Abstract

Antifungal peptides (AFPs) can be used as novel preservatives, but achieving large-scale production and application remains a long-term challenge. In this study, we developed a hybrid peptide MD (metchnikowin-drosomycin fusion) secreted into Escherichia coli supernatant, demonstrating strong inhibitory activity against Aspergillus flavus and Botrytis cinerea. The fusion tag did not impact its activity. Moreover, an endotoxin-free and oxidative leaky strain was developed by knocking out the trxB, gor, and lpp genes of endotoxin-free E. coli ClearColi-BL21(DE3). This strain facilitates the proper folding of multi-disulfide bond proteins and promotes the extracellular production of recombinant bioactive AFP MD, achieving efficient production of endotoxin-free MD. In addition, temperature control replaces chemical inducers to further reduce production costs and circumvent the toxicity of inducers. This extracellularly produced MD exhibited favorable effectiveness in inhibiting fruit mold growth, and its safety was preliminarily established by gavage testing in mice, suggesting that it can be developed into a green and sustainable fruit fungicide. In conclusion, this study provides novel approaches and systematic concepts for producing extracellularly active proteins or peptides with industrial significance.

Key points

• First report of extracellular production of bioactive antifungal peptide in Escherichia coli.

• The hybrid antifungal peptide MD showed strong inhibitory activity against Aspergillus flavus and Botrytis cinerea, and the activity was not affected by the fusion tag.

• Endotoxin-free oxidative Escherichia coli suitable for the expression of multi-disulfide bond proteins was constructed.

Similar content being viewed by others

Introduction

Grains, feed, fruits, and vegetables are susceptible to infection by Aspergillus flavus or Botrytis cinerea throughout their storage (Wang et al. 2019). Currently, chemical fungicides, including iprodione, pyrimethanil, and procymidone, are still primary preventative agents against mold growth (González-Domínguez et al. 2019). However, the long-term use of these chemicals has resulted in a group of serious consequences, including enhanced pathogen resistance, serious soil pollution, and the deterioration of ecological structure (Bu et al. 2021). Therefore, there is an urgent requirement for a new class of high-efficiency, low-toxicity fungicides to improve this situation. In recent years, several research groups have developed antifungal peptides (AFPs) capable of inhibiting the growth of pathogenic fungi as preservatives for feed, fruits, and meat products (Ramos-Martín et al. 2022; Thery et al. 2019). Dou et al. (2021) identified that epsilon-poly-L-lysine could inhibit mycelial growth and spore germination of Penicillium expansum, and it has an inhibitory effect on the P. expansum-mediated blue mold of apples, which has promising applications in managing postharvest fungal diseases in fruits. Lima et al. (2021) reported that synthetic peptides significantly controlled Penicillium digitatum infection in oranges, which have a high potential to be used as novel preservatives to control fruit infection by P. digitatum.

Exogenous expression of AFPs in Escherichia coli via genetic engineering is an effective method to develop novel mold inhibitors to resolve fungal infection problems (Wang et al. 2010a, 2010b; Yuan et al. 2007). For instance, the antimicrobial peptides (AMPs) drosomycin and metchnikowin can inhibit filamentous fungi and Gram-positive bacteria and fungi, respectively, but do not inhibit E. coli, and are therefore very suitable for recombinant expression in E. coli (Fehlbaum et al. 1994; Levashina et al. 1995). However, AMPs have low molecular weight and commonly must be expressed with a fusion tag to promote solubility (Luan et al. 2014; Park et al. 2021), which requires further purification and processing to unlock their biological activity. However, the resultant complex purification processes and elevated costs of intracellular AFP production mean that it is challenging to achieve a large-scale application (Yu et al. 2015). Therefore, simplifying the purification process to the maximum extent while ensuring the good activity of AFPs is a challenge for industrial production and application of AFPs.

Extracellular production of AFPs may improve their solubility and stability, while alleviating the metabolic burden of the host (Ding et al. 2019). Concomitantly, extracellular AFPs can evade degradation by intracellular proteases, which is of great benefit to the purity and yield of AFPs (Choi and Lee 2004; Majander et al. 2005). However, under common culture conditions in LB medium at 37 °C, the secretion of proteins in the E. coli expression system is poor (Yu et al. 2015). Therefore, we endeavored to establish a secretory expression system suitable for the production of AFPs alongside other exogenous recombinant proteins in E. coli via a series of molecular modifications.

Ultimately, the purpose of this study is to produce biologically active AFPs in an inexpensive and efficient way outside of E. coli via gene editing and replacement of expression elements, with a view to developing ecologically responsible and sustainable antifungal agents. Additionally, this study proposed new insights and methodologies for the manufacturing of high-value exogenous proteins or peptides within E. coli.

Materials and methods

Bacterial strains and plasmids

The E. coli DH5α (Genestar, Beijing, China) and ClearColi BL21 (DE3) strains (Lucigen, Middleton, WI, USA) were utilized as host cells for cloning and genetic modification, respectively. The Origami (DE3) (YouBio, Changsha, China) and ClearColi BL21 (DE3) strains were employed as host cells for protein expression. The plasmids pET28a-SUMO, pET22b, and pBV220 were employed to ligate exogenous genes for the expression of target proteins (Zhang et al. 2016). The plasmids pTargetF and pCas were utilized for gene deletion in the E. coli genome (Jiang et al. 2015). All strains and plasmids used in this study are shown in Supplemental Table S1.

Construction of recombinant plasmids

All recombinant expression plasmids were generated using enzymatic digestion and ligation. Among these plasmids, the constructed intracellular expression plasmid was pET28a-SUMO-drosomycin. Plasmid pET22b (signaling peptide PelB replaced if necessary) and pBV220 were employed as a backbone vector to generate fusion expression plasmids for secretion of exogenous proteins.

