Abstract

Nowadays, challenges in gluten free breads (GFB) are focused on improving the nutritional and health benefits. Acorn flour is an underexploited sustainable ingredient, naturally gluten free, with many nutritional and technological advantages. The aim of this study was to explore the interaction of acorn flour supplementation (up to 35%) to rice flour and sourdough process to obtain rice based GFB. Different levels of rice flour replacement with acorn flour (0%, 23% and 35%), and sourdough (20%) were tested in a basic GFB recipe, and technological, nutritional, and functional GFB characteristics evaluated. The combination of acorn flour and sourdough was responsible for acidifying dough and bread. Breads containing 35:65 acorn flour: rice flour led to harder breads with lower crumb luminosity and with reddish and brownish tones, besides improved structural features when adding sourdough. That combination of sourdough and acorn flour reduced the rate and the extent of starch hydrolysis, as well as increase the minerals content, total phenolic compounds and antioxidant activity. Therefore, the combination of acorn flour and sourdough process allows obtaining rice based GFB with better nutritional pattern.

Similar content being viewed by others

Introduction

Gluten free (GF) products, particularly in the bakery sector, have been a growing trend in the last years, due to both consumption by celiac patients and other gluten-related disorders, and the preference of many consumers of avoiding gluten [1]. Despite all studies aiming to improve functional and technological characteristics, it is important to continuously pursue innovative solutions to obtain better GF formulations, since the ones present in the market do not completely meet GF consumers’ needs [2]. Special attention is being paid to improve nutritional aspects and increasing bioactive compounds, using different strategies focused on functional raw materials or processes [3].

Acorn flour is produced from acorns, the fruit of holm oak (Quercus ilex and Quercus rotundifolia), which is naturally gluten free. It is considered a sustainable underexploited ingredient, since it can be used for human nutrition, but for many decades it was not consumed [4]. It has been already tested in gluten free breads (GFB) made with flour/starch blends, such as corn and potato starch, rice and corn flour or buckwheat and rice flour containing potato starch [5,6,7,8]. In addition, owing the nutritional aspects, acorn flour is rich in: fiber, unsaturated fatty acids, vitamins, minerals and polyphenols [9, 10]. It is well known that polyphenols and antioxidant activity can have numerous health benefits [11], but process conditions can affect the bioavailability of these components [12]. In this context, the use of sourdough during fermentation has been described as an approach to increase the bioavailability and the concentration of bioactive compounds [13]. Nevertheless, in the particular case of GFB, sourdoughs have been commonly incorporated to improve nutritional and sensory profile, CO2 retention, shelf life, starch digestibility and glycemic index [2, 14,15,16,17]; apart from reducing the use of additives in bakery, following the market demand for clean labels and natural products [14, 15]. However, in a recent study about the effect of adding microalga (also a source of polyphenols) in gluten containing bread, the incorporation of sourdough resulted in an increase in the antioxidant activity (ABTS and DPPH), together with other positive effects [18]. In addition, Nissen et al. [19] reported an increase in the antioxidant activity in cricket flour bread, when added sourdough.

To the best of our knowledge, despite the promising results obtained with the individual application of acorn flour and sourdough in bread, acorn flour has been never applied in GFB formulations with sourdough. The aim of this work was to study the effect of the incorporation of acorn flour and sourdough to a control GFB formulation based on rice flour, to understand the impact of these two factors regarding nutritional, technological and functional bread characteristics, including in vitro starch hydrolysis.

Materials and methods

Ingredients & reagents

Rice flour (9.75% of protein (N × 5.95), 12.65% moisture) was purchased from Harinera La Meta (Lleida, Spain), acorn flour (moisture: 9.8 ± 0.1, protein: 4.8 ± 0.2, fat: 9.8 ± 0.9, ash: 1.6 ± 0, total fiber 10.5 ± 0.5 (from which insoluble 9.5 ± 0.2 and soluble 1.0 ± 0.3), and carbohydrates: 63.7 ± 1) from holm oak (Quercus rotundifolia), obtained from Terrius (Marvão, Portugal). Organic rye liquid sourdough and compressed baker’s yeast were provided by Lesaffre (Marcq-en-Baroeul, France). Commercial sourdough was selected for carrying out this study, as it was advisable by Rinaldi et al. [15], stressing the importance of using sourdough prepared under industrial similar conditions to allow its replication in GFB production industrial scale [15]. Hydroxypropylmethylcellulose (HPMC) (Methocel K4M) Food Grade were gifted by Dow (Michigan, USA) and the sunflower oil and salt acquired in the local market.

