Abstract

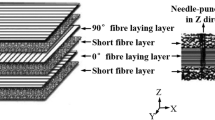

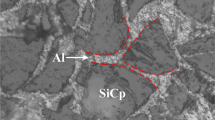

C/SiC composite material is widely used in aerospace fields because of its excellent properties; however, it is difficult to be removed and processed. In this paper, the 2.5-dimensional C/SiC composite material was ablated by nanosecond laser to explore the laser removal mechanism. Firstly, the laser ablation experiment was carried out to investigate the gradual process of ablation morphology with the increasing laser power density. Secondly, the characteristics of ablation holes were analyzed, and the effects of laser processing parameters and fiber orientation on the ablation morphology and size were studied. In addition, the ablation morphology of needle-punched fiber area was analyzed to expound the unique ablation removal characteristics of 2.5-dimensional C/SiC composites. At last, ablation removal mechanism of 2.5-dimensional C/SiC composites was summarized, and the model of ablation removal process was established. The results indicated that ablation morphology was evolved from nothing to ablation mark, to fiber expansion, to fiber shrinkage and tension, to resolidification, to removal holes, and to increasing holes with laser power density. Besides, the ablation morphology in needle-punched fiber area was different from elliptic ablation morphology in the 0° or 90° fiber area, the ablation holes in the needle-punched fiber area were smaller and deeper, and the ablation holes were approximately circular. The results would provide theoretical basis and technical support for processing functionalized structure of 2.5-dimensional C/SiC composites by nanosecond laser, such as blind holes, grooves, and square holes.

Similar content being viewed by others

Data availability

We confirm that data is open and transparent.

Change history

07 February 2021

A Correction to this paper has been published: https://doi.org/10.1007/s00170-021-06633-2

References

Wei K, Cheng X, He R, Pei Y, Fang D (2014) Heat transfer mechanism of the C/SiC ceramics pyramidal lattice composites. Compos B Eng 2014(63):8–14. https://doi.org/10.1016/j.compositesb.2014.03.015

Qu S, Gong Y, Yang Y, Cai M, Sun Y (2018) Surface topography and roughness of silicon carbide ceramic matrix composites. Ceram Int 44(12):14742–14753. https://doi.org/10.1016/j.ceramint.2018.05.104

Wang J, Ma Y, Liu Y, Wu Y, Hong S, Cheng H, Xiao Y (2019) Experimental investigation on laser ablation of C/SiC composites subjected to supersonic airflow. Opt Laser Technol 2019(113):399–406. https://doi.org/10.1016/j.optlastec.2019.01.019

Zhu W, Fu H, Xu Z, Rong L, Ping J, Xin S, Yu S, Chun Y (2018) Fabrication and characterization of carbon fiber reinforced SiC ceramic matrix composites based on 3D printing technology. J Eur Ceram Soc 38(14):4604–4613. https://doi.org/10.1016/j.jeurceramsoc.2018.06.022

Zhang L, Ren C, Ji C, Wang Z, Chen G (2016) Effect of fiber orientations on surface grinding process of unidirectional C/SiC composites. Appl Surf Sci 366(2016):424–431. https://doi.org/10.1016/j.apsusc.2016.01.142

Zhang L, Ren C, Zhou C, Xu H, Jin X (2015) Single fiber push-out characterization of interfacial mechanical properties in unidirectional CVI-C/SiC composites by the nano-indentation technique. Appl Surf Sci 357:1427–1433. https://doi.org/10.1016/j.apsusc.2015.10.018

Paulmier T, Balat-Pichelin M, Le Quéau D (2005) Structural modifications of carbon–carbon composites under high temperature and ion irradiation. Appl Surf Sci 243(1-4):376–393. https://doi.org/10.1016/j.apsusc.2004.09.106

He Z, Zhang L, Chen B, Liu Y, Liu X (2015) Failure behavior of 2D C/SiC I-beam under bending load. Compos Struct 132:321–330. https://doi.org/10.1016/j.compstruct.2015.04.066

