Abstract

The worldwide availability of lignocellulosic wastes represents a serious environmental challenge with potential opportunities. Xylanases are crucial in lignocellulosic bio-hydrolysis, but the low enzyme productivity and stability are still challenges. In the current study, Bacillus subtilis (coded ARSE2) revealed potent xylanase activity among other local isolates. The enzyme production optimization revealed that maximum enzyme production (490.58 U/mL) was achieved with 1% xylan, 1.4% peptone, and 5% NaCl at 30 °C and pH 9. Furthermore, several lignocellulosic wastes were exploited for sustainable xylanase production, where sugarcane bagasse (16%) under solid-state fermentation and woody sawdust (2%) under submerged fermentation supported the maximum enzyme titer of about 472.03 and 485.7 U/mL, respectively. The partially purified enzyme revealed two protein bands at 42 and 30 kDa. The partially purified enzyme revealed remarkable enzyme activity and stability at 50–60 °C and pH 8–9. The enzyme also revealed significant stability toward tween-80, urea, DTT, and EDTA with Vmax and Km values of 1481.5 U/mL and 0.187 mM, respectively. Additionally, the purified xylanase was applied for xylooligosaccharides production, which revealed significant antimicrobial activity toward Staphylococcus aureus with lower activity against Escherichia coli. Hence, the locally isolated Bacillus subtilis ARSE2 could fulfill the xylanase production requirements in terms of economic production at a high titer with promising enzyme characteristics. Additionally, the resultant xylooligosaccharides revealed a promising antimicrobial potential, which paves the way for other medical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The continuous accumulation of lignocellulosic wastes represents a great growing environmental challenge. Cellulose and hemicellulose are the major constituents of agricultural wastes that could be suitable candidates for sustainable biorefinery industries (Devi et al. 2022). Several attempts were directed at the valorization of such substrates; however, high cost invested and low selectivity remain challenging (Malhotra and Chapadgaonkar 2018; Trejo et al. 2022). From the environmental perspective, the application of enzymes for lignocellulose hydrolysis gained much attention as an eco-friendly and cost-effective alternative for biomass conversion (Sunkar et al. 2020). Xylan represents 20–30% of hemicellulose, and hence, xylanases were widely reported as a promising tool for efficient agricultural wastes valorization to value-added products (Sunkar et al. 2020; Ontañon et al. 2021). Xylanases catalyze the hydrolyze β-1,4 glycosidic linkages in xylan to release β-d-xylopyranosyl mono-, di-, and trisaccharides (Malhotra and Chapadgaonkar 2018). The resulting saccharides are amenable to microbial fermentation which opens the scope for diverse promising applications (Ghosh et al. 2021; Vasić et al. 2021). Currently, xylanases are ranked among the most demanded enzymes with a large market share attributed to their numerous industrial applications (Van Hoeck et al. 2021; Golgeri et al. 2022).

Xylanases have recently acquired industry interest in biofuel production, pharmaceutical sectors, specific chemical manufacturing, wood pulp bioleaching for papermaking, food/beverage manufacturing, and animal nutrition (Basit et al. 2020; Qeshmi et al. 2020; Ghosh et al. 2021; Miao et al. 2021). The growing demand for xylanases forced their large-scale production at a cost-effective and commercial-scale level (Ramanjaneyulu and Rajasekhar Reddy 2016). Among others, microbial xylanases fulfill the biotechnological requirements for large-scale production in terms of scalability and production titer (Basit et al. 2020). Different microbial sources were reported for xylanase production including yeasts (Miao et al. 2021; Šuchová et al. 2022), fungi (Cekmecelioglu and Demirci 2020; Patel and Dudhagara 2020a), and actinomycetes (Danso et al. 2022). Currently, eubacteria are largely applied at commercial-scale xylanases’ production (Chakdar et al. 2016; Ghosh et al. 2021). Several bacterial genera are reported for xylanases production, including Cellulomonas, Paenibacillus, and Micrococcus with dominant superiority of Bacillus species in terms of production efficiency and enzyme characteristics (Mmango-Kaseke et al. 2016; Patel and Dudhagara 2020b; Ghosh et al. 2021; Ontañon et al. 2021). Regarding the high production cost using pure xylan, sustainable xylanase production is currently directed toward the utilization of agricultural wastes along with the development of efficient production strategies (Biswas et al. 2010). Hence, several agricultural wastes and food industries were implied in the economic xylanase production process such as wheat straw, rice straw, and sugarcane bagasse. This direction not only reduce the production cost, but also reduce the environmental impacts of such wastes.

Furthermore, the xylooligosaccharides (XOS) attract great intention regarding their promising biological activities including anticancer, anti-inflammatory, and antioxidant characteristics (Gowdhaman et al. 2014; Ghosh et al. 2021). Regarding the widespread of multidrug-resistant microbial pathogen, a few studies reported the antimicrobial potentials of XOS against some human pathogens. Therefore, it was of interest to explore xylanases production using local bacterial isolate and optimize the enzyme production process on low-cost agricultural and industrial residues. Furthermore, the enzyme characteristics and kinetics was evaluated for purified enzyme. Additionally, the XOS resulted from xylan hydrolysis with purified enzyme were evaluated for potential antimicrobial activity against some multidrug-resistant pathogens.

Materials and methods

Bacterial isolation and purification

For the isolation of xylan-degrading bacteria, six samples were collected from three different sources (Assiut, Egypt), including garden soil (27°12′16.42″N, 31°10′48.06″E), decayed agricultural wastes (27°11′39.71″N, 31°31′45.53″E), and ruminant dung (27°12′16.06″N, 31°6′51.46″E). All samples (10 g/sample) were serially diluted (10–1–10–6) in sterile saline solution (0.9% NaCl) under shaking for 1 h. Under aseptic conditions, 100 µL from the serially diluted samples was separately spread into xylan agar (XA) medium containing (g/L): xylan, 5.0; peptone, 5.0; yeast extract, 5.0; K2HPO4, 1.0; MgSO4.7H2O, 0.2; and agar 15, at pH 7.0. All plates were incubated at 37 °C for 72 h. The growing separate colonies were picked out and streaked again on XA plates to ensure purity.

Screening of xylanase activity on XA plates

All purified bacterial isolates were separately streaked on the XA plates and incubated at 37 °C for 72 h. The xylanolytic activity was assessed by flooding the plates for 15 min with 0.1% (w/v) Congo red (Sigma-Aldrich, USA). Afterward, the stain was discarded, and the excess stain was removed with 1 M NaCl for 10 min. The developing clear zones (Halo-zones) around bacterial colonies indicate xylanase activity (Samanta et al. 2011).

Quantitative determination of xylanase activity

The xylanase activity was further evaluated quantitatively through the dinitrosalicylic acid method (DNS) using birchwood xylan (Sigma-Aldrich, USA) as a substrate (Bailey et al. 1992). First, all bacterial isolates with xylanase activity were inoculated separately (5% inoculum, 1.0 × 105 CFU/mL) into 100 mL of xylanase broth medium (XB) and incubated under shaking (200 rpm) at 37 °C for 72 h. Afterward, the cell-free supernatants (CFS) were used as a source for crude enzymes. The CFS (0.2 mL) was added to 1.8 mL of birchwood xylan (1.0% prepared in 0.05 M sodium citrate buffer, pH 5.3) and incubated at 50 °C for 10 min. The reaction was stopped by 3.0 mL of DNS solution and then boiled at 100 °C for 15 min. After cooling, the developed color was measured at 540 nm. The enzyme activity (one unit) is defined as the amount of enzyme required to release 1 μmol of xylose/min under the defined assay conditions.

Identification of the potent xylanase-producing isolate

The most potent xylanase-producing isolate was identified according to morphological and biochemical characteristics. Furthermore, sugar fermentation and substrate assimilation, including starch, gelatin, carboxymethyl cellulose (CMC), etc., were also evaluated.

