Abstract

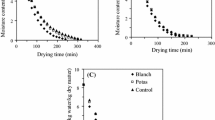

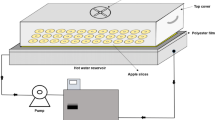

In this study, jujube slices were dried as thin-layers with thickness of 3 mm and 5 mm in the ranges of 50–90 °C of drying temperature in a convective dryer. The effect of temperature and slice thickness on the drying characteristics was analyzed. The increase of hot-air temperature and decrease of slices thickness shorted the drying time significantly. Drying rate curves indicated that all the process of drying taken place in the falling rate period. To select a suitable drying curve, seven thin-layer drying models were fitted to the experimental data. The Page model best described the drying behaviour of jujube scales with high correlation coefficient values. The effective diffusivity values changed from 0.72 × 10–9 to 3.45 × 10–9 m2/s within the given temperature range. Effective diffusivity increased with increasing temperature. An Arrhenius relation with activation energy values of 25.66 and 30.29 kJ/mol for the thickness of 3 and 5 mm, respectively. While L* value was in the range of 69.34 and 59.79, the a* value was ranged between –1.67 and 2.51 and the b* value between 16.10 and 24.21. The ascorbic acid content of jujube slices ranged from 3.71 mg AA/g DW to 5.23 mg AA/g DW, and the loss was about 50%. The contents of total phenols and total flavonoids were 24.71 mg GA eq./g DW and 7.36 mg Rutin eq./g DW, respectively.

Similar content being viewed by others

Abbreviations

- AA:

-

Ascorbic acid

- a:

-

Red values

- b:

-

Yellow value

- D0 :

-

Pre-exponential element in the Arrhenius equation (m2/s)

- Deff :

-

Effective diffusivity (m2/s)

- Ea :

-

Activation energy (kJ/mol)

- DW :

-

Dry weight

- DR :

-

Drying rate

- GAE:

-

Gallic acid equivalent

- RE:

-

Rutin equivalent

- L :

-

Lightness value

- L0 :

-

Half the thickness of the sample slice (m)

- M:

-

Moisture content (g water/g dry matter)

- M0 :

-

Initial moisture content (g water/g dry matter)

- Me :

-

Equilibrium moisture content (g water/g dry matter)

- MR:

-

Moisture ratio

- MRexp, i :

-

Respective actual measurements moisture content

- MRpre, i :

-

Theoretically calculated moisture content

- Mt + dt :

-

(G water/g dry matter)

- Mt :

-

(G water/g dry matter)

- N:

-

Number of assessments

- N:

-

Positive integer

- R2 :

-

Correlation coefficient

- RMSE:

-

Root mean square error

- R:

-

Universal gas constant (8.314 kJ/mol K)

- ST:

-

Slice thickness

- T:

-

Temperature (℃)

- Tabs :

-

Absolute temperature (K)

- t,:

-

Drying time (min)

- χ 2 :

-

Reduced chi-square

- z:

-

Number of drying constants

References

Shi QQ, Zhang Z, Su JJ, Zhou J, Li XG (2018) Comparative analysis of pigments, phenolics, and antioxidant activity of Chinese Jujube (Ziziphus jujuba Mill.) during fruit development. Molecules 23(8):1917

Rahman E, Momin A, Zhao L, Guo X, Xu D, Zhou F, Ji BP (2018) Bioactive, nutritional composition, heavy metal and pesticide residue of four chinese jujube cultivars. Food Sci Biotechnol 27:23–331

Lu Y, Bao, T, Mo, JL, Ni, JD, Chen W (2021) Research advances in bioactive components and health benefits of jujube (ziziphus jujuba mill.) fruit. J Zhejiang University-SCIENCE B 22(6):431–449

Wang CT, Cao JC, Jiang WB (2016) Effect of the drying method on browning of flesh, antioxidant compounds and antioxidant capacity of Chinese jujube (Zizyphus jujube mill.) fruit. Curr Top Nutraceut R 14(2):161–170

Doymaz İ, Karasu S, Baslar M (2016) Effects of infrared heating on drying kinetics, antioxidant activity, phenolic content, and color of jujube fruit. J Food Meas Charact 10(2):283–291

Osman İ, Aysel KF,Sabriye P (2015) Effects of open-air sun drying and pre-treatment on drying characteristics of purslane (portulaca oleracea L.). Heat Mass Transf 51(6):807–813

Doymaz İ, İsmail O (2012) Experimental characterization and modelling of drying of pear slices. Food Sci Biotechnol 21:1377–1381

Jha AK, Sit N (2020) Drying characteristics and kinetics of colour change and degradation of phytocomponents and antioxidant activity during convective drying of deseeded terminalia chebula fruit. J Food Meas Charact 14(4):2067–2077

An KJ, Wei L, Fu MQ, Cheng LN, Peng J, Wu JJ (2020) Effect of carbonic maceration (cm) on the vacuum microwave drying of Chinese ginger (zingiber officinale roscoe) slices: drying characteristic, moisture migration, antioxidant activity, and microstructure. Food Bioprocess Technol 13:1661–1674

Caliskan G, Dirim SN (2017) Drying characteristics of pumpkin (cucurbita moschata) slices in convective and freeze dryer. Heat Mass Transf 53(6):2129–2141

Azimi-Nejadian H, Hoseini SS (2019) Study the effect of microwave power and slices thickness on drying characteristics of potato. Heat Mass Transf 55(10):2921–2930

Hakan OM, Ahmet Ü, Mehmet MÖ, Ertekin C, Sonmete MH (2019) Erratum to: the effects of drying parameters on drying characteristics, colorimetric differences, antioxidant capacity and total phenols of sliced kiwifruit. Erwerbs-obstbau 61:195–207