Construction of hybrid AFPs

The DNAs for AFPs drosomycin, metchnikowin, and LsGRP1-c were artificially synthesized by Ruibiotech Co., LTD (Beijing, China). They were utilized as templates employing an overlap PCR technique to generate hybrid AFPs possessing a flexible linker (amino acid sequence: GGGGS) between two AFPs. The AFP genes for DM, MD (NCBI accession number: GenBank OR359291), DL, LD, ML, LM, ML, LM, DML, DLM, MLD, MDL, LMD, and LDM were acquired through hybrid mixtures of DNA sequences for drosomycin (D), metchnikowin (M), and LsGRP1-c (L) in different combinations. The schematic diagram outlining the overlap PCR for hybrid AFPs constructions is shown in Supplemental Fig. S1. Amino acid and DNA sequences of antifungal peptides and signal peptides employed in this study are illustrated in Supplemental Table S2 and S3. The primers used for amplifying genes of hybrid AFPs are outlined in Supplemental Table S4.

Protein overexpression

Luria-Bertani (LB) medium containing 10 g/L tryptone, 5 g/L NaCl, and 5 g/L yeast extract was employed (1.5% agar was added in solid medium) for seed culture and protein overexpression. The final concentrations of kanamycin and ampicillin utilized in the medium were 50 μg/mL and 100 μg/mL, respectively. Recombinant E. coli cells were cultured at 37 °C [for pET22b of isopropyl β-D-thiogalactoside (IPTG)-inducible expression vector] or 30 °C (for pBV220 of temperature-inducible expression vector), with shaking at 220 rpm for 12 h, and then inoculated in a shake flask with LB medium (100 mL/250 mL) at a percentage of 1% (vol/vol) and cultured until the OD600 reached 0.6. Recombinant protein expression was induced using either 0.5 mM IPTG or temperature shift to 42 °C.

High-density fermentation of hybrid AFP MD was processed in a 5 L fermenter (Bxbio, Shanghai, China). The recombinant strain was cultured in 2 L of LB medium. Subsequently, 300 g/L fructose was added into the medium after glucose was consumed for approximately 9 h. During fermentation, the pH of the medium was adjusted to 8.0 using ammonia, the dissolved oxygen concentration was controlled to be above 30% by adjustment of the airflow and rotation speed, and the temperature was controlled at 30 °C. When the OD600 reached 10, expression was induced by shifting the temperature to 42 °C.

Protein sample preparation

Intracellular proteins were purified through affinity chromatography. Specifically, 100 mL culture was extracted after 8 h of induced expression and centrifuged at 12,000 × g (Hitachi CR22G II, Tokyo, Japan) for 60 min at 4 °C. The intracellular protein within the cell precipitate (resuspended in lysis buffer: 20 mM Tris-HCl pH 8.0, 10 mM imidazole, 150 mM NaCl) was extracted using ultrasonication, and the supernatant was acquired through centrifugation at 20,300 × g (Hitachi CR22G II, Tokyo, Japan) for 1 h. The supernatant was passed through a 0.22 μm filter (Millipore, Billerica, MA, USA) and loaded onto a 5 mL Ni NTA column (Smart-Lifesciences, Changzhou, China). Following washes with wash buffer (20 mM Tris-HCl pH 8.0, 20 mM imidazole, 150 mM NaCl), elution was performed using elution buffer (20 mM Tris-HCl pH 8.0, 250 mM imidazole, 150 mM NaCl). Desalting and buffer exchange (final buffer 20 mM Tris-HCl pH 8.0, 150 mM NaCl) were carried out using a 10 kDa ultrafiltration concentration tube (Millipore, Billerica, MA, USA). Protein concentration was quantified using a commercial BCA protein assay kit (CWBio, Taizhou, China) following the manufacturer’s instructions prior to an antifungal activity assay.

To determine the amount of extracellular and intracellular proteins, 1 mL of recombinant E. coli cultures at different induction times were centrifuged at 16,000 × g (Eppendorf centrifuge 5424, Hamburg, Germany) for 10 min at 4 °C. The supernatant was passed through a 0.22 μm filter and used for the determination of extracellular proteins as well as antifungal activity. The precipitate was resuspended in 100 μL of 1 × loading buffer [50 mM Tris–HCl pH 6.8, 2% SDS (sodium dodecyl sulfate), 0.1% BPB (brom-chlorphenol blue), 10% glycerin, 50 mM DTT (dithiothreitol)] and employed for determination of intracellular proteins. A 15% SDS-PAGE was then conducted to analyze extracellular (20 μL) and intracellular (10 μL) protein expression following denaturation at 95 °C for 10 min.

Extracellular proteins were purified using ion exchange chromatography (Q-HP, GE Healthcare, Little Chalfont, UK). Specifically, 100 mL of the culture was collected following 24 h of induced expression and centrifuged at 12,000 × g (Hitachi CR22G II, Tokyo, Japan) for 60 min at 4 °C. Desalting and buffer exchange (final buffer: 20 mM Tris-HCl pH 8.0, 150 mM NaCl) of the extracellular protein were carried out using a 10 kDa ultrafiltration concentration tube (Millipore, Billerica, MA, USA). After loading onto a Q-HP column, elution buffer B (20 mM Tris-HCl pH 8.0, 1 M NaCl) was used to elute the target protein. A 15% SDS-PAGE was then conducted for analysis of the protein samples from each UV peak.