At the molecular level, the isolate was identified according to the 16S rRNA sequencing approach. The total genomic DNA was extracted using a DNA isolation kit (Axygen, Biosciences Co., USA). Later, two universal primers were used to amplify the 16S rRNA gene: 27F (5′-GAGAGTTTGATCCTGGCTCAG-3′) and 1492R (5′-TACCTTGTTACGACTT-3′) through polymerase chain reaction (PCR). The PCR product was purified through QI quick DNA purification kit (Qiagen, USA) according to the manufacturer’s instructions and sequenced by a 3130X-automated DNA sequencer (Applied Biosystems, USA). The 16S rRNA gene sequence of strain ARSE2 was compared with the reference sequences published on the National Center for Biotechnology Information GenBank (NCBI GenBank) database using the Basic Local Alignment Search Tool (BLAST). Moreover, the sequence alignment was carried out by ClastalW, and the phylogenetic tree was constructed and analyzed using MEGA 6 software.

Optimization of xylanase production conditions

Various nutritional factors and cultivation conditions were evaluated through a one-variable-at-a time approach to maximize the xylanase production through ARSE2 isolate. Generally, the XB was used as a basal production medium and xylanase activity was measured after 48 h of incubation at 37 °C, under shaking conditions of 200 rpm (except for temperature and incubation time effects). Additionally, the bacterial growth was also determined at 600 nm (OD600).

Effect of different carbon sources on xylanase production

To determine the best carbon source for xylanase production, various simple and complex carbon sources, including glucose, lactose, fructose, sucrose, starch, CMC, mannose, xylose, ribose, galactose, and birchwood xylan, were used separately as the sole source of carbon (1% w/v).

Effect of different nitrogen sources on xylanase production

Various organic and inorganic nitrogen sources were screened for their ability to support maximal xylanase production. The organic nitrogen sources included gelatin, tryptone, peptone, yeast extract, and beef extract, while the inorganic nitrogen sources were ammonium sulfate (NH4)2SO4, ammonium nitrate (NH4NO3), sodium nitrate (NaNO3), ammonium dihydrogen phosphate (NH4H2PO4), and urea. Each nitrogen source was used at a final concentration of 0.5% (w/v) in the XB medium. Furthermore, the optimum level of the nitrogen source supporting the highest xylanase activity (optimum nitrogen source) was investigated at different concentrations in the range of 0.2–8% (w/v).

Effect of sodium chloride (NaCl) concentrations on xylanase production

The effect of NaCl on xylanase production was evaluated by supplementing the XB medium with different concentrations of NaCl from 1 to 7% (w/v).

Effect of different metals and amino acids on xylanase production

Different metals, including potassium chloride (KCl), calcium chloride (CaCl2), nickel chloride (NiCl2), barium chloride (BaCl2), cobalt chloride (CoCl2), magnesium chloride (MgCl2), and copper chloride (CuCl2), were investigated for xylanase production, at 0.05% final concentrations. Additionally, seven different amino acids were investigated for their effects on xylanase production, including lysine, glycine, cysteine, serine, methionine, tryptophan, and glutamic acid. Controls without any supplemented metals or amino acids were included.

Effect of cultivation temperature and medium pH on xylanase production

To determine the optimum temperature for xylanase production, the potent xylanase-producing isolate was cultivated at different incubation temperatures (20–60 °C) on the XB medium. On the other hand, to determine the optimum pH for xylanase production, the isolate was grown on XB at 37 °C with different initial pH values of 3.0–11.0. The enzyme activity was determined after 48 h of incubation at each specified temperature or pH value.

Effect of inoculum size and incubation period on xylanase production

Different inoculum sizes [1, 2, 3, 4, 5, 6, 8, 10, and 14% (v/v)] from the potent xylanase producers were inoculated in 250 mL Erlenmeyer flasks containing 100 mL of the sterilized XB medium. To prepare the inoculation pre-culture, the potent xylanase producer (ARSE2) was grown on nutrient broth for 18 h at 37 °C.

On the other hand, the optimum incubation period for maximum xylanase production was evaluated by following the enzyme production for 108 h on the XB medium and incubated at 37 °C under shaking (200 rpm). Samples were withdrawn under aseptic conditions every 12 h and assayed for both enzyme activity and bacterial growth (OD600).

Lignocellulosic waste types and pre-treatment

Xylanase production was evaluated using different agricultural and industrial wastes, including wheat straw, rice straw, sugarcane bagasse, corn stalks, woody sawdust, cotton stalks, and bean straw. The wastes were first air-dried and ground into a fine powder. Afterward, the powders were separately treated with NaOH solution (1%) in a final solid:liquid ratio of 1:10 for 2 h at room temperature. The treated powder was filtered to remove the excess base, washed several times with distilled water, and autoclaved (final substrate: distilled water ratio of 1:10) for 1 h. After that, the treated substrates were filtered and washed with distilled water until the wash water became neutral and then air-dried.

Application of treated lignocellulosic wastes for xylanase production under solid-state (SSF) and submerged fermentation (SF)

The effect of treated agro-industrial wastes on xylanase production was evaluated under SSF and SF conditions. In SSF, 16 g of each pre-treated substrate was added to a 250 mL Erlenmeyer flask containing 100 mL of the following mineral salt solution (g/L): MgSO4.7H2O, 0.3; K2HPO4, 2.0 at pH 7.0. After autoclaving for 15 min, all flasks were inoculated with an overnight culture of ARSE2 isolate and incubated at 37 °C for 72 h under static conditions. Afterward, xylanase enzymes were extracted with 100 mL of 50 mM sodium citrate buffer (pH 5.3) and filtered. The CFS was used as a source for xylanase activity. On the other hand, to study the effect of SF upon xylanase production, 2% of each waste was added separately to 250 mL Erlenmeyer flasks containing 100 mL of the previous mineral salt solution and incubated at 37 °C for 72 h under shaking (200 rpm).

Partial purification of the produced xylanase

For enzyme purification, the most potent isolate (ARSE2) was incubated under optimum xylanase production conditions, and the CFS was used as a crude enzyme source. The protein contents of CFS were salted out by gradually adding ammonium sulfate up to 75% (w/v) saturation under mild stirring at 4 °C. After 24 h of stirring at 4 °C, the solution was centrifuged at 10,000 rpm for 15 min. The resulting protein pellet was then collected, dissolved in a minimum amount of phosphate buffer (50 mM, pH 7.1), and dialyzed (membrane cut off 10 KDa) against the same buffer for 48 h at 4 °C with four buffer changes. The dialyzed protein (2 mL) was then applied to a diethyl aminoethyl column (DEAE, HiPrep DEAE FF 16/10, Pharmacia, Sweden) pre-equilibrated with phosphate buffer (pH 7.1) through the GE AKTAprim plus system. The loaded protein was eluted with gradient NaCl solution (0–1000 mM) in phosphate buffer (pH 7.1) at a flow rate of 1 mL/min with a fraction size of 3 mL. The fractions revealing xylanase activity were collected, dialyzed, and concentrated through freeze drying. The xylanase activity and protein content in all fractions were evaluated and presented for each purification step. Furthermore, the purification progress was followed up through sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) at 12% polyacrylamide gel as adapted from (Laemmli and Favre 1973).

Protein determination

Protein concentration was determined using direct measurement at a wavelength of 280 nm or according to the Folin-phenol reagent approach using bovine serum albumin (BSA) as the standard (Lowry et al. 1951).

Characterization of the partially purified Xylanase

Effect of temperatures on activity and stability of xylanase

The impact of temperature on xylanase activity was measured by incubating the partially purified enzyme with xylan at different incubation temperatures in the range of 20–90 °C for 10 min. Furthermore, the enzyme thermal stability was evaluated by incubating the purified enzymes without substrate at temperatures 20–90 °C for 60 min. Then, the xylanase activity was measured as mentioned above and expressed as residual activity (%) considering activity at 60 °C without prior temperature treatment as control (100%).