The reagents used were: phenol crystallized, maleic acid, and petroleum ether acquired from Scharlau (Scharlab, S.L. Barcelona, Spain). Standards for starch (93%), D-glucose and resistant starch (52.5%), together with GOPOD reagent were purchased from Megazyme (Megazyme, Dublin, Ireland). Folin–Ciocalteu’s reagent, acetic acid glacial extra pure (99.7%), ethanol, potassium persulfate, sodium hydroxide, methanol, hydrochloric acid, iron (III) chloride, sodium acetate, sodium carbonate, sulphuric acid (98%), and potassium hydroxide (98%) were acquired from Panreac (Panreac Química S.L.U., Barcelona, Spain). α-Amylase from porcine pancreas (type VI-B, ≥ 5 units/mg), 2,2-diphenyl-1-picrylhidrazyl radical (DPPH), 2,2-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) diammonium salt (ABTS), and calcium chloride dihydrate were obtained from Sigma-Aldrich (Sigma-Aldrich Produktions GmbH, Steinheim, Germany). 3,4,5-Trihydroxybenzoic acid (gallic acid), 6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid (Trolox), and 2,4,6-Tripyridyl-s-Triazine (TPTZ iron reagent), were purchased from Fluka (Fluka Chemika, Neu-Ulm, Switzerland). Finally, amyloglucosidase 1100 BG was acquired from Novozymes (Novozymes, Bagsvaerd, Denmark).

Flour blends proportion

Two different incorporation levels of acorn flour were tested: 23% and 35% in a control formulation of 100% rice flour. These ratios rice:acorn (77:23 and 65:35) were chosen due to the good results obtained in previous research [7], and also other authors findings, which reported better rheological and sensorial results in the bread, when acorn flour incorporation level was around 20% [5, 6].

Water binding capacity of flour blends

Water binding capacity (WBC) of the different flour blends was assessed following the method described by Espinosa-Ramirez et al. [20]. Blends were prepared according to the aforementioned proportions of rice:acorn, and WBC was expressed in g water/ g flour blends. Four replicates were performed for each blend.

Breadmaking

Rice based bread recipe, on flours basis, included: rice and acorn flours blend, 1.5% of salt, 2% of compressed yeast, and 2% of HPMC as a thickening agent. When sourdough was tested, breads were prepared with the same recipe but replacing 20% of the water amount with the liquid sourdough. According to the level of acorn flour (0, 23% and 35%), bread samples codes were A0-NSD, A23-NSD, A35-NSD, and their respective counterparts containing sourdough (SD) were denoted as A0-SD, A23-SD, A35-SD. The amount of water added was based on the WBC of the different flour blends.

Dried ingredients were mixed for 1 min using a Robot Coupe RM8 (Robot Coupe, Vincenne, France), followed by water addition, compressed yeast, and sourdough whenever required, and then mixed for 10 min. Next, 50 g of dough was placed into a silicone multi shape tray, fermented in a cabinet (Salva Industrial, Guipuzcoa, Spain) at 30 °C, and baked in a convection oven (Salva Industrial, Guipuzcoa, Spain) for 25 min at 180 °C. Last, breads were chilled for 1 h at room temperature. Two batches were prepared for each type of bread.

To optimize each formulation proofing time, the volume increase (ΔV) was recorded every 10 min up to 120 min. Optimum proofing time was established, considering the time needed to reach 75% of maximum dough volume, to allow additional expansion during oven rise. The procedure was done in duplicate.

pH and total titratable acidity (TTA) of dough and bread

Fermented doughs pH was measured with a potentiometer Crison PH25 + (Hach Lange Spain, S.L.U., Barcelona, Spain) at the end of proofing. Breads pH was determined mixing 1 g of bread with 9 mL of distilled water, and the pH was assessed with a Crison Basic pH 20. For Total Titratable Acidity (TTA), 1 g of dough or bread was suspended in 10 mL of distilled water and titrated with NaOH 1 N. TTA results were expressed in mL NaOH/10 g. The procedure was repeated three times, and mean value calculated.

Techno-functional properties of breads

Bake loss was calculated as the difference between the weight of dough before baking (50 g), and the final weight of bread after baking and cooling, divided by the initial weight of the dough.

After cooling, breads were carefully cut into 10 mm thickness slices, and color, morphology, and texture of crumbs evaluated. Bread color (crumb) was analyzed with a colorimeter Croma Meter CR-400 (Konica-Minolta Sensing Americas, New Jersey, USA), using the CIE L* a* b* system (International Commission on Illumination) with the parameters: L*—means lightness variability (L* = 0 black; L* = 100 white); a*—means from green ( – 60 < a* < 0) to red intensity (0 < a* < + 60); and b*—means from blue ( – 60 < b* < 0) to yellow intensity (0 < b* < + 60). Color differences (ΔE*) were measured with the equation: ΔE* = (ΔL*2 + Δa*2 + Δb*2)1/2, where ΔE* means the difference between the color of the breads, taking A0-NSD or A0-SD as the reference breads.

The morphology and crumb structure of bread slices were assessed using the procedure reported by Espinosa-Ramirez et al. [20], slightly adapted. Briefly, after scanning breads with a Scanner Perfection V600 photo (Epson, Suwa, Japan), at 600 dpi, images were analyzed using Fiji-ImageJ software [21], with the following settings: RGB channel, enhance contrast, and “otsu” algorithm. Parameters measured were: 2D slice area (cm2), mean cell area (mm2) and porosity (%). Slices from 3 different breads of each batch were analysed.

