Abstract

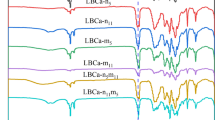

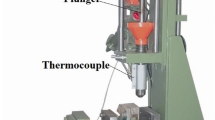

In this study, blends of poly (caprolactone) (PCL) with different content of coir fibre (CF) (2, 2.5 and 5 wt%) were fabricated by solvent casting technique to obtain a biodegradable composite. The PCL/CF composites obtained have been characterised using the X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM) and Electrodynamic fatigue testing machines. According to XRD patterns, the intensity of the peak in the pure PCL spectrum was found to decrease by the addition of coir fibre which then disappears when the CF content is 5 wt% is indicating that coir fibre inhibited the diffusion and deposition of PCL molecules. The FTIR absorption spectra for the PCL/CF blends showed that there was no new peak to represent the chemical interaction between the functional groups of coir fibre and poly (caprolactone). The SEM micrographs of the composites indicate inadequate wetting of coir fibre as filler content increases due to poor dispersion and interfacial adhesion. The tensile strength of the composites samples was found to increase with an increase in the fibre content up to 2.5 wt% on addition of coir fibre but with a reduction from 16.79 N/mm2 for the neat polymer to 5.08 N/mm2 for the blend with 5 wt% coir fibre (a 69.74% decrease). The addition of coir fibre reduces the elongation at break of the composites, whereas the Young modulus value of composites goes on increasing up to 182 N/mm2 for coir fibres volume fraction of 2.5 wt%. The behaviour of samples with high fibre content could be explained by insufficient fibre wetting and poor interfacial adhesion with no coupling agent in addition to the low aspect ratio of the coir particles.

Similar content being viewed by others

References

Zhang J, Duan Y, Sato H et al (2005) Crystal modifications and thermal behaviour of poly (l-lactic acid) revealed by infrared spectroscopy. Macromolecules 38:8012–8021

Yoshii F, Darwis D, Mitomo H, Makuuchi K (2000) Crosslinking of poly (ε-caprolactone) by radiation technique and its biodegradability. Radiat Phys Chem 57:417–420

Tsuji H, Ikada Y (1996) Blends of aliphatic polyesters. I. Physical properties and morphologies of solution-cast blends from poly (DL-lactide) and poly (ε-caprolactone). J Appl Polym Sci 60:2367–2375

Dell’Erba R, Groeninckx G, Maglio G, Malinconico M, Migliozzi A (2001) Immiscible polymer blends of semicrystalline biocompatible components: thermal properties and phase morphology analysis of PLLA/PCL blends. Polymer 42:7831–7840

Kammer H, Kummerlöwe C (1994) Poly (-caprolactone) comprising blends-phase behavior and thermal properties. Adv Polym Blends Alloys Technol 5:132

Pasquini D, de Morais Teixeira E, da Silva Curvelo AA, Belgacem MN, Dufresne A (2008) Surface esterification of cellulose fibres: processing and characterisation of low-density polyethylene/cellulose fibres composites. Compos Sci Technol 68:193–201

Torres F, Cubillas M (2005) Study of the interfacial properties of natural fibre reinforced polyethylene. Polym Testing 24:694–698

Dominkovics Z, Danyadi L, Pukanszky B (2007) Surface modification of wood flour and its effect on the properties of PP/wood composites. Compos A Appl Sci Manuf 38:1893–1901

Bengtsson M, Le Baillif M, Oksman K (2007) Extrusion and mechanical properties of highly filled cellulose fibre–polypropylene composites. Compos A Appl Sci Manuf 38:1922–1931

Zampaloni M, Pourboghrat F, Yankovich S et al (2007) Kenaf natural fibre reinforced polypropylene composites: a discussion on manufacturing problems and solutions. Compos A Appl Sci Manuf 38:1569–1580

Guffey VO, Sabbagh AB (2002) PVC/wood flour composites compatibilized with chlorinated polyethylene. J Vinyl Add Tech 8:259