Effect of different pH values on the activity and stability of xylanase

To evaluate the effect of different pH values on the activity of partially purified xylanase, the birchwood xylan was prepared separately in the following buffers (50 mM): citrate buffer (pH: 3.0, 4.0, 5.0, and 6.0); sodium phosphate buffer (pH: 7.0 and 8.0); glycine–NaOH buffer (pH: 9.0, 10.0, 11.0, and 12.0). The xylanase activity was determined at each pH value as mentioned above. The xylanase stability at different pH values (3.0–12.0) was determined by pre-incubating the enzymes at these pH values for 1 h prior to activity determination. Afterward, the xylanase activity was measured as mentioned above and expressed as residual activity (%), considering activity without prior pH incubation as control (100%).

Effect of different metal ions on the activity and stability of xylanase

The effect of some metal ions, including Ba2+, Mg2+, Ca2+, Ni2+, Co2+, and Mn2+ cations with different concentrations, including (1.0, 5.0, and 10.0 mM), was determined on the partially purified xylanase activity compared with control without any additions (100% activity). In addition, the enzyme stability against the previous metal ions at different concentrations was evaluated by pre-incubating the enzymes with each metal ion for 60 min before activity determination. The enzyme activity was expressed as a residual activity (%) compared to the control (without additions), which is considered 100% activity.

Effect of different detergents and enzyme inhibitors on the activity and stability of xylanase

Xylanase activity was determined in the presence of some detergents (Tween-80, Urea, and H2O2) at different concentrations (1, 5, and 10%). Additionally, the effect of some enzyme inhibitors such as ethylenediaminetetraacetic acid disodium salt (EDTA-Na2), SDS, and dithiothreitol (DTT) on the activity of the partially purified enzymes was determined (at different concentrations 1.0–10.0 mM) and compared with the control (100% activity). The stability of xylanase against the same detergents and enzyme inhibitors was measured by pre-incubating the enzymes with each detergent or enzyme inhibitor for 60 min. The enzyme activity was expressed as a residual activity (%) compared to the control (without any additives) as 100% activity.

Effect of substrate concentration on xylanase activity and kinetics

The effect of substrate concentration upon enzyme activity was evaluated by measuring the xylanase activity at different concentrations of birchwood xylan (0.5–5%) at pH 8 (sodium phosphate buffer). Lineweaver–Burk plots were applied to deduct the reaction kinetic constants: Michaelis–Menten constant (Km) and maximum enzyme velocity (Vmax) according to (Lineweaver et al. 1934).

Evaluation of the antimicrobial activity of XOS

The antimicrobial activity of the prepared XOS was evaluated through the agar-well diffusion method against three human pathogens (Hudzicki 2009). The three applied pathogens: Staphylococcus aureus ATCC 25923 (S. aureus) as a Gram-positive bacterium, Escherichia coli ATCC 25922 (E. coli) as a Gram-negative bacterium, and Candida albicans ATCC 10231 (C. albicans) as a model for unicellular fungi were cultivated on Muller-Hinton broth for 24 h at 37 °C. The XOS samples were prepared by incubating birchwood xylan (1%, pH 7.1) with 40 µL of purified xylanase at 50 °C for different times: 15, 30, and 60 min. The agar-well diffusion was conducted through the separate distribution of 100 µL (0.5 McFarland) of each pathogen on Muller-Hinton agar plates. Under aseptic conditions, several wells (9 mm) were conducted on the agar surface and inoculated with 100 µL from each hydrolysis time. Non-hydrolyzed xylan and purified enzymes (100 µL) were also inoculated on each plate as negative controls. Additionally, two antimicrobial drugs, namely amoxicillin (AX-25, 25 mg/disk) and amphotericin-B (Am-B, 100 U/disk), were also included in the plates as positive controls for bacteria and fungi, respectively. All plates were incubated for 24 h at 37 °C, where the developed halo-zones around the wells indicated antimicrobial activity.

Statistical analysis

The data included thought the current study are means (M) of three replicas with standard deviation (SD) from means represented as column with error bar in histograms or M ± SD in tables. Additionally, the cell size (length and width) of the potent xylanase-producing isolate was retrieved from the scanning electron microscopy (SEM) images through ImageJ software.

Results and discussion

Isolation and screening for xylanase activity

In the course of xylanase production screening, four serially diluted samples were inoculated separately on XA plates. Ninety-five separate bacterial colonies were detected on the XA plate’s surfaces, with about six colonies revealing clear zones (Halo-zones) around the bacterial growth (Fig. 1A).

Furthermore, the xylanase production potential of the six bacterial isolates (ARSE1-ARSE6) revealing halo-zones on XA plates was confirmed through quantitative xylanase determination. The results (Fig. 1B) asserted xylanase production ability for all examined bacterial isolates with varied production titers. Isolate coded ARSE6 reported the lowest xylanase production about 82 U/mL, where the most potent xylanase producer was isolate coded ARSE2 (221.69 U/mL). This variation in the production titer indicated the importance of screening and strain selection for enzyme production improving. Based on the quantitative xylanase determination, isolate ARSE2 was selected as most potent for the optimization of xylanase production and further studies.

Several phenotypic characteristics for the potent xylanase-producing isolate (ARSE2) were evaluated. Under electron microscopy, the bacterium was diplobacilli (Fig. 2A, B) with average dimensions of 1.64 and 0.69 µm for cell length and width, respectively (Fig. 2C, D).

Additionally, the results (Fig. 3A) indicated that the isolate coded ARSE2 was Gram-positive, motile, spore-forming, facultative aerobic, and rod shape bacillus species. The ARSE2 isolate revealed a significant ability to degrade complex substrates, such as starch, gelatin, and CMC, indicating amylases, proteases, and cellulases activities. Furthermore, the ARSE2 isolate was also able to assimilate a wide range of simple sugars, except ribose and raffinose. At the molecular level, the genomic DNA of the potent xylanases-producing isolate (ARSE2) was isolated and the 16S rRNA gene was amplified. The 16S rRNA sequence was aligned against 16S rRNA sequences of Gen Bank (http://blast.ncbi.nlm.nih.gov/Blast.cgi) through the BLAST algorithm where the gene homology revealed close relation to Bacillus subtilis subsp. subtilis strain ARSE2, with a similarity of 99% and accession number ON038356.1. The phylogenetic relationship confirmed the close relatedness of the locally isolated ARSE2 to Bacillus subtilis species as indicated in Fig. 3B.

A Is the morphological and biochemical characterization of the locally isolated Bacillus subtilis ARSE2 where M.R. methyl red test and V.P. Voges–Proskauer test. B is the phylogenetic relationship of the isolate ARSE2 through the neighbor-joining method and based on Jukes–Cantor distances. The phylogenetic analysis was performed by comparing the 16S rRNA sequence for isolated ARSE2 to reference strains using the MEGA 6 software

Optimization of xylanase production

Effect of different carbon sources on xylanase production

The carbon source is an essential constituent of the fermentation medium, which affects cell growth and metabolic activity. Hence, the effect of various carbon sources on xylanase production by Bacillus subtilis ARSE2 was investigated. The results (Fig. 4A) revealed that birchwood xylan supported the highest xylanase production of about 293.86 U/mL (OD600 2.113), followed by CMC and starch with enzyme productivity of 152.87 and 130.09 U/mL, respectively. On the other hand, the other applied carbon sources supported very low xylanase productivity, where the lowest production was about 72 U/mL through ribose. Xylanases are inducible enzymes, largely induced by the soluble catabolites generated from xylan degradation (Gaur et al. 2015; Shakoori et al. 2015). The results indicated growth-independent xylanase production. The highest cell mass (OD600 2.315) was detected from glucose associated with a very low xylanase production (92.92 U/mL), which could be attributed to feedback inhibition (Maulana Hidayatullah et al. 2020).