Bread texture measurements (hardness, adhesiveness, springiness, cohesiveness, chewiness, and resilience) were performed applying a double compression test (up to 50%) with a 36 mm aluminum probe, in a texturometer TA.XT2i (Stable Micro Systems, Surrey, UK). A round portion of crumb (20 mm ∅) cut from the center of the slice was used. At least 2 slices, from 4 different breads of each batch were analysed.

Chemical composition

Breads proximate composition was evaluated following standard methods of the International Organization for Standardization (ISO): moisture (712:2009), protein (16,634–2:2016), and total fat (11,085:2015). For ash content, AACC International Method [22] was used. Total starch was determined using Dubois et al. [23] methodology. Finally, total carbohydrates content was calculated by difference.

Total phenols content and antioxidant activity

Bread extracts were prepared as described in Beltrão-Martins et al. [8], with some modifications. First, 80 mg of freeze-dried bread were suspended in 1.5 mL extracting solvent (methanol/distilled water (70:30, v/v), and mixed with an ULTRA TURRAX T10 Basic (IKA®-Werke GmbH & Co. KG, Staufen, Germany) for 2 min. Samples were then centrifuged at 10000xg for 10 min at 4 °C and supernatant used for the colorimetric assays. Total phenols content (TPC) and antioxidant activity were analyzed through colorimetric methodologies, according to procedures previously performed and assessed, with minor modifications [24,25,26]. All analyses were performed using 96-well microplates (Thermo Fisher Scientific, Waltham, MA, USA), and a microplate reader Epoch (BioTek, Winooski, VT, U.S.A.), and were evaluated in triplicate (n = 3) for each sample. Bread’s total phenols content were quantified using the Folin–Ciocalteu reagent, with gallic acid as standard. Results were expressed in milligrams equivalent of gallic acid per gram of dry weight (mg GAE/ g DW) [25]. ABTS radical inhibition was determined through the expression: \({\text{\% inhibition}} = \left( {\frac{{{\text{Abs}}_{{{\text{blank}}}} - {\text{ Abs}}_{{{\text{sample}}}} }}{{{\text{Abs}}_{{{\text{blank}}}} }}} \right) \times 100.\) DPPH antioxidant activity and ferric reducing antioxidant power (FRAP), were calculated by Trolox calibration curve interpolation, and the results were expressed in mmol of Trolox per gram of dry weight (mmol Trolox/ g DW) [25,26,27].

In vitro starch hydrolysis

Starch hydrolysis was evaluated following the methodology described by Dura et al. [28]. Bread samples, containing 50 mg starch, were suspended into 4 mL of 0.1 M sodium maleate buffer (pH 6.9), containing porcine pancreatic α-amylase (0.9 U/mL), using a ULTRA TURRAX T18 Basic (IKA®-Werke GmbH & Co. KG, Staufen, Germany) at speed 3, and then incubated in a shaker incubator SKI 4 (ARGO Lab, Carpi, Italy) at 37 °C, under constant stirring at 200 rpm during 3 h. Aliquots (100 μL) were taken along the incubation, and 100 μl of cold ethanol 96% were added to stop the enzymatic activity. Next, samples (100 μL) were diluted with 885 µl of 0.1 M sodium acetate buffer (pH 4.5) and incubated with amyloglucosidase (214.5 U/mL) at 50 °C for 30 min in a shaking incubator. Glucose was quantified with the glucose oxidase–peroxidase (GOPOD) reagent kit, and the absorbance was read at 510 nm, in a microplate reader Epoch (BioTek, Winooski, VT, U.S.A.). For determining the resistant starch (RS), the unhydrolyzed starch after 16 h incubation was solubilized with cold 1.7 M NaOH. The mixture was homogenized with Polytron Ultra-Turrax T18 (IKA-Werke GmbH and Co. KG, Staufen, Germany) for 5 min at 14,000 rpm. Then, 8 mL 0.6 M sodium acetate (pH 3.8), containing calcium chloride (5 mM), were added, and the mixture was incubated with 100 μL AMG (143 U/mL) for 30 min at 50ºC, with continuous shaking. Glucose content was measured as described above. The absorbance was measured at 510 nm. Starch was calculated as glucose (mg) × 0.9. The parameters recorded were as reported [29]: rapidly digestible starch (RDS) corresponding to the starch hydrolyzed during the first 30 min; slowly digestible starch (SDS) or the starch hydrolyzed from 30 to 120 min of incubation time, and finally, RS the remnant starch after 16 h of incubation. According to Goñi et al. [30], in vitro starch hydrolysis kinetics, follows a nonlinear model that can be estimated by the equation: \({\varvec{C}}={{\varvec{C}}}_{\mathbf{\infty }}(1-{{\varvec{e}}}^{-{\varvec{k}}{\varvec{t}}})\), where C was the concentration at t time, \({{\varvec{C}}}_{\mathbf{\infty }}\) was the maximum hydrolysis extent, k was the kinetic constant, and t was the specific analyzed time [30].

