker NO, Amer AA, Soliman AM, Kandil UF (2019) Surface activation of wood plastic composites (WPC) for enhanced adhesion with epoxy coating. Mater Perform Charact 8:22–40. https://doi.org/10.1520/MPC20180034

Ghahri S, Najafi SK, Mohebby B, Tajvidi M (2011) Impact strength improvement of wood flour-recycled polypropylene composites. J Appl Polym Sci 124:1074–1080. https://doi.org/10.1002/app.34015

Bekhta P, Proszyk S, Krystofiak T, Sedliacik J, Novak I, Mamonova M (2017) Effects of short-term thermomechanical densification on the structure and properties of wood veneers. Wood Mat Sci Eng 12:40–54. https://doi.org/10.1080/17480272.2015.1009488

Kaymakci A, Birinci E, Ayrilmis C (2019) Surface characteristics of wood polypropylene nanocomposites reinforced with multi-walled carbon nanotubes. Compos B 157:43–46. https://doi.org/10.1016/j.compositesb.2018.08.099

Unsal O, Candan Z, Korkut S (2011) Wettability and roughness characteristics of modified wood boards using a hot-press. Ind Crops Prod 34:1455–1457. https://doi.org/10.1016/j.indcrop.2011.04.024

Hoong JB, Paridah T (2013) Development a new method for pilot scale production of high grade oil palm plywood: effect of hot-pressing time. Mater Des 45:142–147. https://doi.org/10.1016/j.matdes.2012.08.054

Stark NM, Matuana LM, Clemons CM (2003) Effect of processing method on accelerated weathering of woodflour-HDPE composites. In: Seventh international conference on wood-fiber-plastic composites (and other natural fibers), May 19–20 Madison, Wisconsin, USA

Połec IA, Hine PJ, Bonner MJ, Ward IM, Barton DC (2012) Hydro and thermal stability of die drawn wood polymer composites in comparison to solid wood. Compos Sci Technol 72:1436–1442

Chaudemanche S, Perrot A, Pimbert S, Lecompte T, Faure F (2018) Properties of an industrial extruded HDPE-WPC: The effect of the size distribution of wood flour particles. Constr Build Mater 162:543–552. https://doi.org/10.1016/j.conbuildmat.2017.12.061

Ndiaye D, Verney V, Askanian H, Commereuc S, Tidjani A (2013) Morphology Thermal Behavior and Dynamic Rheological Properties of Wood olypropylene Composites. Mater Sci Appl 4

Lyutyy P, Bekhta P, Sedliacik J, Ortynska G (2014) Properties of flat-pressed wood-polymer composites made using secondary polyethylene. Acta Facultatis Xylologiae Zvolen 56:39–50

Kaymakci A, Ayrilmis N, Gulec T (2013) Surface Properties and Hardness of Polypropylene Composites Filled With Sunflower Stalk Flour. BioResources 8:592–602

DIN EN 15534–1:2018–02, Composites made from cellulose-based materials and thermoplastics (usually called wood-polymer composites (WPC) or natural fibre composites (NFC)) - Part 1: Test methods for characterisation of compounds and products

Zhou X, Huang S, Chen L (2016) Effect of antiaging agents on the outdoor natural weathering of bamboo powder/polypropylene foamed composites. J Vinyl Add Tech 22:311–319

Sae-Lim P, Aht-Ong D (2013) Physical and mechanical properties of wood-plastics composites: effect of types and contents of wood flour. Adv Mater Res 747:379–382. https://doi.org/10.4028/www.scientific.net/AMR.747.379

Oladejo KO, Omoniyi TE (2017) Dimensional stability and mechanical properties of wood plastic composites produced from sawdust of anogeissus leiocarpus (Ayin) with recycled polyethylene teraphthalate (PET) chips. European J Appl Eng Sci Res 5:28–33

Rahman KS, Islam N, Rahman M, Hannan O, Dungani R, Khalil A (2013) Flat-pressed wood plastic composites from sawdust and recycled polyethylene terephthalate (PET): physical and mechanical properties. Springerplus 2:629. https://doi.org/10.1186/2193-1801-2-629

Gozdecki C, Wilczyski A, Kociszewski M (2013) Effect of high temperature on the mechanical properties of wood-polymer composites. Forestry Wood Technol 82:291–294

Charlet K, Saulnier F, Dubois M, Béakou A (2015) Improvement of wood polymer composite mechanical properties by direct fluorination. Mater Des 74:61–66. https://doi.org/10.1016/j.matdes.2015.02.012

Fortini A, Mazzanti V (2018) Combined effect of water uptake and temperature on wood polymer composites: research article. J Appl Polym Sci 135:46674. https://doi.org/10.1002/app.46674

Vedrtnam A, Kumar S, Chaturvedi S (2019) Experimental study on mechanical behavior, biodegradability, and resistance to natural weathering and ultraviolet radiation of wood-plastic composites. Compos B 176:107282. https://doi.org/10.1016/j.compositesb.2019.107282

Kaymakci A (2014) Ayrilmis, N., Investigation of correlation between Brinell hardness and tensile strength of wood plastic composites. Compos B 58:582–585. https://doi.org/10.1016/j.compositesb.2013.11.009

Arnandha Y, Satyarno I, Awaludin A, Irawati I, Ihsan M, Wijanarko B, Mahdinur W, Fardhani A (2017) Evaluation of bolted connections in wood-plastic composites. AIP Conf Proc 1818:020006. https://doi.org/10.1063/1.4976870

Yorur H, Birinci E, Gunay M, Tor O (2020) Effects of factors on direct screw withdrawal resistance in medium density fiberboard and particleboard. Maderas Ciencia y tecnología. https://doi.org/10.4067/S0718-221X2020005000311

Ghanbari A, Madhoushi M, Ashori A (2014) Wood plastic composite panels: influence of the species, formulation variables and blending process on the density and withdrawal strength of fasteners. J Polym Environ 22:260–266. https://doi.org/10.1007/s10924-013-0634-7

Cohen J (1988) Statistical power analysis for the behavioral sciences. L Erlbaum Associates, Hilsdale, NJ

Badji C, Soccalingame L, Garay H, Bergeret A, Benezet JC (2017) Influence of weathering on visual and surface aspect of wood plastic composites: correlation approach with mechanical properties and microstructure. Polym Degrad Stab 137:162–172

Homkhiew C, Ratanawilai T, Thongruang W (2014) Effects of natural weathering on the properties of recycled polypropylene composites reinforced with rubberwood flour. Ind Crops Prod 56:52–59

Durmaz S, Erdil Y, Avci E (2020) Screw withdrawal resistance and surface roughness of woven carbon and glass fiber-reinforced wood-plastic composites. BioResources 15:1894–1903

Yang X, Ma L (2018) Zhao, Q, Yu, Z., Enduring performance of self-tapping screw connection in wood members and WPC members. Wood Research 63:833–842

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors. The author gratefully acknowledges the collaborative work with Prof. Dr. Rosemarie Wagner, Institute of Architecture at Karlsruhe Institute of Technology (KIT), where he conducts further research in the topic of this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Friedrich, D. Change in key mechanical properties from postprocess hot pressing of commercial wood-plastic composites with different fibre contents. Polym. Bull. 80, 4263–4288 (2023). https://doi.org/10.1007/s00289-022-04251-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04251-w