Abstract

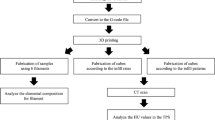

X-ray markers have been applied for diagnostic purposes in the medical imaging field. However, they were not flexible enough to accommodate the fast evolution of biomedical applications leading to a considerable performance gap. EHD-inkjet printing technique as a high-resolution, low-cost, and flexible approach was used to fabricate a silver X-ray marker to fill the gap in the biomedical field. Even though X-ray characterization of bulk silver had been studied, silver nanoink has presented a different X-ray absorption response. To understand the X-ray characterization of silver microstructures, multiple samples were fabricated. The EHD-inkjet printing system was applied to fabricate silver microstructures under optimized printing parameters, including voltage amplitude, pulse width, frequency, and printing speed. To understand X-ray characteristic differences between bulk silver and nanoink silver, experiments were designed to print a single layer and multiple layers of silver nanoink lines. Microstructures, which were e-jet printed by silver nanoink, presented different X-ray absorption rate to the bulk silver under the same radiation condition and thickness. Sub-30 μm microstructures of silver nanoink were achieved by e-jet printing; part of them will serve as the X-ray marker in bio-scaffold. This research proposed a method to bridge the e-jet printing technique with a customizable X-ray marker in bio-scaffold, which could effectively resolve the problem of flexibility, improve the resolution, and reduce the cost of manufacturing. Moreover, it supported the development of biomedical products that were fabricated by silver nanoink material, such as in vivo embedded biosensors in computed tomography applications.

Similar content being viewed by others

Availability of data and materials

The authors confirm that the data supporting the findings of this study are available within the article.

References

Bearden (1967) X-ray wavelengths. Rev Mod Phys 39(1):78

Mao H, Bell P, Shaner J (1978) Specific volume measurements of Cu, Mo, Pd, and Ag and calibration of the ruby R 1 fluorescence pressure gauge from 0.06 to 1. Mbar 49(6):3276–3283

Kim J, Kim WS (2014) Stretching silver: printed metallic nano inks in stretchable conductor applications. IEEE Nanotechnol Mag 8(4):6–13

Gniotek K, Frydrysiak M, Zięba J, Tokarska M, Stempień Z (2011) Innovative textile electrodes for muscles electrostimulation. IEEE International Symposium on Medical Measurements and Applications 305-310

Qin H, Dong J, Lee YS (2017) Fabrication and electrical characterization of multi-layer capacitive touch sensors on flexible substrates by additive e-jet printing. J Manuf Process 28:479–485

Yeo JC, Yap HK, Xi W, Wang Z, Yeow CH, Lim CT (2016) Flexible and stretchable strain sensing actuator for wearable soft robotic applications. Adv Mater Technol 1(3):1600018

Vimala K, Sivudu KS, Mohan YM, Sreedhar B, Raju KM (2009) Controlled silver nanoparticles synthesis in semi-hydrogel networks of poly (acrylamide) and carbohydrates: a rational methodology for antibacterial application. Carbohydr Polym 75(3):463–471

Lee SJ, Heo DN, Heo M, Noh MH, Lee D, Park SA, Moon JH, Kwon IK (2017) Most simple preparation of an inkjet printing of silver nanoparticles on fibrous membrane for water purification: technological and commercial application. J Ind Eng Chem 46:273–278

Sun Y, Wang Y (2011) Monitoring of galvanic replacement reaction between silver nanowires and HAuCl4 by in situ transmission X-ray microscopy. Nano Lett 11(10):4386–4392

Klaus T, Joerger R, Olsson E, Granqvist CG (1999) Silver-based crystalline nanoparticles, microbially fabricated. Proc Natl Acad Sci 96(24):13611–13614

Reed J, Eisenberger P, Teo BK, Kincaid BM (1977) Structure of the catalytic site of polymer-bound Wilkinson’s catalyst by X-ray absorption studies. J Am Chem Soc 99(15):5217–5218

Bukhtiyarov VI, Hävecker M, Kaichev VV, Knop-Gericke A, Mayer RW, Schlögl R (2011) X-ray absorption and photoemission studies of the active oxygen for ethylene epoxidation over silver. Catal Lett 74(3-4):121–125

Zhang F, Wu X, Chen Y, Lin H (2009) Application of silver nanoparticles to cotton fabric as an antibacterial textile finish. Fibers and Polymers 10(4):496–501

Perelaer J, De Gans BJ, Schubert US (2006) Ink-jet printing and microwave sintering of conductive silver tracks. Adv Mater 18(16):2101–2104

Ahn BY, Duoss EB, Motala MJ, Guo X, Park SI, Xiong Y, Yoon J, Nuzzo RG, Rogers JA, Lewis JA (2009) Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science. 323(5921):1590–1593

Lee HH, Chou KS, Huang KC (2005) Inkjet printing of nanosized silver colloids. Nanotechnology. 16(10):2436

Qin H, Cai Y, Dong J, Lee YS (2017) Direct printing of capacitive touch sensors on flexible substrates by additive E-jet printing with silver nanoinks. J Manuf Sci Eng 139(3)

Prieto PM, Vargas-Martın F, Goelz S, Artal P (2000) Analysis of the performance of the Hartmann–Shack sensor in the human eye. JOSA A 17(8):1388–1398