Statistical analysis

Experimental data were statistically analysed using Statgraphics Centurion XVII (Statistical Graphics Corporation, UK). Analysis of variance (ANOVA) and principal component analysis (PCA) were performed. The results were presented as mean values with its respective standard deviation, and Fischer test with 95% of confidence level was used to analyze significancy between mean values (P < 0.05).

Results and discussion

Water binding capacity of flours blend and GF dough performance

To assess the water requirement, WBC of the blends (rice flour:acorn flour, 100:0, 77:23, 65:35) was determined. The WBC of each flour blend expressed as g water/g flours blend, was: 1.38, 1.32 and 1.29, respectively. Those levels of water were used for breadmaking.

The results obtained for dough proofing time, pH, TTA, and bake loss are recorded in Table 1. Proofing time was significantly reduced (P < 0.05) when introducing acorn flour in both bread’s recipes, with or without sourdough. The proofing was accelerated in the presence of acorn flour, which presents high sugar content, mainly sucrose and maltose (30% in dry basis), having also glucose (2%) and fructose (7%) [31]. The addition of sourdough only significantly reduced the fermentation time when the maximum acorn amount was tested (A35-SD). The presence of acorn also reduced (P < 0.05) the pH of the fermented dough, but without observing differences due to the level of acorn flour replacement, as reported by Beltrão-Martins et al. [7] using a different control formulation. As expected, a pH drop was observed in the presence of sourdough. Nevertheless, a slight rise of the pH was observed in A23-SD, comparing with A0-SD, but then A35-SD showed a decrease of pH, probably due to a buffering effect of acorn flour when present in smaller quantities. Breads showed higher pH than their corresponding doughs, but keeping the same trend regarding acorn and sourdough impact, previously mentioned for the doughs. Concerning TTA, as expected, fermented dough acidity increased significantly (P < 0.05) with the incorporation of sourdough and acorn flour, and the same behavior could be observed in bread TTA (P < 0.05), confirming the effect of both factors in dough and bread acidity. All type of breads had similar baking loss value, without any significant impact of acorn flour amount in the formulation.

Bread’s technologic characterization

The marketed sourdough was made from rye and wheat; but ELISA sandwich R5 test confirmed that the gluten content of the breads was 6 ppm, lower than the maximum value (20 ppm) established by Codex Alimentarius for gluten free foods. Figure 1 represents the cross section of each bread slice and the technologic parameters evaluated are gathered in Table 2. All parameters L*, a* and b* showed significant differences due to the addition of acorn flour (P < 0.05), whereas sourdough had only significant influence (P < 0.05) on L* and a*. With the addition of growing levels of acorn flour, L* value decreased gradually, signaling darker crumbs, that partially masked the significant effect of sourdough addition. Concerning a* and b* parameters, both increased with acorn level supplementation (P < 0.05), resulting in reddish and yellow color when compared to crumbs without acorn flour (A0-NDS or A0-SD) (Fig. 1, Table 2). Sourdough increased (P < 0.05) a*, keeping the contribution for reddish color, but b* did not show significant changes (p > 0.05). When comparing color difference (ΔE*) between breads without sourdough, the results obtained were: ΔE* (A0–A35) = 27.94, ΔE* (A0–A23) = 23.38, and ΔE* (A23–A35) = 4.58. For breads with sourdough, the results were: ΔE* (A0–A35) = 21.79, ΔE* (A0–A23) = 16.67, and ΔE* (A23–A35) = 5.18. Similar darker colors were reported when incorporating acorn flour in GFB [5, 6, 8], which might attract consumers, since darker breads are associated with higher quality, tradition, and healthier choices [32]. This is particularly important in GFB, because they usually have pale colors, being less appealing. Therefore, the addition of acorn flour naturally contributes to produce darker breads.

The slice 2D area, which is related to volume, increased significantly (P < 0.05), when using the maximum rice flour replacement with acorn flour (A35-NSD and A35-SD), which can also be seen in Fig. 1. It must be stressed that although other GFB containing acorn have been previously reported, only replacements up to 23% were reached without negatively affecting bread’s volume [5, 8]. In the present study, a very simple recipe was proposed, using blends of acorn flour with rice flour, compared to the complex matrixes that have been reported. Results confirmed that GFB were obtained using simplicity in the recipe design, but that was possible only after adapting the water hydration and optimizing the proofing time for each recipe.

Sourdough did not significantly (p > 0.05) modify the slice 2D area; however, other authors reported a reduction when adding sourdough to the formulation [33]. Apart from the adapted proofing time for each recipe, differences in the strains of LAB, as well as processing, yeast, ingredients composition, and also environment might be responsible of that difference [15, 32, 33].

Regarding crumb structure, sourdough presence resulted in more homogeneous crumbs (Fig. 1) with mean cells area significantly (P < 0.05) lower than that observed in their counterparts without sourdough (Table 2). Crumb’s porosity increased in breads with the highest percentage of acorn flour (A35-NSD and A35-SD). Korus et al. [5] observed the same trend, GFB porosity increased when enhancing acorn flour amount from 20 to 60%. Concerning sourdough, no significant (P > 0.05) effect was observed in porosity, although other studies have reported its increase [17, 32], but that could be ascribed to the recipes diversity.