Optimization of the nutritional conditions for maximum xylanase production by Bacillus subtilis ARSE2, including the effect of different carbon sources on xylanase production (A), the effect of different nitrogen sources on xylanase production (B), different concentrations of the optimum nitrogen source (peptone) (C), and the effect of different NaCl concentrations on xylanase production

Effect of different nitrogen sources on xylanase production

The nature and concentration of nitrogen sources directly affect cell growth and enzyme production. The results (Fig. 4B) revealed that organic nitrogen sources such as peptone showed the maximum xylanase activity of about 174.93 U/mL, followed by beef extract and tryptone (169.89 and 157.42 U/mL, respectively). Additionally, some inorganic nitrogen sources, such as (NH4)2SO4, NaNO3, and NH4H2PO4, supported a significant titer of xylanase of about 150.95, 147.35, and 137.28 U/mL, respectively. These results agree with the other studies that reported an enhancement in xylanase production in Bacillus sp. through organic nitrogen sources (Otero et al. 2021; Bakry et al. 2022), which could be attributed to their high content of vitamins and minerals required for better growth and enzyme production. In contrast, other studies found that inorganic nitrogen sources increased xylanase production (Kallel et al. 2016; Pasalari and Homaei 2022). The highest cell mass (OD600 1.669) was supported by yeast extract, but the xylanase production was 142.80 U/mL, which is in line with the previous carbon source results.

Additionally, the effect of different concentrations of peptone on xylanase production by Bacillus subtilis ARSE2 is illustrated in Fig. 4C. The xylanase production and stain growth increased with the increase in peptone concentrations, where the highest productivity (224.80 U/mL) and cell growth (OD600 2.320) were at 1.4% peptone. The xylanase production and bacterial growth slightly decreased after this concentration to reach 149.749 U/mL and 1.631 (OD600), respectively, at 6% of the peptone concentration.

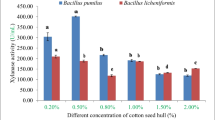

Effect of NaCl concentrations on xylanase production

Bacterial growth and xylanase productivity increased gradually when the concentration of sodium chloride was increased (Fig. 4D). The maximum xylanase production (287.39 U/mL) was at 5% NaCl, while the highest cell mass was at 3% NaCl (OD600 1.201). The optimum NaCl concentration for maximum xylanase production is strain-dependent, as supplementation with 2% NaCl (w/v) showed the highest xylanase production by Bacillus pumilus LRF1X (Banerjee and Ghosh 2016), whereas 0.8% NaCl (w/v) was optimum for Bacillus megaterium BM07 (Irfan et al. 2016). Both bacterial growth and xylanase production by Bacillus subtilis ARSE2 were gradually reduced when the NaCl concentration increased above 5%, which could be attributed to increased osmotic pressure (Wang et al. 2010).

Effect of different metals and amino acids on xylanase production

Metal ions are known to play a crucial role in enzyme activity as cofactors. Hence, the effects of various metal ions (K+, Ca2+, Ni2+, Ba2+, Co2+, Mg2+, and Cu2+) on xylanase production were examined as compared to the control (metal-free). The results (Fig. 5A) revealed that xylanase productivity was enhanced in the presence of Ca2+, Ba2+, and Co2+, whereas the maximum enzyme production of 234.88 U/mL was detected by the K+ ion compared to the control (203.94 U/mL). These results are in agreement with Tiwari et al. (2022) reported enhancement of xylanase production through the Co2+ ion. On the other hand, Ni2+, Mg2+, and Cu2+ reduced the xylanase production to 90.28, 200.11, and 66.78 U/mL, respectively, which is in accordance with the other studies (Lai et al. 2021; Tiwari et al. 2022). This may be due to its interaction with sulfhydryl groups, suggesting that there is an important cysteine residue in or close to the active site of the enzyme (Ajsuvakova et al. 2020). Regarding cell mass production, all applied metal ions exhibited an inhibitory effect on cell growth compared to the control.

Furthermore, the effect of various amino acids on xylanase production was evaluated and is represented in Fig. 5B. Compared to the control, both bacterial growth and xylanase productivity were enhanced with all of the studied amino acids, with maximum enzyme production by tryptophan (223.84 U/mL), followed by glutamic acid (218.57 U/mL), and cysteine (211.62 U/mL). Lysine revealed the lowest xylanase induction potential, about 152.8 U/mL, with approximately no difference from the control.

Effect of cultivation temperatures and pH on xylanase production

The effect of different temperatures (20–60 °C) was studied for maximal xylanase production by Bacillus subtilis ARSE2. The results (Fig. 6A) revealed a gradual increase in xylanase production at a temperature range of 20–30 °C, with maximum enzyme production (391.46 U/mL) at 30 °C. Afterward, xylanase productivity gradually decreased with increasing temperature (35–60 °C), with the lowest xylanase activity (89.80 U/mL) at 60 °C. According to the literature, the optimum temperature for xylanase production ranged between 30 and 60 °C, depending on the producing strain (Irfan et al. 2016; Ketsakhon et al. 2022). Furthermore, the bacterial growth was gradually increased with temperature and maximized at 40 °C (OD600 3.091). At temperatures above 40 °C, the growth rate abruptly decreased.

On the other hand, medium pH significantly affected various enzymatic processes and nutrient transportation through the cell membrane (Kapoor et al. 2008). Hence, the effect of different pH values on xylanase production by Bacillus subtilis ARSE2 was evaluated, as represented in Fig. 6B. The results revealed significant xylanase production in a slightly acidic-to-alkaline medium at a pH range of 5–10. The maximum enzyme production was at pH 8 (240.63 U/mL), which is consistent with the other studies (Irfan et al. 2016; Danso et al. 2022). The enzyme productivity was dramatically retarded in extremely acidic (pH 3–4) and hyperalkaline (pH 11) media, which could be related to enzyme denaturation. On the other hand, bacterial growth significantly increased from pH 3 to 9, with maximum growth at pH 8.

Effect of inoculum size and incubation period on xylanase production

The effect of different inoculum sizes of Bacillus subtilis ARSE2 upon xylanase production was evaluated. The results (Fig. 7A) revealed that the optimum inoculum size was 6%, with a maximum enzyme productivity of about 276.84 U/mL. Lower or higher inoculum sizes (more or less 6%) reduced xylanase production, which could be attributed to an insufficient number of bacteria or rapid depletion of nutrients in the fermentation medium (Battan et al. 2007; Omojasola et al. 2008).

The optimum cultivation time for maximum enzyme production is likely to depend on several factors, including the strain type and cultivation requirements (Danso et al. 2022). In the present study (Fig. 7B), xylanase production started during the log phase, and its levels increased gradually during the fermentation course, with maximum xylanase production occurring at 48 h (about 490 U/mL). Prolonged incubation decreased enzyme activity (about 374.8 U/mL after 108 h), which could be attributed to the proteolysis of the enzyme and/or the production of toxic metabolites (Maulana Hidayatullah et al. 2020). These results are in agreement with the other studies that reported maximum xylanase production at 48 h from several Bacillus sp. (Irfan et al. 2016; Malhotra and Chapadgaonkar 2021). On the other hand, the bacterial growth increased over time to a maximum (OD600 1.994) after 36 h. The cells maintained a stationary growth between 36 and 60 h of fermentation and then declined.