Gene deletion

The deletion of trxB, gor, lpp, hslV, and clpP genes in E. coli was accomplished using the CRISPR-Cas9 system with plasmids pTargetF and pCas (Jiang et al. 2015). Specifically, the N20 sequence of sgRNA was designed using a web-based tool (http://crispor.tefor.net/) and ligated into the plasmid pTargetF. Donor DNA employed for homologous recombination was constructed as follows: the region 500 bp upstream and 500 bp downstream of the target gene were amplified through PCR using the E. coli ClearColi BL21 (DE3) genome DNA as a template. This product was then ligated using overlapping PCR. The plasmid pCas was transformed into ClearColi BL21 (DE3) competent cells. A positive clone was grown in LB medium containing 50 μg/mL kanamycin until an OD600 of 0.25 was reached. 100 mM L-arabinose was added to induce the expression of Cas9 and homologous recombinase (Gam, Beta, and Exo) at 30 °C. When the OD600 reached approximately 0.6, ClearColi BL21 (DE3) electrocompetent cells containing the pCas plasmid were prepared, following the method described by Jiang et al. (2015). The donor DNA (600–800 ng) and pTargetF plasmid containing the sgRNA (400 ng) were electroporated (1.0 mm cuvette, 1.8 kV, 10 μF, 600 Ω) into the above electrocompetent cells. After recovery at 30 °C for 3 h, the cells were spread onto LB agar plates supplemented with spectinomycin (50 μg/mL) and kanamycin (50 μg/mL) and cultured overnight at 30 °C. Positive clones were identified through PCR and DNA sequencing. Finally, a gene-deleted clone was grown in LB medium containing 50 μg/mL kanamycin and 0.5 mM IPTG and cultured overnight at 30 °C to eliminate the plasmid pTargetF. The plasmid pCas was then removed on LB medium overnight at 42 °C. Additionally, screening of a trxB and gor gene-double-knockout strain was conducted, following a method reported by Faulkner et al. (2008).

Antifungal activity assay

A. flavus NRRL 3357, B. cinerea B05.10, and Fusarium graminearum ACCC 37687 were cultured in PDA medium at 30 °C for 5 days. Their spores were obtained by washing the surface of the medium with 5 mL of sterile water, and the mycelium was separated by filtration through 8 layers of sterile gauze. The number of spores was determined using a hemacytometer and diluted to 1 × 107 CFU (colony forming units) /mL. The AFPs were supplemented to PDA solid medium at a final indicated concentration. After solidification, 1 × 105 CFU of fungal spore suspension was included on the middle of the plate, and fungal growth was observed for 72 h at 30 °C. To observe the effect of AFP on the growth of fungal mycelium, A. flavus NRRL 3357 was grown on PDA medium at 30 °C for 3 days. A diameter of approximately 0.5 cm of A. flavus was cut out from the culture using a hole punch and placed onto a new PDA plate for growth at 30 °C until a colony size of 2 cm was observed. Following this, PBS, SUMO-drosomycin, and drosomycin were carefully supplemented around the perimeter. The agar plate was cultured for 12–18 h at 30 °C to observe the mycelial growth.

To assess the feed mold growth, 4 mL of purified recombinant protein (0.25 mg/mL) or 8 mL of extracellular supernatant from hybrid AFPs was added to 10 g of feed (corn-soybean meal basal diet). After thorough mixing, the feed was placed in a cool location at room temperature and observed for mold growth. In our fruit mold growth assay, 5 mL of AFP expression supernatant was sprayed onto fresh fruits (all purchased from a supermarket on the morning of the experiment), while fruits in the control group were sprayed with 5 mL of sterile LB medium. After natural air-drying, the fruits were placed into a freshness protection package (only one fruit per package) and stored in a cool location at room temperature to observe the mold growth on these fruits.

Stability of antifungal activity

The effect of temperature on the antifungal activity of hybrid AFP MD was examined as described previously (Fan et al. 2023). Specifically, MD was placed at 40, 50, 60, 70, 80, 90, or 100 °C for 15 min in a controlled water bath (DK-8AXX, Yiheng, Shanghai, China), and incubation at room temperature was utilized as a control. Following cooling and centrifugation, the antifungal activity of MD was assessed as described above.

Animals and design of in vivo experiments

This study was conducted following the provisions of the Institutional Animal Care and Use Committee of China Agricultural University issued rules for laboratory Animals-Guideline of Welfare and Ethics of China (ICS 65.020.30). The protocol used in this study was approved by the same institution.

Male BALB/c mice (3–4 weeks) used in this study were purchased from SPF Biotechnology Co., Ltd. (Beijing, China). All mice were individually housed in a laminar flow cabinet in the same humidity- and temperature-controlled room on a 12 h light and 12 h dark cycle. All mice had access to distilled water and sterilized conventional feed ad libitum during the treatment period. Prior to the experiment, 60 mice were randomly assigned to 4 groups (15 mice in each group across 20 cages), after the 3-day equilibration period, in which the 4 groups were administered a daily gavage of 0.2 mL of LB medium (control group) or 6.25 (LMD), 12.5 (MMD), and 25 (HMD) mg/kg (mg per kg body weight [BW]) of MD, respectively. The dosages of MD were calculated based on the above antifungal activity assay. The treatment was conducted for 14 days until the mice were euthanized.

Sample collection and measurements

On days 0 and 4, all mice were weighed individually. Feed loss was recorded in each cage simultaneously. These values were used to assess performance, including average daily gain (ADG), average daily feed intake (ADFI), and feed efficiency (Feed: Gain). The survival rate was monitored over 14 days.

At the conclusion of the experiment, blood was collected from the eyes and allowed to equilibrate at room temperature for 30 min. It was then centrifuged at 4000 × g (Eppendorf centrifuge 5424, Hamburg, Germany) for 30 min, and the serum was obtained and stored at −20 °C for serum biochemical index analyses. Mice were euthanized, and their heart, liver, spleen, lungs, and kidneys were isolated and weighed to determine organ coefficient (organ coefficient = organ weight/body weight × 100%).

Statistical analysis

The MIXED procedure of SAS 9.4 (SAS Institute Inc., Cary, NC, USA) was used for variance analysis across all data. The analysis of growth performance was conducted on each cage, and the analysis of other data was based on individual mice. Tukey’s Multiple Range Test was used to measure the statistical differences between groups. Significance was defined as P < 0.05.

