Abstract

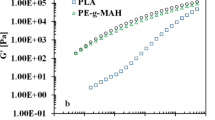

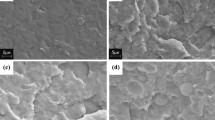

Attempts were made to study the effect of reactive compatibilization via Friedel–Crafts alkylation reaction, using AlCl3 as a catalyst, on rheology, morphology, and mechanical properties of polyethylene/polystyrene (PE/PS) blends. The results of linear viscoelastic measurements in conjunction with the results of the mixing torque variation indicated that PS showed much more degradation than that of PE in the presence of AlCl3. It was also found that while for PE-rich blends, the viscosity, and storage modulus increased by reactive compatibilization, they decreased for PS-rich blends. The variation of viscosity and storage modulus for 50/50 blend was found to be dependent on frequency ranges showing the competitive effects of PE–g–PS copolymer formation and PS degradation. The results of morphological studies showed that reactive compatibilization decreased the particle size and particle-size distribution broadness because of in situ graft copolymer formation. Reactive compatibilization enhanced the tensile strength and elongation at break for PE-rich blends. It was demonstrated that there is a close interrelationship between rheology, morphology, and mechanical properties of reactive compatiblized PE/PS blends. It was also demonstrated that rheological behaviors have a reliable sensitivity to follow the structural and morphological changes during compatibilization process, so that, those information can be used to predict the morphology as well as mechanical properties of the blends.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Utracki LA (1998) Commercial polymer blends. Springer, New York

Utracki LA (1989) Polymer alloys and blends. Hanser, Munich

Bisio AT, Xantos M (1995) How to manage plastics waste: technology and market opportunities. Hanser, Munich

Utracki LA (1991) Two-phase polymer systems. Hanser, Munich

Wu S (1982) Polymer interfaces and adhesion. Marcel Dekker, New York

Milner S, Xi H (1996) How copolymers promote mixing of immiscible homopolymers. J Rheol 40:663–687

Favis BD (2000) Factors influencing the morphology of immiscible polymer blends in melt processing. In: Paul DR, Bucknall CB (eds) Polymer blends, vol 1. Wiley, New York, pp 501–535

Fayt R, Jerome R, Teyssie P (1982) Molecular design of multicomponent polymer systems. III: Comparative behavior of pure and tapered block copolymers in emulsification of blends of low-density polyethylene and polystyrene. J Polym Sci 20:2209–2217

Fayt R, Jerome R, Teyssie P (1982) Molecular design of multicomponent polymer systems XIV: control of the mechanical properties of polyethylene–polystyrene blends by block copolymers. J Polym Sci 27:775–793

Fayt R, Jerome R, Teyssie P (1987) Characterization and control of interfaces in emulsified incompatible polymer blends. Polym Eng Sci 27:328–334

Utracki LA, Sammut P (1990) On the uniaxial extensional flow of polystyrene/polyethylene blends. Polym Eng Sci 30:1019–1026

Lindsay CR, Paul DR, Barlow JW (1981) Mechanical properties of HDPE–PS–SEBS blends. J Appl Polym Sci 26:1–8

Schwarz MC, Keskkula H, Barlow JW, Paul DR (1988) Deformation behavior of HDPE/(PEC/PS)/SEBS blends. J Appl Polym Sci 35:653–677

Guo HF, Packirisamy S, Mani RS, Aronson CL, Gvozdic NV, Meier DJ (1998) Compatibilizing effects of block copolymers in low-density polyethylene/polystyrene blends. Polymer 39:2495–2505

Xu SA, Tjong SC (2000) Deformation mechanisms and fracture toughness of polystyrene/high-density polyethylene blends compatibilized by triblock copolymer. J Appl Polym Sci 77:2024–2033

Macaubas PHP, Demarquette NR (2001) Morphologies and interfacial tensions of immiscible polypropylene/polystyrene blends modified with triblock copolymers. Polymer 42:2543–2554

Jianming L, Ma PL, Favis BD (2002) The role of the blend interface type on morphology in Co-continuous polymer blends. Macromolecules 35:2005–2016

Simmons A, Baker W (1989) Basic functionalization of polyethylene in the melt. Polym Eng Sci 29:1117–1123