Mishra S, Naik J (2005) Effect of treatment of maleic anhydride on mechanical properties of natural fibre: polystyrene composites. Polym Plastic Technol Eng 44:663–675

Ku H, Wang H, Pattarachaiyakoop N, Trada M (2011) A review on the tensile properties of natural fibre reinforced polymer composites. Compos B Eng 42:856–873

Mahzan S, Ahmad Zaidi AM, Arsat N, Hatta MNM, Ghazali MI, Rasool Mohideen S (2010) Study on sound absorption properties of coconut coir fibre reinforced composite with added recycled rubber. Int J Integr Eng 2:29–34

Misra R, Kumar S, Sandeep K, Misra A (2008) Some experimental and theoretical investigations on fire retardant coir/epoxy micro-composites. J Thermoplast Compos Mater 21:71–101

Monteiro S, Terrones L, D’almeida J (2008) Mechanical performance of coir fibre/polyester composites. Polym Testing 27:591–595

Júnior HS, Lopes F, Costa L, Monteiro S (2010) Mechanical properties of tensile tested coir fibre reinforced polyester composites. Rev Mater 15:113–118

Hussain SA, Pandurangadu V, Palanikuamr K (2011) Mechanical properties of green coconut fibre reinforced HDPE polymer composite. Int J Eng Sci Technol 3:7942–7952

Roy JK, Akter N, Zaman HU et al (2014) Preparation and properties of the coir fiber-reinforced ethylene glycol dimethacrylate-based composite. J Thermoplast Compos Mater 27:35–51

Borghesi DC, Molina MF, Guerra MA, Campos MGN (2016) Biodegradation study of a novel poly-caprolactone-coffee husk composite film. Mater Res 19(4):752–758

Ludueña L, Vázquez A, Alvarez V (2012) Effect of lignocellulosic filler type and content on the behaviour of polycaprolactone-based eco-composites for packaging applications. Carbohyd Polym 87:411–421

Hamid MZA, Ibrahim NA, Yunus WMZW, Zaman K, Dahlan M (2010) Effect of grafting on properties of oil palm empty fruit bunch fibre reinforced polycaprolactone biocomposites. J Reinf Plast Compos 29:2723–2731

Zhao Q, Tao J, Yam RC, Mok AC, Li RK, Song C (2008) Biodegradation behaviour of polycaprolactone/rice husk eco-composite in simulated soil medium. Polym Degrad Stab 93:1571–1576

Pappu A, Saxena M, Thakur VK, Sharma A, Haque R (2016) Facile extraction, processing and characterization of biorenewable sisal fibres for multifunctional applications. J Macromol Sci Part A 53:424–432

Arbelaiz A, Fernández B, Valea A, Mondragon I (2006) Mechanical properties of short flax fibre bundle/poly (ε-caprolactone) composites: influence of matrix modification and fibre content. Carbohyd Polym 64:224–232

Nitz H, Semke H, Landers R, Mülhaupt R (2001) Reactive extrusion of polycaprolactone compounds containing wood flour and lignin. J Appl Polym Sci 81:1972–1984

Siqueira G, Bras J, Follain N, Belbekhouche S, Marais S, Dufresne A (2013) Thermal and mechanical properties of bio-nanocomposites reinforced by Luffa cylindrica cellulose nanocrystals. Carbohyd Polym 91:711–717

Iannace S, Nocilla G, Nicolais L (1999) Biocomposites based on sea algae fibres and biodegradable thermoplastic matrices. J Appl Polym Sci 73:583–592

Pappu A, Patil V, Jain S, Mahindrakar A, Haque R, Thakur VK (2015) Advances in industrial prospective of cellulosic macromolecules enriched banana fibre resources: a review. Int J Biol Macromol 79:449–458