Application of lignocellulosic wastes for sustainable xylanase production

Commercial xylanase production implies a reduction in the medium cost and operation condition requirements (Bajar et al. 2020). The effect of alkali-pre-treated agro-industrial wastes on xylanase production by Bacillus subtilis ARSE2 through SSF or SF fermentation approaches was investigated. The results of SSF (Table 1) revealed that all tested wastes supported xylanase production at different titers. The maximum xylanase production was through sugarcane bagasse (472.03 U/mL) under SSF conditions. Accordingly, enhanced xylanase production employing multiple agricultural substrates, as well as high levels of enzyme production at lower substrate-to-moisture ratios, have previously been reported (Ketsakhon et al. 2022; Kaur et al. 2023). Sugarcane bagasse is an inexpensive byproduct with high xylan content; therefore, it is one of the most utilizable components of media for xylanase production (Alokika and Singh 2020; Moran-Aguilar et al. 2021). The other wastes also supported varied xylanase production, where sawdust reported the minimum xylanase production (243.03 U/mL).

On the other hand, the SF results revealed that sawdust was found to be the most suitable substrate for maximum xylanase production by Bacillus subtilis ARSE2, followed by sugarcane bagasse, with activities of 485.70 and 464.83 U/mL, respectively. Currently, the implementation of pre-treated agricultural residues is widely reported for sustainable xylanase production, including rice straw, wheat straw, sugarcane bagasse, wheat bran, oat husk, rice husk, rice bran, and oat wheat (Bajar et al. 2020; Shakir et al. 2020; Danso et al. 2022).

Purification of the xylanase enzyme produced by Bacillus subtilis ARSE2

For xylanase purification, the CFS (150 mL) was concentrated by (NH4)2SO4 (75% saturation) and applied to the DEAE column. As indicated in the purification results (Table 2), the protein content in the CFS (2750.7 mg) was decreased to 91.5 mg upon (NH4)2SO4 precipitation and dialyses. Application of (NH4)2SO4 increased the xylanase purity 7.5-fold compared to the crude enzyme. The DEAE-column chromatogram (Fig. 8A) revealed several protein peaks in the applied dialyzed sample, where xylanase activity was detected at fractions 9–14, with maximum activity at fractions 10–13. The DEAE-column application enhanced the specific activity of xylanase to 348.8 U/mg compared to CFS (27.95 U/mg), which indicated a significant reduction in untargeted protein. The results indicated a 12.5-fold increase in the xylanase protein purity compared to CFS (Table 2). The SDS-PAGE (12%) results confirmed the purification progress, where two protein bands were detected after DEAE-column application at 42 and 30 KDa (Fig. 8B).

Purification chromatogram of xylanase on DEAE column (A) revealing protein concentration and xylanase activity (U/mL) as eluted with NaCl gradient (mM), whereas (B) is the SDS-PAGE representing the purification progress, including lane M: protein marker, lane 1: crude enzyme, lane 2: ammonium sulfate precipitation, and lane 3: DEAE-column results

Characterization of the partially purified xylanase

Effect of temperatures on xylanase activity and stability

The optimum temperature for partially purified xylanase activity was evaluated at 20–90 °C. As shown in Fig. 9A, the xylanase enzyme was active over a wide temperature range. The maximum enzyme activity was at 60–70 °C (about 980.14 U/mL), which is in agreement with the other studies that reported the same temperature for optimum xylanase activity from several Bacillus sp. (Dheeran et al. 2012; Saleem et al. 2012). Increasing the reaction temperatures over 70 °C gradually reduced the xylanase activity, with a minimum activity at 90 °C of about 625.73 U/mL.

Additionally, the thermal stability study (Fig. 9A) revealed the high stability of the purified xylanase, as indicated by retaining over 97.4% of its hydrolytic activity after 60 min of incubation at a temperature of 20–60 °C. Temperatures above 60 °C decreased the enzyme stability significantly, with more than 55- and 80% of enzyme activity loss at 80- and 90 °C, respectively. The thermal stability of Bacillus subtilis ARSE2 xylanase in the current study is comparable to that of Thermobifida halotolerans YIM 90462 (Zhang et al. 2012) and Geobacillus sp. WBI xylanases, which revealed 0% relative activity after 30–60 min at 80 °C (Mitra et al. 2015).

Effect of different pH values on xylanase activity and stability

The effect of pH on xylanase activity was evaluated at different pH values (3–12). As shown in Fig. 9B, the studied xylanase was active in a wide pH range (acidic–alkaline), with more than 41% of its activity at a pH between 4.0 and 11.0. The optimum pH value for xylanase activity was 8.0, which is in line with several studies (Patel and Dudhagara 2020b; Shakir et al. 2020). However, other pH values for optimum xylanase activity were also reported (Bakry et al. 2022; Tiwari et al. 2022). The enzyme activity was negatively affected by pH values less than 5 or greater than 9.

The stability of partially purified xylanase at the previous pH values was also evaluated. The results (Fig. 9B) indicated that the partially purified xylanase revealed significant stability in the pH range 4–11 (about 67.23% and 81.7%, respectively), which is in line with optimum pH value results. The maximum enzyme stability was at pH 8–9 (about 95%), which indicated the suitability of isolate enzymes for pulping and food industries that carried on at high pH values (Kumar et al. 2014; Lai et al. 2021). These results are in agreement with those reported by Chivero et al., who reported that xylanase from the genus Bacillus has an optimum pH of 8.0 and is stable in a wide pH range of 6.0–9.0 (Chivero et al. 2001).

Effect of different metal ions on the activity and stability of xylanase

Inhibition of xylanase activity through metal ions accumulated in woody and agricultural residues is a major challenge for enzyme application in the pulping process (Poornima et al. 2020). Hence, the effects of Ba2+, Mg2+, Ca2+, Ni2+, Co2+, and Mn2+ at different concentrations on the activity and stability of partially purified xylanase were evaluated and are presented in Table 3. The xylanase activity and stability were slightly enhanced with Ba2 and Co2+ ions compared to the control. At 1 mM concentration, the Ba2 and Co2+ ions enhanced both xylanase activity and stability to 101.5 and 111.69%, respectively (with Ba2) and 116.4 and 129.36%, respectively (with Co2+). Furthermore, Mg2+ and Mn2+ ions enhanced the xylanase activity, but the enzyme stability was adversely affected. The maximum enzyme activity was 137% at 5 mM of MgCl2, whereas the enzyme stability decreased to 82.4% when incubated for 1 h with Mg2+ at 10 mM. Also, Mn2+ ions enhanced the enzyme activity to 111.15 at 1 mM, with a maximum reduction in the enzyme stability (about 30%) at 10 mM compared to the control. The results are in accordance with several studies that have reported the enhancement of xylanase activity with Mn2+ ions (Bataillon et al. 2000; Kiddinamoorthy et al. 2008). The Ca2+ ions revealed no significant effects on both xylanase activity and stability, as the maximum enzyme activity was 101.95% (at 1 mM), while the minimum stability (99.61%) was at 10 mM. Among the studied metals, the Ni2+ ions moderately affected the xylanase activity and stability by 76.5% and 93.3%, respectively, at a concentration of 10 mM.

Effect of some detergents and enzyme inhibitors on the activity and stability of the partially purified xylanase

The effects of some detergents and enzyme inhibitors on xylanase activity and stability were evaluated at different concentrations. As shown in Table 3, xylanase activity and stability were enhanced through tween-80 and DTT. Tween-80 supported the maximum enzyme activity and stability of about 126.1% and 117.5%, respectively, followed by DTT (108% and 110.7%, respectively), at the same concentration (10%). The results are in line with several previous studies (Park et al. 2012; Wang et al. 2022). The enhancement in xylanase activity and/or stability through DTT could be related to its role in stabilizing the conformational folding of the enzyme by prohibiting disulfide bond formation at the irregular position of the protein (Vieira et al. 2007).