Results

The exogenous expressed AFP drosomycin in E. coli has antifungal activity

Drosomycin is an AFP derived from Drosophila melanogaster, which inhibits filamentous fungi (Fehlbaum et al. 1994). Its molecular weight is 4.9 kDa, and it contains four disulfide bonds. To obtain drosomycin with biological activity in E. coli, we constructed the recombinant plasmid pET28a-SUMO-drosomycin and expressed it alongside the SUMO tag. Following affinity chromatography purification and SUMO protease Ulp1 digestion, drosomycin was obtained with more than 85% purity, and its yield was approximately 30 mg/L (Supplemental Fig. S2A). Purified drosomycin possessed an inhibitory activity against the growth of A. flavus NRRL 3557 spores and mycelium, as well as an inhibitory effect on feed mold growth, while the fusion protein did not (Supplemental Fig. S2B-D). These data suggest that the AFP drosomycin produced in E. coli has sufficient antifungal activity and the potential to be used as a preservative.

Extracellular production of the AFP drosomycin in E. coli

Complex purification processes and the high production cost of intracellular expression in E. coli hinder the extensive application of drosomycin. Therefore, we aimed to construct an extracellular expression system for drosomycin to simplify purification. We first attempted to investigate the effect of various signal peptides and carrier proteins on the extracellular production of drosomycin. However, signal peptides related to the Sec pathway (Choi and Lee 2004) including AnsBII, endolanase, LamB, L-asparaginase II, LPP, LTB, PhoA, PhoE, PelB, OmpA, OmpF, and MalE, as well as carrier proteins including PelB-Cherry (Wu et al. 2013), eYebF and sYebF (Haitjema et al. 2014) were unable to mediate drosomycin’s extracellular production (data not shown). Following several attempts, we identified two signal peptides, SX and OT, that could mediate the extracellular production of fused drosomycin (Supplemental Fig. S3A), and the secretion efficiency of SX was improved compared to OT.

To improve the yield of drosomycin, we tested various fusion tags (Ki and Pack 2020). As shown in Supplemental Fig. S3B, drosomycin fused with SUMO tag and the signal peptide SX exhibited the optimal secretion efficiency and expression yield. The secretion efficiency of mCherry, Cherry, and Fh8 tags was limited, and there were more un-secreted proteins in the cytoplasm, while GST and eGFP tags significantly impacted the expression of drosomycin. Ultimately, the maximum extracellular production of the AFP drosomycin was achieved through the application of SX and OT signal peptides (especially SX) as well as the fusion tag SUMO.

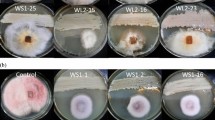

Screening of biological active hybrid AFPs

As anticipated, the SUMO tag inhibited the antifungal activity of secreted AFP (Supplemental Fig. S2). To overcome this obstacle, we carried out a small-scale screening for hybrid AFPs. Twelve hybrid AFPs were generated through overlap PCR using drosomycin, metchnikowin, and LsGRP1-c as parent peptides. These hybrid AFPs were produced extracellularly via the above-established secretory expression system (Fig. 1A), and the antifungal effect of their supernatant was examined through a feed mold growth assay. As shown in Fig. 1B, across all tested hybrid AFPs, only MD exhibited a strong inhibitory effect on feed mold growth. Further examination demonstrated that MD could completely prevent the growth of B. cinerea B05.10 (Fig. 2A and D) and A. flavus NRRL 3557 (Fig. 2B and E) within 72 h when the concentration was 25 mg/L and result in a 50% inhibition of F. graminearum ACCC 37687 (Fig. 2C and F) at a concentration of 25 mg/L. To exclude the antifungal effect of other supernatant components, we used ion exchange chromatography to purify MD (Fig. 3A and B). As shown in Fig. 3C, we determined that the growth inhibition effect of high-purity MD (> 85%) was similar to that of unpurified MD on A. flavus NRRL 3557. These findings suggested that we screened a hybrid AFP MD with a notable effect on fungal control, and its antifungal activity was not impacted greatly by the SUMO tag.

Extracellular production and activity identification of hybrid antifungal peptides. A SDS-PAGE analysis of extracellular and intracellular protein samples of recombinant hybrid antifungal peptides expressed in E. coli Origami (DE3) after 24 h of induction expression; B Appearance of feed mold production test at d 4; D, drosomycin; M, metchnikowin; L, LsGRP1-c

Construction of an endotoxin-free oxidative leaky E. coli strain expressing AFPs

Lipopolysaccharide, known as endotoxin, is a unique component in the outer membrane of Gram-negative bacteria (Cardoso et al. 2022). It is often made up of three parts: polysaccharide O antigen, core oligosaccharides, and hydrophobic lipid A. Of these components, lipid A immobilizes LPS on the outer membrane and acts as an agonist for toll-like receptor 4/myeloid differentiation factor 2-mediated pro-inflammatory activity in mammals (Schneier et al. 2020). The recombinant proteins expressed in E. coli are often contaminated with LPS (Mamat et al. 2015). If not eliminated, the final biological products will be unsafe for animals or humans. Currently, endotoxins may be removed through several chromatographic methods, but these are expensive and complex, with total removal being challenging (Mamat et al. 2015). Therefore, Mamat et al. (2015) developed an endotoxin-free recombinant expression strain known as ClearColi-BL21(DE3) through rational editing of the outer membrane biosynthetic pathway of E. coli. The ClearColi-BL21(DE3) cells possess a modified LPS known as lipid IVA, which lacks the polysaccharide chains as well as the two acyl chains, and, therefore, does not result in endotoxic reactions in humans (Cardoso et al. 2022).