Acorn levels and sourdough significantly affected texture parameters (Table 2), including hardness, adhesiveness, cohesiveness and chewiness, but springiness was only affected by the acorn levels, and neither factor modified crumb resilience. Sourdough presence increased the hardness of the breads (A0-NSD vs A0-SD). Hardness increased in acorn breads without sourdough, but this effect was counteracted in the presence of sourdough, since no differences were observed within the breads containing sourdough. Divergences have been reported about the impact of sourdough on bread texture inducing hardness increase [14, 15] or decrease [33], depending on the recipes. Usually, GFB are very adhesive due to high moisture content and high starchy composition, but acorn addition reduced the adhesiveness, although also the cohesiveness, independently of the level of incorporation. Breads with acorn flour had higher springiness, showing better recovery capacity after compression. Texture parameters of A35-SD were alike to those reported for GFB containing sourdough (30%) and chestnut flour (45%), that showed significant higher hardness (4.47 N ± 0.73), lower cohesiveness (0.78 N ± 0.73), higher chewiness (3.36 ± 0.55), and negligible resilience values [15].

Nutritional composition of breads

The inclusion of acorn resulted in a significant increase in fat and minerals with a simultaneous reduction in proteins and starch due to rice flour dilution with acorn flour (Table 3). Protein and fat content of acorn and rice flour were 4.76% and 9.75%, and 10.96% and 0.96%, respectively. The addition of sourdough provided an additional increase in protein content. Regarding fat content, it is important to highlight that acorn flour contains unsaturated fats, mainly oleic acid (60%) and linoleic acid (16%) [8, 23]. Therefore, the combination of acorn flour with sourdough in GFB, allows keeping proteins content, plus the nutritional advantages that acorn flour provides. Thus, increasing total fat, particularly unsaturated fatty acids, and minerals.

Total phenol content and antioxidant activity

Many studies revealed that acorn is rich in polyphenols, and consequently its flour can be an important source of phenolic compounds in bakery products [9, 34,35,36]. As expected, TPC increased significantly (P < 0.05) when increasing the level of acorn flour (Table 3), and that effect was even enhanced in the presence of sourdough. Although when comparing breads without acorn (A0-NSD and A0-SD) no significant effect was ascribed to sourdoughs. This result agrees with previous findings adding acorn flour to the formulation of biscuits and bread [6, 8, 34, 35]. Several studies reported the increase of TPC when sourdough was added to GFB [16, 18, 19, 39]. In general, it is agreed that sourdough fermentation facilitates the extractability of phenolic compounds, both from the ingredients and from the LAB metabolism, increasing its concentration. Nevertheless, since no effect was observed in control breads, the most plausible explanation might be that acorn flour could act as substrate for LAB, allowing them to produce more metabolites, and consequently increasing phenolic compounds release [16, 38].

Acorn flour significantly (P < 0.05) increase the antioxidant activity, independently of the use of sourdough. Regarding the effect of sourdough in bread’s antioxidant activity, previous studies reported an increase when added to bread [18, 19, 37]. Olojede et al. [39] did not find any effect in the antioxidant activity in GFB measured using the DPPH assay, which agrees with present study. Likely, the TPC coming from sourdough, would not be acting as antioxidants or their antioxidant activity could be lost during breadmaking stages. In fact, fermentation can affect the antioxidant activity of phenolic compounds in final products, either increasing or decreasing it, due to the association with other compounds that influence antioxidant activity [40]. It is also important to consider LAB strains differences among sourdoughs, and their diverse metabolism depending on the matrix composition [16, 40].

In vitro starch hydrolysis

The impact of acorn and sourdough on in vitro starch hydrolysis and the different starch fractions was evaluated (Table 3). Increasing levels of acorn flour in GFB resulted in a significant (P < 0.05) drop in RDS, but only at the highest level of acorn flour tested (A35-NSD). The same effect was obtained in the presence of sourdough, which masked the individual effect or acorn flour. Therefore, a reduction of RDS could be reached using sourdough, independently on the raw material. Acorn flour also reduced the amount of SDS, but again, only at the highest level tested. However, sourdough have not shown impact (p > 0.05) in this starch fraction. RS significantly (P < 0.05) increased with the introduction of acorn flour. Usually GF breads have high RDS and lower RS, which leads to high glycemic index [42], thus acorn flour could be a strategy to improve their performance on starch hydrolysis.