On the other hand, SDS, EDTA, urea, and H2O2 adversely affected both enzyme activity and stability at all applied concentrations. H2O2 severely affected xylanase activity and stability, with complete enzyme inhibition at concentrations greater than 1%. The SDS negative effect comes next to H2O2, where xylanase activity and stability were reduced to about 30% and 14%, respectively, at 10 mM SDS. The xylanase stability toward SDS in the current study (99.7% at 1% SDS) is comparable to that of Geobacillus thermodenitrificans xylanase, which retains 72% activity at 0.5% SDS (Verma et al. 2013), and to Paenibacillus sp. NF1 (Zheng et al. 2014), which is significantly inhibited even at 0.02% SDS. In the same regard, the increase in EDTA concentration reduced both xylanase activity and stability to 80.9% and 78.1%, respectively, at a 10 mM concentration. The inhibition of Bacillus subtilis ARSE2 xylanase activity in the presence of EDTA suggests that metals are desirable for the optimum enzymatic reaction, confirming the metalloprotein nature of the enzyme (Khandeparkar and Bhosle 2006), which is in line with the enhancement in the xylanase activity in the presence of CoCl2 and MgCl2 (Table 3). Furthermore, the inhibition of xylanase activity through EDTA has been widely reported (Amobonye et al. 2021; Olopoda et al. 2022).

Effect of substrate concentrations on xylanase activity and kinetics

The effect of different concentrations of birchwood xylan (0.5–5.0%) on partially purified xylanase activity was studied. The results (Fig. 10) showed that xylanase activity increased gradually as substrate concentration increased from 0.5 to 2%, with maximum xylanase activity (1429.03 U/mL) at 2.5% of the birchwood xylan concentration. Afterward, the increase in the birchwood xylan concentration insignificantly affected the enzyme activity, indicating a substrate saturation state. The Lineweaver–Burk plot (Fig. 10) represented the relationship between enzyme velocity and substrate concentration, where Km and Vmax values could be deduced based on the Michaelis–Menten kinetics model. The results indicated that Vmax was 1481.5 U/mL when the Km constant was 0.187 mM. The very low Km value (0.187 mM) indicated the high affinity and efficiency of xylanase from Bacillus subtilis ARSE2 to degrade xylan complex polysaccharide (Yadav et al. 2018; Tiwari et al. 2022).

Evaluation of XOS antimicrobial activity

The worldwide spread of multidrug-resistant bacteria has been a pressing human health challenge in recent decades (Thoma et al. 2022). Increased research toward novel antimicrobial drugs with lower resistant induction potential is mandatory (Murray et al. 2022). Hence, the antimicrobial activity of the prepared XOS at three hydrolysis times (15, 30, and 60 min) was evaluated against three human pathogens. The results (Fig. 11) indicated broad-spectrum antibacterial activity for the prepared XOS against S. aureus and E. coli. However, no antifungal activity was detected against C. albicans. The antibacterial activity was more significant for the applied Gram-positive (S. aureus) bacterium compared to the Gram-negative one (E. coli), which is in accordance with the other study (Christakopoulos et al. 2003). Additionally, the antibacterial activity was hydrolysis time-dependent, as indicated in Table 4. Increasing the hydrolysis time from 15 to 60 min increased the antimicrobial activity from 15.1 ± 1.2 to 20.7 ± 1.5 mm and 00 ± 00 to 13 ± 0.89 mm toward S. aureus and E. coli, respectively. Collectively, the results indicated that the potency of prepared XOS against S. aureus with antibacterial activity was higher than that of the amoxicillin reference drug (12.5 ± 0.98 mm). Sun et al. attributed this inhibition to the ability of XOS to interfere with and downregulate the pathogenicity and quorum-sensing genes in S. aureus ATCC 6538 (Sun et al. 2022). However, targeting the bacterial cell wall structure could be a part of this activity, which may be supported by higher activity in Gram-positive and the complete absence of antifungal activity toward C. albicans in the current study.

The antimicrobial activity of the XOS prepared through purified xylanase at three different hydrolysis times: 15 min (1), 30 min (2), and 60 min (3). Non-hydrolyzed xylan (Xylan) and purified xylanase (E) were also included. Two antimicrobial drugs, amoxicillin (AX-25) and amphotericin-B (Am-B), were included for bacteria and fungi, respectively

Conclusion

The increased worldwide demand for the efficient valorization of lignocellulosic materials for value-added products forces the continuous search for efficient lignocellulose-degrading enzymes with promising characteristics. In the current study, a local strain (ASRE2) belonging to Bacillus subtilis revealed the highest xylanase titer (212.7 U/mL). The cultivation conditions directly influence the xylanase production, with maximum xylanase production (490.8 U/mL) at optimum conditions representing a 2.2-fold increase compared to the basal medium xylanase level (221.69 U/mL). Exploiting the lignocellulosic wastes for xylanase production reveals that the fermentation type directly influences the waste type and concentration for maximum enzyme production. Under solid-state fermentation, sugarcane bagasse (16% conc.) supported the maximum enzyme (472.03 U/mL), whereas woody sawdust had the highest enzyme titer of 485.70 under submerged fermentation. The produced enzyme was partially purified through the DEAE column to about 12.5 purification fold, where the purified enzyme revealed strong thermal and pH stability with remarkable stability toward several detergents and enzyme inhibitors, which encourages its implementation in several industrial applications. Additionally, the XOS resulting from xylan hydrolysis with the purified enzyme revealed significant broad-spectrum antibacterial activity, especially toward S. aureus, which paves the way for intensifying the research in this direction toward novel antimicrobial agents. The current study asserts the applicability of xylanases from locally isolated Bacillus subtilis for industrial applications and the production of biologically active XOS. However, further research is required to determine the enzyme's exact molecular weight and identify the nature of biologically active XOS and their mechanisms of action.

Data availability

All datasets used/or analyzed during the current study are available from the corresponding authors on reasonable request.

References

Ajsuvakova OP, Tinkov AA, Aschner M et al (2020) Sulfhydryl groups as targets of mercury toxicity. Coord Chem Rev 417:213343. https://doi.org/10.1016/j.ccr.2020.213343

Alokika SB (2020) Enhanced production of bacterial xylanase and its utility in saccharification of sugarcane bagasse. Bioprocess Biosyst Eng 43:1081–1091. https://doi.org/10.1007/s00449-020-02306-8

Amobonye A, Bhagwat P, Singh S, Pillai S (2021) Beauveria bassiana xylanase: characterization and wastepaper deinking potential of a novel glycosyl hydrolase from an endophytic fungal entomopathogen. J Fungi 7:668

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270. https://doi.org/10.1016/0168-1656(92)90074-J

Bajar S, Singh A, Bishnoi NR (2020) Exploration of low-cost agro-industrial waste substrate for cellulase and xylanase production using Aspergillus heteromorphus. Appl Water Sci 10:1–9. https://doi.org/10.1007/s13201-020-01236-w

Bakry MM, Salem SS, Atta HM et al (2022) Xylanase from thermotolerant Bacillus haynesii strain, synthesis, characterization, optimization using Box - Behnken Design, and biobleaching activity. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-03043-6

Banerjee S, Ghosh K (2016) Bio-processing of linseed oil-cake through solid state fermentation by non-starch polysaccharide degrading fish gut bacteria. J Ferment Technol 5:1–10

Basit A, Jiang W, Rahim K (2020) Xylanase and its industrial applications. Biotechnological applications of biomass. IntechOpen

Bataillon M, Cardinali A-PN, Castillon N, Duchiron F (2000) Purification and characterization of a moderately thermostable xylanase from Bacillus sp. strain SPS-0. Enzyme Microb Technol 26:187–192

Battan B, Sharma J, Dhiman SS, Kuhad RC (2007) Enhanced production of cellulase-free thermostable xylanase by Bacillus pumilus ASH and its potential application in paper industry. Enzyme Microb Technol 41:733–739