To eliminate the adverse effects of endotoxin on the downstream application of MD, we employed endotoxin-free E. coli ClearColi-BL21(DE3) for the expression of AFPs. As illustrated in Fig. 4A, MD was produced extracellularly, but compared with oxidative E. coli Origami (DE3) (Faulkner et al. 2008), there was an apparent miscellaneous protein band. We speculated that this may be caused by misfolding of MD with four disulfide bonds. To examine this hypothesis, we knocked out one or both of two key reductase genes (trxB and gor) in the ClearColi-BL21(DE3) strain using the Crispr/Cas9 gene editing technique. In the ClearColi-BL21(DE3)-ΔtrxB/gor strain, the F38 site of the peroxiredoxin family member ahpC protein was lacking (Fig. 4B). This gain-of-function mutation enhances its reducing ability and assists in maintaining typical cell viability, consistent with the reports from Lobstein et al. (2012). The expression results in Fig. 4C indicated that although the trxB gene single knockout strain increased the extracellular expression level of MD, neither a trxB nor a gor gene single knockout strain could limit the misfolding of MD in the ClearColi-BL21 (DE3) cells. However, the double knockout of trxB and gor genes almost completely eliminated the misfolded MD while increasing the extracellular expression of MD by about 1.5-fold (Fig. 4C). However, there were several correctly folded un-secreted proteins in the cytoplasm of the double knockout strain (Fig. 4C), and further experiments were required to improve the secretion efficiency.

Extracellular production of hybrid antifungal peptide MD in endotoxin-free oxidative ClearColi BL21 (DE3). A SDS-PAGE analysis of MD after 24 h of induction expression in ClearColi BL21 (DE3), 1: Origami (DE3), 2: BL21 (DE3), 3: ClearColi BL21 (DE3); B Comparison of amino acid sequences of ahpC protein in ClearColi BL21 (DE3) WT and ClearColi BL21 (DE3)-ΔtrxB/gor strains; C SDS-PAGE analysis of MD after 24 h of induction expression in different ClearColi BL21 (DE3) strains, 1: Origami (DE3), 2: ClearColi BL21 (DE3), 3: ClearColi BL21 (DE3)-ΔtrxB, 4: ClearColi BL21 (DE3)-Δgor, 5: ClearColi BL21 (DE3)-ΔtrxB/gor; D SDS-PAGE analysis of MD after 24 h of induction expression in ClearColi BL21 (DE3)-ΔtrxB/gor/lpp strain, 1: Origami (DE3), 2: ClearColi BL21 (DE3)-ΔtrxB/gor, 3: ClearColi BL21 (DE3)-ΔtrxB/gor/lpp; black arrows: the correctly folded MD; red arrows: the misfolded MD

Deleting genes related to cell membranes or cell wall synthesis to construct leaky E. coli strains has become an effective strategy for improving the extracellular production of recombinant proteins (Chen et al. 2014). Among them, the knockout of the outer membrane lipoprotein lpp (Braun’s lipoprotein) gene has little effect on bacterial strain growth (Fu et al. 2022), while it significantly promotes the leakage of recombinant proteins (Chen et al. 2014). Therefore, we knocked out the lpp gene of the ClearColi BL21(DE3)-ΔtrxB/gor strain to enhance the secretion efficiency of MD. The intracellular recombinant protein was almost entirely secreted into the supernatant, and the secretory expression was improved by nearly 2-fold. This may be due to the knockout of the lpp gene, which increased the permeability of the outer membrane, promoting the leakage of the recombinant protein from the periplasm to the supernatant (Fu et al. 2022).

Construction of a temperature-inducible expression system

In developing commercial recombinant protein expression systems, when final products involve living organisms, in addition to lowering production costs, an important consideration is the safety of the products. Therefore, using expensive and toxic chemicals, such as IPTG, to induce the expression of recombinant AFP was not an ideal strategy (Liu et al. 2012). Considering the above concerns and the high-temperature resistance activity of MD (Fig. 5A), we attempted to use a different prokaryotic expression vector pBV220 using a λpR/pL-cI857 temperature-sensitive regulatory system (Zhang et al. 2016) to achieve MD expression via temperature regulation. Upon temperature shifting to 42 °C, MD was expressed successfully under the control of the temperature-sensitive promoter pR/pL and secreted into the supernatant (Fig. 5B). However, there was a clear miscellaneous protein band below the MD band, possibly due to the heat shock reaction of E. coli, resulting in the rapid synthesis of various heat shock proteins, including the ClpP and HslV proteases (Guisbert et al. 2008). Therefore, we knocked out clpP and hslV genes in ClearColi-BL21(DE3)-ΔtrxB/gor/lpp cells and found that knocking out the hslV gene resulted in greater improvement than knocking out clpP, resulting in significantly reduced miscellaneous protein observation (Fig. 5C).

Construction of temperature-inducible expression system of hybrid antifungal peptide MD. A Effect of temperature on the activity of MD; B SDS-PAGE analysis of MD after 24 h of temperature-inducible expression in different ClearColi BL21 (DE3) strains, 1: ClearColi BL21 (DE3), 2: ClearColi BL21 (DE3)-ΔtrxB, 3: ClearColi BL21 (DE3)-Δgor, 4: ClearColi BL21 (DE3)-ΔtrxB/gor, 5: ClearColi BL21 (DE3)-ΔtrxB/gor/lpp; C SDS-PAGE analysis of MD after 24 h of temperature-inducible expression in different ClearColi BL21 (DE3) strains, 1: ClearColi BL21 (DE3)-ΔtrxB/gor/lpp, 2: ClearColi BL21 (DE3)-ΔtrxB/gor/lpp/hslV, 3: ClearColi BL21 (DE3)-ΔtrxB/gor/lpp/clpP; D SDS-PAGE analysis of MD after different times of temperature-inducible expression at a 5 L fermenter for batch-feed fermentation; black arrows: MD; red arrows: the miscellaneous protein

To further expand the production scale of MD and modulate culture conditions more accurately, we utilized a 5 L fermenter for fed-batch fermentation. The bacteria were cultured at 30 °C to an OD600 of 10, and the temperature was altered to 42 °C to induce expression. Our findings demonstrated that the extracellular expression level could reach 500 mg/L after 24 h, and the secretion level was improved compared to shake flasks (Fig. 5D), suggesting its potential for large-scale production.