In Fig. 2, at first glance was visible the reduction in the starch hydrolysis that was induced by the sourdough, slowing down the rate (k) and the extent (C∞) of starch hydrolysis (Table 3). The major impact of acorn flour was on the extent of starch hydrolysis that was significantly (P < 0.05) reduced in breads containing 35% acorn flour in the blends. Sciarini et al. [41] and Fratelli et al. [42], concluded that increasing bread’s fiber and resistant starch content, led to a reduction of starch hydrolysis, and consequently of glycaemic index. Acorn flour presents around 10% fibre, which also could have contributed to lowering starch hydrolysis level. GFB usually presents high levels of starch hydrolysis and consequently higher glycemic index [42]. Thus, acorn flour and sourdough played an important role in this process, since results were in line of lowering starch hydrolysis, that might be related to acorn fiber, LAB metabolism [13, 16], or polyphenols from acorn flour, since polyphenols enrichment has been a strategy to reduce starch hydrolysis [37, 40, 43].

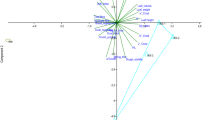

Principal component analysis (PCA)

To get a better picture of acorn flour impact on rice based GFB and the sourdough breadmaking process, a principal component analysis (PCA) was performed (Fig. 3). Two components could explain 86.88% of the variability among samples, 56.47% of that variability was explained with Component 1 (presence of acorn and level of incorporation) and 30.41% of the variability with Component 2, associated to the absence or presence of sourdough. When analyzing the plot, results shown that breads were clearly clustered by the level of acorn incorporation (PC1) along x-axis, and the presence or absence of sourdough (PC2) along y-axis. Positive area of PC1 was discriminated by high pH, adhesiveness, and protein content, and also faster and extended starch hydrolysis, that was mainly represented by the samples A0-NSD and A0-SD. Negative area of PC1 grouped mainly A35-SD and A35-NSD breads that have high TTA in dough and bread, and high hardness, minerals and fat content, apart from the TPC and antioxidant activities. Sourdough containing breads were on the positive y-axis, providing acidity to doughs and breads, increasing hardness of the breads crumbs that showed more porosity, and contributing to the amount of proteins and minerals. In general, sourdough minimizes the influence of acorn flour, since breads without sourdough were equidistantly distributed along x-axis, which did not happen with breads A23-SD and A35-SD, with sourdough.

Conclusions

The combination of acorn flour with sourdough in rice-based GFB, have shown promising results in technological, nutritional, and functional characteristics. The nutritional benefits provided by acorn flour, such as unsaturated fatty acids, and those associated to their polyphenol content, could be incorporated into rice-based breads, containing 35:65 acorn flour:rice flour. Resulting breads had dark crumb, whose structure was improved with the addition of sourdough. Moreover, acorn flour reduced the rate and extent of starch hydrolysis. Overall, the combination of acorn flour and sourdough revealed being a positive strategy to improve GFB quality, allowing making GFB with high content of acorn flour. Nevertheless, sourdough contribution to antioxidant activity in GFB, would need further investigation, to better understand possible interactions among constituents and process.

References

Xhakollari V, Canavari M, Osman M (2019) Factors affecting consumers’ adherence to gluten-free diet, a systematic review. Trends Food Sci Technol 85:23–33. https://doi.org/10.1016/j.tifs.2018.12.005

Cappelli A, Oliva N, Cini E (2020) A systematic review of gluten-free dough and bread: Dough rheology, bread characteristics, and improvement strategies. Appl Sci. https://doi.org/10.3390/APP10186559

Capriles VD, dos Santos FG, Arêas JAG (2016) Gluten-free breadmaking: Improving nutritional and bioactive compounds. J Cereal Sci. https://doi.org/10.1016/j.jcs.2015.08.005

Vinha AF, Barreira JCM, Costa ASG, Oliveira MBPP (2016) A New age for quercus spp fruits: review on nutritional and phytochemical composition and related biological activities of acorns. Compr Rev Food Sci Food Saf 15:947–981. https://doi.org/10.1111/1541-4337.12220

Korus J, Witczak M, Ziobro R, Juszczak L (2015) The influence of acorn flour on rheological properties of gluten-free dough and physical characteristics of the bread. Eur Food Res Technol. https://doi.org/10.1007/s00217-015-2417-y

Skendi A, Mouselemidou P, Papageorgiou M, Papastergiadis E (2018) Effect of acorn meal-water combinations on technological properties and fine structure of gluten-free bread. Food Chem. https://doi.org/10.1016/j.foodchem.2018.01.144

Martins RB, Nunes MC, Ferreira LMM, Peres JA, Barros AIRNA, Raymundo A (2020) Impact of acorn flour on gluten-free dough rheology properties. Foods. https://doi.org/10.3390/foods9050560

Beltrão Martins R, Gouvinhas I, Nunes MC, Alcides Peres J, Raymundo A, Barros AIRNA (2020) Acorn flour as a source of bioactive compounds in gluten-free bread. Molecules 25(16):3568

Silva S, Costa EM, Borges A, Carvalho AP, Monteiro MJ, Pintado MME (2016) Nutritional characterization of acorn flour (a traditional component of the Mediterranean gastronomical folklore). J Food Meas Charact 10:584–588. https://doi.org/10.1007/s11694-016-9340-1