Biswas R, Sahai V, Mishra S, Bisaria VS (2010) Bioprocess strategies for enhanced production of xylanase by Melanocarpus albomyces IITD3A on agro-residual extract. J Biosci Bioeng 110:702–708

Cekmecelioglu D, Demirci A (2020) Production of cellulase and xylanase enzymes using distillers dried grains with solubles (DDGS) by Trichoderma reesei at shake-flask scale and the validation in the benchtop scale bioreactor. Waste Biomass Valoriz 11:6575–6584. https://doi.org/10.1007/s12649-020-00934-5

Chakdar H, Kumar M, Pandiyan K et al (2016) Bacterial xylanases: biology to biotechnology. 3 Biotech 6:1–15

Chivero ET, Mutukumira AN, Zvauya R (2001) Partial purification and characterisation of a xylanase enzyme produced by a micro-organism isolated from selected indigenous fruits of Zimbabwe. Food Chem 72:179–185

Christakopoulos P, Katapodis P, Kalogeris E et al (2003) Antimicrobial activity of acidic xylo-oligosaccharides produced by family 10 and 11 endoxylanases. Int J Biol Macromol 31:171–175

Danso B, Ali SS, Xie R, Sun J (2022) Valorisation of wheat straw and bioethanol production by a novel xylanase- and cellulase-producing Streptomyces strain isolated from the wood-feeding termite, Microcerotermes species. Fuel 310:122333. https://doi.org/10.1016/j.fuel.2021.122333

Devi A, Bajar S, Kour H et al (2022) Lignocellulosic biomass valorization for bioethanol production: a circular bioeconomy approach. Bioenergy Res. https://doi.org/10.1007/s12155-022-10401-9

Dheeran P, Nandhagopal N, Kumar S et al (2012) A novel thermostable xylanase of Paenibacillus macerans IIPSP3 isolated from the termite gut. J Ind Microbiol Biotechnol 39:851–860

Gaur R, Tiwari S, Rai P, Srivastava V (2015) Isolation, production, and characterization of thermotolerant xylanase from solvent tolerant Bacillus vallismortis RSPP-15. Int J Polym Sci 2015:986324

Ghosh A, Chandra A, Dhar A et al (2021) Multi-efficient thermostable endoxylanase from Bacillus velezensis AG20 and its production of xylooligosaccharides as efficient prebiotics with anticancer activity. Process Biochem 109:59–71

Golgeri M DB, Mulla SI, Bagewadi ZK, et al (2022) A systematic review on potential microbial carbohydrases: current and future perspectives. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2022.2106545

Gowdhaman D, Manaswini VS, Jayanthi V et al (2014) Xylanase production from Bacillus aerophilus KGJ2 and its application in xylooligosaccharides preparation. Int J Biol Macromol 64:90–98. https://doi.org/10.1016/j.ijbiomac.2013.11.012

Hudzicki J (2009) Kirby-Bauer disk diffusion susceptibility test Protocol. American society for microbiology, pp 55–63

Irfan M, Asghar U, Nadeem M et al (2016) Optimization of process parameters for xylanase production by Bacillus sp. in submerged fermentation. J Radiat Res Appl Sci 9:139–147. https://doi.org/10.1016/j.jrras.2015.10.008

Kallel F, Driss D, Chaari F et al (2016) Statistical optimization of low-cost production of an acidic xylanase by Bacillus mojavensis UEB-FK: its potential applications. Biocatal Agric Biotechnol 5:1–10. https://doi.org/10.1016/j.bcab.2015.11.005

Kapoor M, Nair LM, Kuhad RC (2008) Cost-effective xylanase production from free and immobilized Bacillus pumilus strain MK001 and its application in saccharification of Prosopis juliflora. Biochem Eng J 38:88–97

Kaur P, Khatri M, Singh G et al (2023) Xylopentose production from crop residue employing xylanase enzyme. Bioresour Technol 370:128572. https://doi.org/10.1016/j.biortech.2022.128572

Ketsakhon P, Thammasittirong A, Thammasittirong SN-R (2022) Adding value to rice straw waste for high-level xylanase production using a new isolate of Bacillus altitudinis RS3025. Folia Microbiol (praha). https://doi.org/10.1007/s12223-022-00998-x

Khandeparkar R, Bhosle NB (2006) Purification and characterization of thermoalkalophilic xylanase isolated from the Enterobacter sp. MTCC 5112. Res Microbiol 157:315–325

Kiddinamoorthy J, Anceno AJ, Haki GD, Rakshit SK (2008) Production, purification and characterization of Bacillus sp. GRE7 xylanase and its application in eucalyptus Kraft pulp biobleaching. World J Microbiol Biotechnol 24:605–612

Kumar L, Nagar S, Mittal A et al (2014) Immobilization of xylanase purified from Bacillus pumilus VLK-1 and its application in enrichment of orange and grape juices. J Food Sci Technol 51:1737–1749. https://doi.org/10.1007/s13197-014-1268-z

Laemmli UK, Favre M (1973) Maturation of the head of bacteriophage T4. I. DNA packaging events. J Mol Biol 80:575–599. https://doi.org/10.1016/0022-2836(73)90198-8

Lai Z, Zhou C, Ma X et al (2021) Enzymatic characterization of a novel thermostable and alkaline tolerant GH10 xylanase and activity improvement by multiple rational mutagenesis strategies. Int J Biol Macromol 170:164–177. https://doi.org/10.1016/j.ijbiomac.2020.12.137

Lineweaver H, Burk D, Deming WE (1934) The dissociation constant of nitrogen-nitrogenase in Azotobacter. J Am Chem Soc 56:225–230

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275. https://doi.org/10.1016/s0021-9258(19)52451-6

Malhotra G, Chapadgaonkar SS (2018) Production and applications of xylanases–an overview. Biotechnol J Biotechnol Comput Biol Bionanotechnol 99:59–72

Malhotra G, Chapadgaonkar SS (2021) Production of thermo-alkali-stable xylanase from Bacillus licheniformis isolated from natural hot water geyser. J Microsc Ultrastruct 9:131–135. https://doi.org/10.4103/JMAU.JMAU_21_20

Maulana Hidayatullah I, Setiadi T, Tri Ari Penia Kresnowati M, Boopathy R (2020) Xylanase inhibition by the derivatives of lignocellulosic material. Bioresour Technol 300:122740. https://doi.org/10.1016/j.biortech.2020.122740

Miao T, Basit A, Liu J et al (2021) Improved production of xylanase in pichia pastoris and its application in xylose production from xylan. Front Bioeng Biotechnol 9:690702

Mitra S, Mukhopadhyay BC, Mandal AR et al (2015) Cloning, overexpression, and characterization of a novel alkali-thermostable xylanase from Geobacillus sp. WBI J Basic Microbiol 55:527–537

Mmango-Kaseke Z, Okaiyeto K, Nwodo UU et al (2016) Optimization of cellulase and xylanase production by micrococcus species under submerged fermentation. Sustain 8:1168

Moran-Aguilar MG, Costa-Trigo I, Calderón-Santoyo M et al (2021) Production of cellulases and xylanases in solid-state fermentation by different strains of Aspergillus niger using sugarcane bagasse and brewery spent grain. Biochem Eng J 172:108060. https://doi.org/10.1016/j.bej.2021.108060

Murray CJ, Ikuta KS, Sharara F et al (2022) Global burden of bacterial antimicrobial resistance in 2019: a systematic analysis. Lancet 399:629–655. https://doi.org/10.1016/S0140-6736(21)02724-0

Olopoda IA, Lawal OT, Omotoyinbo OV et al (2022) Biochemical characterization of a thermally stable, acidophilic and surfactant-tolerant xylanase from Aspergillus awamori AFE1 and hydrolytic efficiency of its immobilized form. Process Biochem 121:45–55. https://doi.org/10.1016/j.procbio.2022.06.030