Baker W, Saleem M (1987) Polystyrene-polyethylene melt blends obtained through reactive mixing process. Polym Eng Sci 27:1634–1641

Liu N, Baker W, Russell K (1990) Functionalization of polyethylenes and their use in reactive blending. J Appl Polym Sci 41:2285–2300

Sun Y, Flaris V, Baker W (1997) Evaluation and characterization of vector fluids and peroxides in a process of in situ compatibilization of polyethylene and polystyrene. The Can J Chem Eng 75:1153–1158

Lagardere P, Baker W (1998) Mechanical properties and morphology of copolymer modified polymer blends. Polymer 56:198–202

Morrison R. T, Boyd R. N (1973) Electrophilic Aromatic Substitution. In: Organic Chemistry, Allyn and Bacon, New York, pp 337-371

Reinhard B (2002) Substitution reactions on aromatic compounds. In: Advanced organic chemistry, Harcourt/Academic Press, San Diego, pp 169–217

Carrick WL (1970) Reactions of polyolefins with strong lewis acids. J Polym Sci A 8:215–223

Barentsen WM, Heikens D (1973) Mechanical properties of polystyrene/low density polyethylene blends. Polymer 14:579–583

Heikens D, Barentsen W (1977) Particle dimensions in polystyrene/polyethylene blends as a function of their melt viscosity and of the concentration of added graft copolymer. Polymer 18:69–72

Sun Y, Baker WE (1997) Polyolefin/polystyrene in situ compatibilization using Friedel–Crafts alkylation. J Appl Polym Sci 65:1385–1393

Sun Y, Willemse RJG, Liu TM, Baker WE (1998) In situ compatibilization of polyolefin and polystyrene using Friedel–Crafts alkylation through reactive extrusion. Polymer 39:2201–2208

Gao Y, Huang H, Yao Z, Shi D, Ke Z, Yin J (2003) Morphology, structure, and properties of in situ compatibilized linear low-density polyethylene/polystyrene and linear low-density polyethylene/high-impact polystyrene blends. J Polym Sci B 41:1837–1849

Diaz MF, Barbosa SE, Capiati NJ (2002) Polyethylene–polystyrene grafting reaction: effects of polyethylene molecular weight. Polymer 43:4851–4858

Diaz MF, Barbosa SE, Capiati NJ (2007) Reactive compatibilization of PE/PS blends: effect of copolymer chain length on interfacial adhesion and mechanical behavior. Polymer 48:1058–1065

Pukanszky B, Kennedy JP, Kelen T, Tudos F (1981) Cationic reactions in the melt 1. The effect of Lewis acids on polystyrene. Polym Bull 5:469–476

Graebling D, Benkira A, Gallot Y, Muller R (1994) Dynamic viscoelastic behaviour of polymer blends in the melt—experimental results for PDMS/POE-DO, PS/PMMA and PS/PEMA blends. Eur Polym J 30:301–308

Germain Y, Ernest B, Genelot O, Dhamani L (1994) Rheological and morphological analysis of compatibilized polypropylene/polyamide blends. J Rheol 38:681–697

Graebling D, Muller R, Palierne JF (1993) Linear viscoelastic behavior of some incompatible polymer blends in the melt, interpretation of data with a model of emulsion of viscoelastic liquids. Macromolecules 26:320–329

Gramespacher H, Meissner J (1992) Interfacial tension between polymer melts measured by shear oscillations of their blends. J Rheol 36:1127–1141

Lacroix C, Grmela M, Carreau PJ (1998) Relationships between rheology and morphology for immiscible molten blends of polypropylene and ethylene copolymers under shear flow. J Rheol 42:41–62

Utracki LA (1991) On the viscosity-concentration dependence of immiscible polymer blends. J Rheol 35:1615–1638

Jorgensen L, Utracki L (1991) Dual phase continuity in polymer blends. Makromol Chem, Macromol Symp 48–49:189–209

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahbazi, K., Razavi Aghjeh, M.K., Abbasi, F. et al. Rheology, morphology and tensile properties of reactive compatibilized polyethylene/polystyrene blends via Friedel–Crafts alkylation reaction. Polym. Bull. 69, 241–259 (2012). https://doi.org/10.1007/s00289-012-0751-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-012-0751-9