Ning XF, Xu JT, Jang MK (2021) Drying characteristics and models of red ginseng slice using Far-Infrared rays. J Biosyst Eng 46:346–352

Lee JH, Zuo L (2013) Mathematical modeling on vacuum drying of Zizyphus jujube Miller slices. J Food Sci Technol 50(1):115–121

Fang SZ, Wang ZF, Hu XS (2009) Hot air drying of whole fruit Chinese jujube (Zizyphus jujuba Miller): thin-layer mathematical modeling. Int J Food Sci Tec 44(9):1818–1824

AOAC (2000) Official Methods of Analysis, 17th edn. The Association of Official Analytical Chemists, Gaithersburg, MD, US

Engin D, Yahya T (2017) The effect of pretreatments on air drying characteristics of persimmons. Heat Mass Transf 53:99–106

Darıcı S, Şen S (2015) Experimental investigation of convective drying kinetics of kiwi under different conditions. Heat Mass Transf 51(8):1167–1176

Demiray E, Tulek Y (2014) Drying characteristics of garlic (Allium sativum L) slices in a convective hot air dryer Heat Mass Transf 50:779–786

Zhang Y, Duan K, Song F, Chen WJ, Zhao SL (2016) Drying characteristics and heat requirement of coconut endocarp determined by simultaneous thermal analyzer. Heat Mass Transf 52:1891–1898

Nadi F, Tzempelikos D (2018) Vacuum drying of apples (cv. golden delicious): drying characteristics, thermodynamic properties, and mass transfer parameters. Heat Mass Transf 4:1–14

Sarpong F, Yu X, Zhou C, Oteng-Darko P, Amenorfe LP, Wu B, Bai J, Ma H (2018) Drying characteristic, enzyme inactivation and browning pigmentation kinetics of controlled humidity-convective drying of banana slices. Heat Mass Transf 54(10):1–14

Février H, Le Quéré J-M, Le Bail G, Guyot S (2017) Polyphenol profile, PPO activity and pH variation in relation to colour changes in a series of red-fleshed apple juices. LWT-Food Sci and Technol 85:353–362

Crank J (1979) The mathematics of diffusion. Oxford University Press

Lee JH, Kim HJ (2009) Vacuum drying kinetics of Asian white radish (Raphanus sativus L.) slices. LWT-Food Sci and Technol 42(1):180–186

Kumar N, Sarkar BC, Sharma HK (2011) Mathematical modelling of thin layer hot air drying of carrot pomace. J Food Sci Technol 49(1):33–41

Djendoubi Mrad N, Boudhrioua N, Kechaou N, Courtois F, Bonazzi C (2012) Influence of air drying temperature on kinetics, physicochemical properties, total phenolic content and ascorbic acid of pears. Food Bioprod Process 90(3):433–441

Rajkumar P, Kailappan R, Viswanathan R, Raghavan GSV (2007) Drying characteristics of foamed alphonso mango pulp in a continuous type foam mat dryer. J Food Eng 79(4):1452–1459

Wang ZF, Sun JH, Liao XJ, Chen F, Zhao GH, Wu JH, Hu XS (2007) Mathematical modeling on hot air drying of thin layer apple pomace. Food Res Int 40(1):39–46

Doymaz İ (2017) Drying kinetics, rehydration and colour characteristics of convective hot-air drying of carrot slices. Heat Mass Transf 53:25–35

Goyal RK, Kingsly ARP, Mnikaantan MR (2006) Ilyas S M. Thin-layer drying kinetics of raw mango slices. Biosyst Eng 95(1):43–49

Janjai S, Precoppe M, Lamlert N, Mahayothee B, Bala BK, Nagle M, Müller J (2011) Thin-layer drying of litchi (Litchi chinensis Sonn.). Food Bioprod Process 89(3):194–201

Aghbashlo M, kianmehr, M H, Samimi-Akhijahani H. (2008) Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energ Convers Manage 49(10):2865–2871

Sadin R, Chegini GR, Sadin H (2014) The effect of temperature and slice thickness on drying kinetics tomato in the infrared dryer. Heat Mass Transf 50(4):501–507

Liu Y, Wu J, Miao S, Chong C, Sun Y (2014) Effect of a modified atmosphere on drying and quality characteristics of carrots. Food Bioprocess Technol 7:2549–2559

Rizvi NP, Maroulis ZB, Marinos-Kouris D (1996) Moisture Diffusivity Data Compilation in Foodstuffs. Dry Technol 14(10):2225–2253

Gupta RK, Sharma A, Kumar P, Vishwakarma RK, Patil RT (2012) Effect of blanching on thin layer drying kinetics of aonla (Emblica officinalis) shreds. J Food Sci Technol 51(7):1294–1301

Doymaz İ (2011) Thin-layer drying characteristics of sweet potato slices and mathematical modeling. Heat Mass Transf 47(3):277–285

Vega-Gálvez A, Scala KD, Rodríguez K, Lemus-Mondaca R, Miranda M, López J, Perez-Won M (2014) Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L.var. Hungarian). Int J Food Eng 117:647–653

Acknowledgements

The authors appreciate the support from the Foundation for the Characteristic Discipline of Processing Technology of Plant Foods (No. YSTSXK201812).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, C., Tian, S. & An, X. The effects of drying parameters on drying characteristics, colorimetric differences, antioxidant components of sliced chinese jujube. Heat Mass Transfer 58, 1561–1571 (2022). https://doi.org/10.1007/s00231-022-03202-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03202-5