Application of MD in fruit preservation

Due to the high selectivity, effectiveness, tolerance, and lack of fungal resistance to AFPs as antifungal drugs (Fernández de Ullivarri et al. 2020), researchers have devoted great interest and attention to AFPs as novel biological drugs for the prevention and treatment of fungal infections (Nicola et al. 2019). Based on previous studies, B. cinerea, A. flavus, and F. graminearum, which could be inhibited by MD, are the primary postharvest fungal pathogens of most fruits and crops (Mohammed et al. 2023; Saif et al. 2021; Zhang et al. 2022). Therefore, we examined the inhibitory effect of MD on fruit mold growth. Our findings (Fig. 6) indicated that MD could limit the mold growth of corn, peach, pear, kiwifruit, and banana, while prolonging the storage period of several fruits, especially kiwifruit and banana (Fig. 6D and E). Next, we evaluated the safety of MD through intragastric administration to mice at different doses. As shown in Supplemental Table S5–S7, the hybrid AFP MD exhibited appropriate safety and did not result in weight loss, organ loss, or liver and kidney dysfunction in mice. These results demonstrate that MD is a promising, safe, and environmentally friendly product that has great application value in the control of postharvest decay in fruits.

Discussion

Several valuable proteins, including ApoA-1 and Hsp70, have been successfully expressed in ClearColi-BL21(DE3) (Mamat et al. 2015). However, the intracellular reducing environment can lead to the improper folding of multi-disulfide bond-containing proteins, limiting the production of multi-disulfide bond-containing proteins, such as MD, whose correct folding requires an oxidizing environment (Faulkner et al. 2008). In this study, we removed critical enzymes of the two reduction pathways and developed the oxidative ClearColi-BL21(DE3)-ΔtrxB/gor strain, enabling the MD containing four disulfide bonds to fold correctly and limiting the metabolic pressure on bacteria, thereby elevating the total expression level of the recombinant protein and broadening the application range of the strain. Moreover, by knocking out the lpp gene encoding the outer membrane lipoprotein, we enhanced the permeability of the outer membrane and improved the secretion efficiency of the recombinant protein.

In our study, we used two exogenous expression methods for the extracellular production of MD. Among them, the T7 expression system is the most widely employed expression system within E. coli, with high efficiency and high expression levels (Du et al. 2021). However, this method carries some disadvantages. For example, the use of IPTG to induce the expression of recombinant proteins increases production costs as well as the toxic risk posed by IPTG toward the final product (Dvorak et al. 2015). In the second temperature induction system, the secretory expression of hybrid AFP MD is induced only by increasing the temperature from 30 to 42 °C without adding an inducer, and the highest expression level observed was 500 mg/L, which is more suitable for industrial-scale production.

Infection by pathogenic fungi takes place before and after harvest throughout the growing season, often on mechanical wounds in fruits. The use of chemical fungicides (such as carbendazim, thiophanate-methyl, and imidazole) to inhibit or kill pathogenic microorganisms has a precise mechanism of action and high titer. In practical cases, these can significantly reduce the rot of fruits and vegetables caused by pathogenic infection and limit economic losses. It is a common and effective traditional method for controlling postharvest diseases (Calvo et al. 2007). However, the dependence on conventional chemical fungicides has resulted in various issues, such as the emergence of drug resistance in pathogenic fungi (Boubaker et al. 2009), the destruction of the ecological environment, especially the harm caused by fungicide residues on the health of consumers, attracting increasing attention from food science and technology workers as well as relevant national regulatory agencies (Tripathi and Dubey 2004). Sustainable agriculture, encompassing biological production and integrated crop management, demands the development of green alternatives to control postharvest fruit decay (Droby et al. 2016; Spadaro and Droby 2016). Fan et al. (2023) determined that marine AFP Epinecidin-1 could inhibit the growth of B. cinerea and limit the development of gray mold in postharvest peaches. In this study, we identified that hybrid AFP MD could hinder the growth of pathogenic fungi and delay natural mold growth on different kinds of fruits.

Our investigation screened a hybrid antifungal peptide MD whose activity was not impacted by the fusion tag. To ensure the effectiveness and safety of the final product, we developed an endotoxin-free oxidative E. coli suitable for the expression of multi-disulfide bond proteins through knockout of the two reductase genes of trxB and gor and achieved expression of endotoxin-free recombinant MD. The secretion efficiency of MD was improved by knocking out the lpp gene. Moreover, applying a temperature-induced expression system reduced the operation steps and saved production costs. A preliminary scale-up experiment was conducted in a 5 L fermenter using our optimized production system, and the extracellular expression level of MD was observed to be nearly 500 mg/L. The recombinant hybrid AFP MD exhibits sufficient application potential in the anti-mold growth of fruits, feed, and grains. In conclusion, we have developed a new type of hybrid AFP MD and systematically optimized its production system. The produced MD exhibits excellent antifungal ability, which promotes the development and industrialization of green, safe, and effective AFPs.