Omojasola PF, Jilani OP, Ibiyemi SA (2008) Cellulase production by some fungi cultured on pineapple waste. Nat Sci 6:64–79

Ontañon OM, Bedő S, Ghio S et al (2021) Optimisation of xylanases production by two Cellulomonas strains and their use for biomass deconstruction. Appl Microbiol Biotechnol 105:4577–4588. https://doi.org/10.1007/s00253-021-11305-y

Otero DM, Cavalcante Braga AR, Kalil SJ (2021) Diversification of nitrogen sources as a tool to improve endo-xylanase enzyme activity produced by Cryptococcus laurentii. Biocatal Agric Biotechnol 32:101941. https://doi.org/10.1016/j.bcab.2021.101941

Park N-J, Lim HK, Song HY et al (2012) Cloning, expression, and characterization of an alkalophillic endo-1, 4-beta-xylanase from Paenibacillus sp. Hpl-002. BioResources 7:727–742

Pasalari A, Homaei A (2022) Isolation and molecular identification of xylanase-producing bacteria from Ulva flexuosa of the Persian Gulf. Processes 10:1834

Patel K, Dudhagara P (2020a) Compatibility testing and enhancing the pulp bleaching process by hydrolases of the newly isolated thermophilic Isoptericola variabilis strain UD-6. Biocatal Biotransformation 38:144–160

Patel K, Dudhagara P (2020b) Optimization of xylanase production by Bacillus tequilensis strain UD-3 using economical agricultural substrate and its application in rice straw pulp bleaching. Biocatal Agric Biotechnol 30:101846

Poornima S, Divya P, Karmegam N et al (2020) Aqueous two-phase partitioning and characterization of xylanase produced by Streptomyces geysiriensis from low cost lignocellulosic substrates. J Biosci Bioeng 130:571–576. https://doi.org/10.1016/j.jbiosc.2020.07.008

Qeshmi FI, Homaei A, Fernandes P et al (2020) Xylanases from marine microorganisms: a brief overview on scope, sources, features and potential applications. Biochim Biophys Acta Proteins Proteom 1868:140312

Ramanjaneyulu G, Rajasekhar Reddy B (2016) Optimization of xylanase production through response surface methodology by Fusarium sp. BVKT R2 isolated from forest soil and its application in saccharification. Front Microbiol 7:1450

Saleem M, Aslam F, Akhtar MS et al (2012) Characterization of a thermostable and alkaline xylanase from Bacillus sp. and its bleaching impact on wheat straw pulp. World J Microbiol Biotechnol 28:513–522

Samanta AK, Kolte AP, Senani S et al (2011) A simple and efficient diffusion technique for assay of endo β-1,4-xylanase activity. Braz J Microbiol 42:1349–1353. https://doi.org/10.1590/S1517-838220110004000016

Shakir HA, Anwar A, Irfan M et al (2020) Statistical optimization of xylanase from Bacillus licheniformis using banana peels in submerged fermentation. Iran J Sci Technol Trans A Sci 44:981–991. https://doi.org/10.1007/s40995-020-00933-0

Shakoori FR, Shokat M, Saleem F, Reaz T (2015) Screening, optimization and characterization of xylanase by locally isolated bacteria. Punjab Univ J Zool 30:65–71

Šuchová K, Chyba A, Hegyi Z et al (2022) Yeast GH30 xylanase from sugiyamaella lignohabitans is a glucuronoxylanase with auxiliary xylobiohydrolase activity. Mol 27:751

Sun Z, Yue Z, Liu E, Li X, Li C (2022) Assessment of the bifidogenic and antibacterial activities of xylooligosaccharide. Front Nutr 9:858949. https://doi.org/10.3389/fnut.2022.858949

Sunkar B, Kannoju B, Bhukya B (2020) Optimized production of xylanase by Penicillium purpurogenum and ultrasound impact on enzyme kinetics for the production of monomeric sugars from pretreated corn cobs. Front Microbiol 11:1–13. https://doi.org/10.3389/fmicb.2020.00772

Thoma R, Seneghini M, Seiffert SN et al (2022) The challenge of preventing and containing outbreaks of multidrug-resistant organisms and Candida auris during the coronavirus disease 2019 pandemic: report of a carbapenem-resistant Acinetobacter baumannii outbreak and a systematic review of the literatu. Antimicrob Resist Infect Control 11:12. https://doi.org/10.1186/s13756-022-01052-8

Tiwari S, Singh R, Yadav J et al (2022) Three-step purification and characterization of organic solvent-tolerant and alkali-thermo-tolerant xylanase from Bacillus paramycoides T4 [MN370035]. Catal 12:749

Trejo M, Bhuyar P, Unpaprom Y et al (2022) Advancement of fermentable sugars from fresh elephant ear plant weed for efficient bioethanol production. Environ Dev Sustain 24:7377–7387. https://doi.org/10.1007/s10668-021-01753-x

Van Hoeck V, Somers I, Abdelqader A et al (2021) Xylanase impact beyond performance: a microbiome approach in laying hens. PLoS ONE 16:1–18. https://doi.org/10.1371/journal.pone.0257681

Vasić K, Knez Ž, Leitgeb M (2021) Bioethanol production by enzymatic hydrolysis from different lignocellulosic sources. Molecules 26:753

Verma D, Anand A, Satyanarayana T (2013) Thermostable and alkalistable endoxylanase of the extremely thermophilic bacterium Geobacillus thermodenitrificans TSAA1: cloning, expression, characteristics and its applicability in generating xylooligosaccharides and fermentable sugars. Appl Biochem Biotechnol 170:119–130

Vieira WB, de Moreira LRS, Monteiro Neto A, Ferreira Filho EX (2007) Production and characterization of an enzyme complex from a new strain of Clostridium thermocellum with emphasis on its xylanase activity. Braz J Microbiol 38:237–242

Wang C, Chan H, Lin H, Shyu Y (2010) Production, purification and characterisation of a novel halostable xylanase from Bacillus sp. NTU-06. Ann Appl Biol 156:187–197

Wang L, Wang Y, Chang S et al (2022) Identification and characterization of a thermostable GH11 xylanase from Paenibacillus campinasensis NTU-11 and the distinct roles of its carbohydrate-binding domain and linker sequence. Colloids Surf B Biointerfaces 209:112167. https://doi.org/10.1016/j.colsurfb.2021.112167

Yadav P, Maharjan J, Korpole S et al (2018) Production, purification, and characterization of thermostable alkaline xylanase from Anoxybacillus kamchatkensis NASTPD13. Front Bioeng Biotechnol 6:65. https://doi.org/10.3389/fbioe.2018.00065

Zhang F, Hu S-N, Chen J-J et al (2012) Purification and partial characterisation of a thermostable xylanase from salt-tolerant Thermobifida halotolerans YIM 90462T. Process Biochem 47:225–228

Zheng H, Sun M, Meng L et al (2014) Purification and characterization of a thermostable xylanase from Paenibacillus sp. NF1 and its application in xylooligosaccharides production. J Microbiol Biotechnol 24:489–496

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

HE-G: conceptualization, methodology, investigation, formal analysis, and writing—review and editing. ASB: conceptualization, methodology, investigation, formal analysis, and writing—review and editing. EKB: conceptualization, methodology, investigation, formal analysis, and writing—review and editing. MR: conceptualization, methodology, investigation, formal analysis, and writing—review and editing the final manuscript. SGA: writing—review and editing the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Communicated by PANKAJ BHATT.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Gendi, H., Badawy, A.S., Bakhiet, E.K. et al. Valorization of lignocellulosic wastes for sustainable xylanase production from locally isolated Bacillus subtilis exploited for xylooligosaccharides’ production with potential antimicrobial activity. Arch Microbiol 205, 315 (2023). https://doi.org/10.1007/s00203-023-03645-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00203-023-03645-2