Vinha AF, Costa ASG, Barreira JCM, Pacheco R, Oliveira MBPP (2016) Chemical and antioxidant profiles of acorn tissues from Quercus spp.: Potential as new industrial raw materials. Ind Crops Prod. https://doi.org/10.1016/j.indcrop.2016.08.027

Ruskovska T, Maksimova V, Milenkovic D (2020) Polyphenols in human nutrition: from the in vitro antioxidant capacity to the beneficial effects on cardiometabolic health and related inter-individual variability – an overview and perspective. Br J Nutr 123:241–254. https://doi.org/10.1017/S0007114519002733

Ribas-Agustí A, Martín-Belloso O, Soliva-Fortuny R, Elez-Martínez P (2018) Food processing strategies to enhance phenolic compounds bioaccessibility and bioavailability in plant-based foods. Crit Rev Food Sci Nutr 58:2531–2548. https://doi.org/10.1080/10408398.2017.1331200

Gobbetti M, Rizzello CG, Di Cagno R, De Angelis M (2014) How the sourdough may affect the functional features of leavened baked goods. Food Microbiol 37:30–40. https://doi.org/10.1016/j.fm.2013.04.012

Moroni AV, Dal Bello F, Arendt EK (2009) Sourdough in gluten-free bread-making: An ancient technology to solve a novel issue? Food Microbiol. https://doi.org/10.1016/j.fm.2009.07.001

Rinaldi M, Paciulli M, Caligiani A, Scazzina F, Chiavaro E (2017) Sourdough fermentation and chestnut flour in gluten-free bread: A shelf-life evaluation. Food Chem. https://doi.org/10.1016/j.foodchem.2016.12.055

Gobbetti M, De Angelis M, Di Cagno R, Calasso M, Archetti G, Rizzello CG (2019) Novel insights on the functional/nutritional features of the sourdough fermentation. Int J Food Microbiol 302:103–113. https://doi.org/10.1016/j.ijfoodmicro.2018.05.018

Menezes LAA, Molognoni L, de SáPloêncio LA, Costa FBM, Daguer H, Deaindner J (2019) De Use of sourdough fermentation to reducing FODMAPs in breads. Eur Food Res Technol 245:1183–1195. https://doi.org/10.1007/s00217-019-03239-7

Garzon R, Skendi A, Lazo-Vélez M, Papageorgiou M, Rosell C (2020) Interaction of dough acidity and microalga level on bread quality and antioxidant properties. Food Chem. https://doi.org/10.1016/j.foodchem.2020.128710

Nissen L, Samaei SP, Babini E, Gianotti A (2020) Gluten free sourdough bread enriched with cricket flour for protein fortification: Antioxidant improvement and Volatilome characterization. Food Chem 333:127410. https://doi.org/10.1016/j.foodchem.2020.127410

Espinosa-Ramírez J, Garzon R, Serna-Saldivar SO, Rosell CM (2018) Mimicking gluten functionality with β-conglycinin concentrate: Evaluation in gluten free yeast-leavened breads. Food Res Int 106:64–70. https://doi.org/10.1016/j.foodres.2017.12.055

Schindelin J, Arganda-Carreras I, Frise E, Kaynig V, Longair M, Pietzsch T, Preibisch S, Rueden C, Saalfeld S, Schmid B et al (2012) Fiji: an open-source platform for biological-image analysis. Nat Methods 9:676–682. https://doi.org/10.1038/nmeth.2019

AACC International Method 08–01.01 1999 AACC International Method 08–01.01 Ash—Basic Method Final approval April 13, 1961; Reapproval November 3, 1999

Dubois M, Gilles K, Hamilton JK, Rebers PA, Smith F (1951) A colorimetric method for the determination of sugars. Nature 168:167. https://doi.org/10.1038/168167a0

AOAC Official Methods of Analysis of AOAC INTERNATIONAL, 20th ed; AOAC International: Arlington, VA, USA, 2016

Gouvinhas I, Santos RA, Queiroz M, Leal C, Saavedra MJ, Domínguez-Perles R, Rodrigues M, Barros AIRN (2018) Monitoring the antioxidant and antimicrobial power of grape (Vitis vinifera L) stems phenolics over long-term storage. Ind Crops Prod 126:83–91. https://doi.org/10.1016/j.indcrop.2018.10.006

Machado NFL, Domínguez-Perles R (2017) Addressing facts and gaps in the phenolics chemistry of Winery by-products. Molecules 22:286. https://doi.org/10.3390/molecules22020286

Teixeira-Guedes CI, Oppolzer D, Barros AI, Pereira-Wilson C (2019) Impact of cooking method on phenolic composition and antioxidant potential of four varieties of Phaseolus vulgaris L. and Glycine max L. LWT 103:238–246. https://doi.org/10.1016/j.lwt.2019.01.010

Dura A, Błaszczak W, Rosell CM (2014) Functionality of porous starch obtained by amylase or amyloglucosidase treatments. Carbohydr Polym 101:837–845. https://doi.org/10.1016/j.carbpol.2013.10.013