Data availability

Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

References

Boubaker H, Saadi B, Boudyach E, Aoumar AAB (2009) Sensitivity of Penicillium digitatum and P. italicum to imazalil and thiabendazole in Morocco. Plant Pathol J 8(4):152–158

Bu SW, Munir S, He PF, Li YM, Wu YX, Li XY, Kong BH, He PB, He YQ (2021) Bacillus subtilis L1–21 as a biocontrol agent for postharvest gray mold of tomato caused by Botrytis cinerea. Biol Control 157(2):104568

Calvo J, Calvente V, de Orellano ME, Benuzzi D, Sanz de Tosetti MI (2007) Biological control of postharvest spoilage caused by Penicillium expansum and Botrytis cinerea in apple by using the bacterium Rahnella aquatilis. Int J Food Microbiol 113(3):251–257

Cardoso VM, Paredes SAH, Campani G, Gonçalves VM, Zangirolami TC (2022) ClearColi as a platform for untagged pneumococcal surface protein A production: cultivation strategy, bioreactor culture, and purification. Appl Microbiol Biotechnol 106(3):1011–1029

Chen ZY, Cao J, Xie L, Li XF, Yu ZH, Tong WY (2014) Construction of leaky strains and extracellular production of exogenous proteins in recombinant Escherichia coli. Microb Biotechnol 7(4):360–370

Choi JH, Lee SY (2004) Secretory and extracellular production of recombinant proteins using Escherichia coli. Appl Microbiol Biotechnol 64(5):625–635

Ding N, Ruan Y, Fu X, Lin Y, Yu H, Han L, Fu C, Zhang J, Hu X (2019) Improving production of N-glycosylated recombinant proteins by leaky Escherichia coli. 3 Biotech 9(8):302

Dou Y, Routledge MN, Gong Y, Godana EA, Dhanasekaran S, Yang Q, Zhang X, Zhang H (2021) Efficacy of epsilon-poly-L-lysine inhibition of postharvest blue mold in apples and potential mechanisms. Postharvest Biol Technol 171:111346

Droby S, Wisniewski M, Teixidó N, Spadaro D, Jijakli MH (2016) The science, development, and commercialization of postharvest biocontrol products. Postharvest Biol Technol 122:22–29

Du F, Liu YQ, Xu YS, Li ZJ, Wang YZ, Zhang ZX, Sun XM (2021) Regulating the T7 RNA polymerase expression in E. coli BL21 (DE3) to provide more host options for recombinant protein production. Microb Cell Factories 20(1):189

Dvorak P, Chrast L, Nikel PI, Fedr R, Soucek K, Sedlackova M, Chaloupkova R, de Lorenzo V, Prokop Z, Damborsky J (2015) Exacerbation of substrate toxicity by IPTG in Escherichia coli BL21(DE3) carrying a synthetic metabolic pathway. Microb Cell Factories 14:201

Fan L, Wei Y, Chen Y, Jiang S, Xu F, Zhang C, Wang H, Shao X (2023) Epinecidin-1, a marine antifungal peptide, inhibits Botrytis cinerea and delays gray mold in postharvest peaches. Food Chem 403:134419

Faulkner MJ, Veeravalli K, Gon S, Georgiou G, Beckwith J (2008) Functional plasticity of a peroxidase allows evolution of diverse disulfide-reducing pathways. Proc Natl Acad Sci U S A 105(18):6735–6740

Fehlbaum P, Bulet P, Michaut L, Lagueux M, Broekaert WF, Hetru C, Hoffmann JA (1994) Insect immunity: septic injury of Drosophila induces the synthesis of a potent antifungal peptide with sequence homology to plant antifungal peptides. J Biol Chem 269(52):33159–33164

Fernández de Ullivarri M, Arbulu S, Garcia-Gutierrez E, Cotter PD (2020) Antifungal peptides as therapeutic agents. Front Cell Infect Microbiol 10:105

Fu LL, Sun MN, Wen WZ, Dong N, Li DF (2022) Extracellular production of Ulp1403-621 in leaky E. coli and its application in antimicrobial peptide production. Appl Microbiol Biotechnol 106(23):7805–7817

González-Domínguez E, Fedele G, Caffi T, Delière L, Sauris P, Gramaje D, Ramos-Saez de Ojer JL, Díaz-Losada E, Díez-Navajas AM, Bengoa P, Rossi V (2019) A network meta-analysis provides new insight into fungicide scheduling for the control of Botrytis cinerea in vineyards. Pest Manag Sci 75(2):324–332

Guisbert E, Yura T, Rhodius VA, Gross CA (2008) Convergence of molecular, modeling, and systems approaches for an understanding of the Escherichia coli heat shock response. Microbiol Mol Biol Rev 72(3):545–554

Haitjema CH, Boock JT, Natarajan A, Dominguez MA, Gardner JG, Keating DH, Withers ST, Delisa MP (2014) Universal genetic assay for engineering extracellular protein expression. ACS Synth Biol 3(2):74–82

Jiang Y, Chen B, Duan C, Sun B, Yang J, Yang S (2015) Multigene editing in the Escherichia coli genome via the CRISPR-Cas9 system. Appl Environ Microbiol 81(7):2506–2514

Ki MR, Pack SP (2020) Fusion tags to enhance heterologous protein expression. Appl Microbiol Biotechnol 104(6):2411–2425

Levashina EA, Ohresser S, Bulet P, Reichhart JM, Hetru C, Hoffmann JA (1995) Metchnikowin, a novel immune-inducible proline-rich peptide from Drosophila with antibacterial and antifungal properties. Eur J Biochem 233(2):694–700

Lima PG, Freitas CDT, Oliveira JTA, Neto NAS, Amaral JL, Silva AFB, Souza PFN (2021) Synthetic antimicrobial peptides control Penicillium digitatum infection in orange fruits. Food Res Int 147:110582

Liu J, Wang WD, Liu YJ, Liu S, Zhou B, Zhu LW, Ji X, Sun Y, Feng SZ (2012) Mice vaccinated with enteropathogenic Escherichia coli ghosts show significant protection against lethal challenges. Lett Appl Microbiol 54(3):255–262

Lobstein J, Emrich CA, Jeans C, Faulkner M, Riggs P, Berkmen M (2012) SHuffle, a novel Escherichia coli protein expression strain capable of correctly folding disulfide bonded proteins in its cytoplasm. Microb Cell Factories 11:56