Moqrich A, Hwang SW, Earley TJ, Petrus MJ, Murray AN, Spencer KS, Andahazy M, Story GM, Patapoutian A (2005) Impaired thermosensation in mice lacking TRPV3, a heat and camphor sensor in the skin. Science. 307(5714):1468–1472

Wendel M, Kühn S, Lorenz H, Kotthaus JP, Holland M (1994) Nanolithography with an atomic force microscope for integrated fabrication of quantum electronic devices. Appl Phys Lett 65(14):1775–1777

Park SR, Peng H, Ling XS (2007) Fabrication of nanopores in silicon chips using feedback chemical etching. Small. 3(1):116–119

Schift H (2008) Nanoimprint lithography: an old story in modern times? A review. J Vac Sci Technol B 26(2):458–480

Levinson HJ (1999) Lithography process control. SPIE Press

Ye J, Pease RF, Chen X (2004) System and method for lithography process monitoring and control. United States patent US 6:828,542

Mishra S, Barton KL, Alleyne AG, Ferreira PM, Rogers JA (2010) High-speed and drop-on-demand printing with a pulsed electrohydrodynamic jet. J Micromech Microeng 20(9):095026

Han Y (2018) High-resolution electrohydrodynamic (EHD) 3D printing of function materials. North Carolina State University library, Ph.D. thesis

Qin H, Wei C, Dong J, Lee YS (2014) AC-pulse modulated electrohydrodynamic (EHD) direct printing of conductive micro silver tracks for micro-manufacturing. Flexible Automation and Intelligent Manufacturing, San Antonio

Han Y, Wei C, Dong J (2014) Super-resolution electrohydrodynamic (EHD) 3D printing of micro-structures using phase-change inks. Manuf Lett 2(4):96–99

Park J, Hwang J (2014) Fabrication of a flexible Ag-grid transparent electrode using AC based electrohydrodynamic jet printing. J Phys D Appl Phys 47(40):405102

Onses MS, Sutanto E, Ferreira PM, Alleyne AG, Rogers JA (2015) Mechanisms, capabilities, and applications of high-resolution electrohydrodynamic jet printing. Small. 11(34):4237–4266

Park J, Kim B, Kim SY, Hwang J (2014) Prediction of drop-on-demand (DOD) pattern size in pulse voltage-applied electrohydrodynamic (EHD) jet printing of Ag colloid ink. Applied Physics A 117(4):2225–2234

Wei C, Qin H, Ramirez-Iglesias NA, Chiu CP, Lee YS, Dong J (2014) High-resolution AC-pulse modulated electrohydrodynamic jet printing on highly insulating substrates. J Micromech Microeng 24(4):045010

Wei C, Qin H, Chiu CP, Lee YS, Dong J (2015) Drop-on-demand e-jet printing of continuous interconnects with AC-pulse modulation on highly insulating substrates. J Manuf Syst 37:505–510

Lee H, Seong B, Kim J, Jang Y, Byun D (2014) Direct alignment and patterning of silver nanowires by electrohydrodynamic jet printing. Small. 10(19):3918–3922

Han Y, Wei C, Dong J (2015) Droplet formation and settlement of phase-change ink in high resolution electrohydrodynamic (EHD) 3D printing. J Manuf Process 20:485–491

Coppola S, Vespini V, Grilli S, Ferraro P (2011) Self-assembling of multi-jets by pyro-electrohydrodynamic effect for high throughput liquid nanodrops transfer. Lab Chip 11(19):3294–3298

Yang SM, Lee YS, Jang Y, Byun D, Choa SH (2016) Electromechanical reliability of a flexible metal-grid transparent electrode prepared by electrohydrodynamic (EHD) jet printing. Microelectron Reliab 65:151–159

Bunker G (2010) Introduction to XAFS: a practical guide to X-ray absorption fine structure spectroscopy. Cambridge University Press

Funding

The project is sponsored by Dr. Qin’s startup funds and Undergraduate Research Assistant (URA) program from the Department of Industrial and Manufacturing Systems Engineering at Iowa State University. Their supports are appreciated.

Author information

Authors and Affiliations

Contributions

Conceptualization, X.Z., Z.Z., and H.Q.; methodology, X.Z., Z.Z., X.J., and H.Q.; software, X.Z.; validation, X.Z. and X.J.; formal analysis, X.Z. and X.J.; investigation, X.Z. and X.J.; resources, X.Z.; data curation, X.Z.; writing—original draft preparation, X.Z.; writing—review and editing, X.J., Y.C., Z.Z., and H.Q.; visualization, X.Z.; supervision, Z.Z. and H.Q.; project administration, Z.Z.; funding acquisition, H.Q. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

All procedures performed in studies, where applicable, were in accordance with the ethical standards of Iowa State University and/or national research committee and with the 1964 Helsinki declaration and its later amendments or comparable ethical standards.

Consent to participate

Informed consent was obtained from all individual participants included in the study.

Consent to publish

The participant has consented to the submission of the research to the journal.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, X., Jiang, X., Zhang, Z. et al. Fabrication of silver microstructures via electrohydrodynamic inkjet printing as customizable X-ray marker in bio-structure for biomedical diagnostic imaging. Int J Adv Manuf Technol 114, 241–250 (2021). https://doi.org/10.1007/s00170-021-06858-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06858-1