Satyanarayana K, Pillai C, Sukumaran K, Pillai S, Rohatgi P, Vijayan K (1982) Structure property studies of fibres from various parts of the coconut tree. J Mater Sci 17:2453–2462

Owolabi O, Czvikovszky T, Kovacs I (1985) Coconut-fiber-reinforced thermosetting plastics. J Appl Polym Sci 30:1827–1836

Choudhury A, Kumar S, Adhikari B (2007) Recycled milk pouch and virgin low-density polyethylene/linear low-density polyethylene based coir fibre composites. J Appl Polym Sci 106:775–785

Geethamma V, Mathew KT, Lakshminarayanan R, Thomas S (1998) Composite of short coir fibres and natural rubber: effect of chemical modification, loading and orientation of fibre. Polymer 39:1483–1491

Goldberg D (1995) A review of the biodegradability and utility of poly (caprolactone). J Environ Polym Degrad 3:61–67

Kirby R (1963) Vegetable Fibres: World Crop Series. Leonard Hill, Interscience, London, New York

Lewin M, Pearce E (1985) Fibre chemistry. Handbook of fibre science and technology, vol 4. Marcel Dekker Inc, New York and Basel

Liu J, Reni L, Wei Q et al (2011) Fabrication and characterization of polycaprolactone/calcium sulphate whisker composites. Express Polym Lett 5:742–752

Oh SY, Yoo DI, Shin Y, Seo G (2005) FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohyd Res 340:417–428

Erdtman H (1971) Lignins: occurrence, formation, structure and reactions, K. V. Sarkanen and C. H. Ludwig, Eds., John Wiley & Sons, Inc., New York. 916 pp. $35.00. J Polym Sci Part B Polym Lett 10(3):228–230

Klemm D, Schumann D, Kramer F et al (2006) Nanocelluloses as innovative polymers in research and application. Polysaccharides Ii. Springer, New York, pp 49–96

Klemm D, Philipp B, Heinze T, Heinze U, Wagenknecht W (2004) General considerations on structure and reactivity of cellulose: section 2.4–2.4. 3. Compr Cell Chem Fundam Anal Methods 1:130–165

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres. Fourier transform–materials analysis. InTech

Yeh JT, Yang MC, Wu CJ, Wu CS (2009) Preparation and characterization of biodegradable polycaprolactone/multiwalled carbon nanotubes nanocomposites. J Appl Polym Sci 112:660–668

Agarwal K, Prasad M, Sharma R, Setua D (2011) Studies on microstructural and thermophysical properties of polymer nanocomposite based on polyphenylene oxide and Ferrimagnetic iron oxide. Polym Testing 30:155–160

Rao KMM, Rao KM (2007) Extraction and tensile properties of natural fibres: vakka, date and bamboo. Compos Struct 77:288–295

Brahim SB, Cheikh RB (2007) Influence of fibre orientation and volume fraction on the tensile properties of unidirectional Alfa-polyester composite. Compos Sci Technol 67:140–147

Graupner N (2009) Improvement of the mechanical properties of biodegradable hemp fibre reinforced poly (lactic acid)(PLA) composites by the admixture of man-made cellulose fibres. J Compos Mater 43:689–702

Zhou J, Tang J, Meng H, Yu J (2008) Study on PP/calcium sulphate whisker composite. Eng Plastics Appl 36:19–22

Thomason J (2009) The influence of fibre length, diameter and concentration on the impact performance of long glass fibre reinforced polyamide 6, 6. Compos A Appl Sci Manuf 40:114–124

Acknowledgements

We acknowledge the financial support by The World Academy of Science (TWAS), and COMSATS Institute of Information Technology (CIIT), Pakistan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Obasi, H.C., Chaudhry, A.A., Ijaz, K. et al. Development of biocomposites from coir fibre and poly (caprolactone) by solvent casting technique. Polym. Bull. 75, 1775–1787 (2018). https://doi.org/10.1007/s00289-017-2122-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2122-z