Luan C, Zhang HW, Song DG, Xie YG, Feng J, Wang YZ (2014) Expressing antimicrobial peptide cathelicidin-BF in Bacillus subtilis using SUMO technology. Appl Microbiol Biotechnol 98(8):3651–3658

Majander K, Anton L, Antikainen J, Lång H, Brummer M, Korhonen TK, Westerlund-Wikström B (2005) Extracellular secretion of polypeptides using a modified Escherichia coli flagellar secretion apparatus. Nat Biotechnol 23(4):475–481

Mamat U, Wilke K, Bramhill D, Schromm AB, Lindner B, Kohl TA, Corchero JL, Villaverde A, Schaffer L, Head SR, Souvignier C, Meredith TC, Woodard RW (2015) Detoxifying Escherichia coli for endotoxin-free production of recombinant proteins. Microb Cell Factories 14:57

Mohammed K, Hassan B, Latifa A, Said E, Nabil R, Abdelaaziz F, Hajar EH, Abdessalem T, Essaid AB, Rachid L (2023) Bacillus cereus B8W8 an effective bacterial antagonist against major postharvest fungal pathogens of fruit. Postharvest Biol Technol 200:112315

Nicola AM, Albuquerque P, Paes HC, Fernandes L, Costa FF, Kioshima ES, Abadio AKR, Bocca AL, Felipe MS (2019) Antifungal drugs: new insights in research & development. Pharmacol Ther 195:21–38

Park AR, Kim SW, Kim SY, Kwon KC (2021) Expression of antimicrobial peptide (AMP), Cecropin B, in a fused form to SUMO tag with or without three-glycine linker in Escherichia coli and evaluation of bacteriolytic activity of the purified AMP. Probiotics Antimicrob Proteins 13(6):1780–1789

Ramos-Martín F, Herrera-León C, Antonietti V, Sonnet P, Sarazin C, D’Amelio N (2022) The potential of antifungal peptide Sesquin as natural food preservative. Biochimie 203:51–64

Saif FA, Yaseen SA, Alameen AS, Mane SB, Undre PB (2021) Identification and characterization of Aspergillus species of fruit rot fungi using microscopy, FT-IR, Raman and UV-Vis spectroscopy. Spectrochim Acta A 246:119010

Schneier M, Razdan S, Miller AM, Briceno ME, Barua S (2020) Current technologies to endotoxin detection and removal for biopharmaceutical purification. Biotechnol Bioeng 117(8):2588–2609

Spadaro D, Droby S (2016) Development of biocontrol products for postharvest diseases of fruit: the importance of elucidating the mechanisms of action of yeast antagonists. Trends Food Sci Technol 47:39–49

Thery T, Lynch KM, Arendt EK (2019) Natural antifungal peptides/proteins as model for novel food preservatives. Compr Rev Food Sci Food Saf 18(5):1327–1360

Tripathi P, Dubey NK (2004) Exploitation of natural products as an alternative strategy to control postharvest fungal rotting of fruit and vegetables. Postharvest Biol Technol 32(3):235–245

Wang CC, Yuan SS, Zhang WW, Ng T, Ye XJ (2019) Buckwheat antifungal protein with biocontrol potential to inhibit fungal (Botrytis cinerea) infection of cherry tomato. J Agric Food Chem 67(24):6748–6756

Wang LN, Yu B, Han GQ, He J, Chen DW (2010a) Design, expression and characterization of recombinant hybrid peptide attacin-thanatin in Escherichia coli . Mol Biol Rep 37(7):3495–3501

Wang Y, Jiang Y, Gong T, Cui X, Li W, Feng Y, Wang B, Jiang Z, Li M (2010b) High-level expression and novel antifungal activity of mouse beta defensin-1 mature peptide in Escherichia coli . Appl Biochem Biotechnol 160(1):213–221

Wu D, Lu Y, Huang H, Ma L, Che Y, Zha X, Yao B, Yang P (2013) High-level secretory expression of metchnikowin in Escherichia coli. Protein Expr Purif 91(1):49–53

Yu H, Li H, Gao D, Gao C, Qi Q (2015) Secretory production of antimicrobial peptides in Escherichia coli using the catalytic domain of a cellulase as fusion partner. J Biotechnol 214:77–82

Yuan Y, Gao B, Zhu S (2007) Functional expression of a Drosophila antifungal peptide in Escherichia coli. Protein Expr Purif 52(2):457–462

Zhang C, Qi J, Li Y, Fan X, Xu Q, Chen N, Xie X (2016) Production of α-ketobutyrate using engineered Escherichia coli via temperature shift. Biotechnol Bioeng 113(9):2054–2059

Zhang L, Zhou X, Li P, Wang Y, Hu Q, Shang Y, Chen Y, Zhu X, Feng H, Zhang C (2022) Transcriptome profile of Fusarium graminearum treated by putrescine. J Fungi (Basel) 9(1):60

Acknowledgements

Thank for Dr. Li Shan from Huazhong Agricultural University for providing plasmids and Xu Yong from Institute of Botany of the Chinese Academy of Sciences for valuable suggestions.

Funding

This work was supported by the National Natural Science Foundation of China (grant number 32172754) and the National Key Research and Development Program of China (grant number 2022YFC2105001).

Author information

Authors and Affiliations

Contributions

MS: investigation, software, formal analysis, writing—original draft and review; LF: methodology, validation, writing—original draft and review; TC: methodology; ND: conceptualization, methodology, writing—review and editing, supervision, project administration, funding acquisition.

Corresponding author

Ethics declarations

Ethical approval

All applicable international, national, and/or institutional guidelines for the care and use of animals were followed.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(PDF 541 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, M., Fu, L., Chen, T. et al. Extracellular production of antifungal peptides from oxidative endotoxin-free E. coli and application. Appl Microbiol Biotechnol 108, 56 (2024). https://doi.org/10.1007/s00253-023-12888-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00253-023-12888-4