Englyst HN, Hudson GJ (1996) The classification and measurement of dietary carbohydrates. Food Chem 57:15–21. https://doi.org/10.1016/0308-8146(96)00056-8

Goñi I, Garcia-Alonso A, Saura-Calixto F (1997) A starch hydrolysis procedure to estimate glycemic index. Nutr Res 17:427–437. https://doi.org/10.1016/S0271-5317(97)00010-9

Correia PR, Leitão AE, Beirão-Da-Costa ML (2009) Effect of drying temperatures on chemical and morphological properties of acorn flours. Int J Food Sci Technol 44:1729–1736. https://doi.org/10.1111/j.1365-2621.2009.01988.x

De Boni A, Pasqualone A, Roma R, Acciani C (2019) Traditions, health and environment as bread purchase drivers: A choice experiment on high-quality artisanal Italian bread. J Clean Prod 221:249–260. https://doi.org/10.1016/j.jclepro.2019.02.261

Jagelaviciute J, Cizeikiene D (2021) The influence of non-traditional sourdough made with quinoa, hemp and chia flour on the characteristics of gluten-free maize/rice bread. Lwt 137:110457. https://doi.org/10.1016/j.lwt.2020.110457

Atzler SWHJJ, Zannini MHE (2019) Impact of different S cerevisiae yeast strains on gluten-free dough and bread quality parameters. Eur Food Res Technol 245:213–223. https://doi.org/10.1007/s00217-018-3154-9

Parsaei M, Goli M, Abbasi H (2018) Oak flour as a replacement of wheat and corn flour to improve biscuit antioxidant activity. Food Sci Nutr. https://doi.org/10.1002/fsn3.524

Pasqualone A, Makhlouf FZ, Barkat M, Difonzo G, Summo C, Squeo G, Caponio F (2019) Effect of acorn flour on the physico-chemical and sensory properties of biscuits. Heliyon 5:e02242. https://doi.org/10.1016/j.heliyon.2019.e02242

Szabłowska E, Tańska M (2021) Acorn flour properties depending on the production method and laboratory baking test results: A review. Compr Rev Food Sci Food Saf 20:980–1008. https://doi.org/10.1111/1541-4337.12683

O’Shea N, Arendt E, Gallagher E (2014) State of the art in gluten-free research. J Food Sci. https://doi.org/10.1111/1750-3841.12479

Olojede AO, Sanni AI, Banwo K, Adesulu-Dahunsi AT (2020) Sensory and antioxidant properties and in-vitro digestibility of gluten-free sourdough made with selected starter cultures. Lwt 129:109576. https://doi.org/10.1016/j.lwt.2020.109576

Adebooye OC, Alashi AM, Aluko RE (2018) A brief review on emerging trends in global polyphenol research. J Food Biochem 42(4):e12519

Sciarini LS, Bustos MC, Vignola MB, Paesani C, Salinas CN, Pérez GT (2017) A study on fibre addition to gluten free bread: its effects on bread quality and in vitro digestibility. J Food Sci Technol 54:244–252. https://doi.org/10.1007/s13197-016-2456-9

Fratelli C, Muniz DG, Santos FG, Capriles VD (2018) Modelling the effects of psyllium and water in gluten-free bread: An approach to improve the bread quality and glycemic response. J Funct Foods 42:339–345. https://doi.org/10.1016/j.jff.2018.01.015

Kan L, Oliviero T, Verkerk R, Fogliano V, Capuano E (2020) Interaction of bread and berry polyphenols affects starch digestibility and polyphenols bio-accessibility. J Funct Foods 68:103924. https://doi.org/10.1016/j.jff.2020.103924

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. Authors acknowledge the financial support of Grant RTI2018-095919-B-C21 funded by MCIN/AEI/1013039/501100011033, “ERDF A way of making Europe”, FCT-Portuguese Foundation for Science and Technology (PD/BD/135332/2017) under the Doctoral Program “Agricultural Production Chains – from fork to farm” (PD/00122/2012) and from the European Social Funds and the Regional Operational Program Norte 2020. This study was also supported by research units: CITAB (UIDB/04033/2020), Centro de Química de Vila Real (UIDB/00616/2020) and LEAF UIDB/04129/2020.

Author information

Authors and Affiliations

Contributions

CRediT authors statement: RBM: investigation and methodology, data curation and formal analysis, roles/writing—original draft RG: methodology, supervision, data curation and formal analysis, writing—review and editing José Alcides Peres: funding acquisition, writing—review and editing AIRNAB: funding acquisition, writing—review and editing AR: funding acquisition, writing—review and editing CMR: conceptualization, methodology, supervision, writing—review and editing, and funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have declared no conflict of interest that are relevant to the content of this article.

Compliance with Ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Beltrão Martins, R., Garzón, R., Peres, J.A. et al. Acorn flour and sourdough: an innovative combination to improve gluten free bread characteristics. Eur Food Res Technol 248, 1691–1702 (2022). https://doi.org/10.1007/s00217-022-03996-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-03996-y