Shumyacher VMO (2017) Energy Efficient technology of obtaining advanced composite grinding materials and tools in “Silicon Carbide – Corundum” system from aluminium-containing residual product. Procedia Eng 206(2017):228–231. https://doi.org/10.1016/j.proeng.2017.10.465

Ding K, Fu Y, Su H, Chen Y, Yu X, Ding G (2014) Experimental studies on drilling tool load and machining quality of C/SiC composites in rotary ultrasonic machining. J Mater Process Technol 214(12):2900–2907. https://doi.org/10.1016/j.jmatprotec.2014.06.015

Wang J, Zhang J, Feng P (2017) Effects of tool vibration on fiber fracture in rotary ultrasonic machining of C/SiC ceramic matrix composites. Compos Part B:S1359836816332644. https://doi.org/10.1016/j.compositesb.2017.07.081

Hashish M, Kotchon A, Ramulu M (2015) Status of AWJ machining of CMCS and hard materials INTERTECH 2015 - an Int. Tech Conf Diamond, Cubic Boron Nitride Their Appl 2015 August

Liu WC, Wei L, Li Z, Yang X (2014) Effect of energy density and feeding speed on micro-hole drilling in C/SiC composites by picosecond laser. Int J Adv Manuf Technol 214(12):3131–3140. https://doi.org/10.1016/j.jmatprotec.2014.07.016

Liu Q, Guo H, Xi X, Chong F, Chai C (2018) Influence of grinding fiber angles on grinding of the 2D–Cf /C–SiC composites. Ceram Int 44(11):12774–12782

Ramulu M, Jenkins G, Guo MZ (2001) Abrasive water jet machining mechanisms in continuous-fiber ceramic composites. Compos Technol Res 23(3):82–91. https://doi.org/10.1520/CTR10916J

Wei C, Zhao L, Hu D, Ni J (2013) Electrical discharge machining of ceramic matrix composites with ceramic fiber reinforcements. Int J Adv Manuf Technol 64(1–4):187–194

Zhai Z, Wang W, Zhao J, Xu M, Ke W, Fang W, Hui Y (2017) Influence of surface morphology on processing of C/SiC composites via femtosecond laser. Compos A: Appl Sci Manuf 102:117–125. https://doi.org/10.1016/j.compositesa.2017.07.031

Dong Y, Molian P (2003) Femtosecond pulsed laser ablation of 3CSiC thin film on silicon. Appl Phys A (Mater Sci Process) 77(6):839–846

Liu Y, Wang C, Li W, Yang X, Qing Z, Cheng L (2014) Effect of energy density on the machining character of C/SiC composites by picosecond laser. Appl Phys A 116(3):1221–1228

Li C, Shi X, Si J, Tao C, Feng C, Wu Z, Hou X (2008) Alcohol-assisted photoetching of silicon carbide with a femtosecond laser. Opt Commun 282(1):78–80. https://doi.org/10.1016/j.optcom.2008.09.072

Zhang Y, Wang Y, Zhang J, Yong L, Yang X (2016) Effects of laser repetition rate and fluence on micromachining of TiC ceramic. Mater Manuf Process 31(7):832–837. https://doi.org/10.1080/10426914.2015.1037916

Nayak BK, Gupta MC (2010) Ultrafast laser-induced self-organized conical micro/nano surface structures and their origin. Opt Lasers Eng 48(10):966–973. https://doi.org/10.1016/j.optlaseng.2010.05.009

Glass D (2008) Ceramic matrix composite (CMC) thermal protection systems (TPS) and hot structures for hypersonic vehicles. Int Space Planes Hyperson Syst Technol Conf 2008:2682

Li W, Zhang R, Liu Y, Chun W, Wang J, Xiao Y, Lai C (2016) Effect of different parameters on machining of SiC/SiC composites via pico-second laser. Appl Surf Sci 364:378–387. https://doi.org/10.1016/j.apsusc.2015.12.089

Appleby MP, Zhu D, Morscher GN (2015) Mechanical properties and real-time damage evaluations of environmental barrier coated SiC/SiC CMCs subjected to tensile loading under thermal gradients. Surf Coat Technol 284:318–326. https://doi.org/10.1016/j.surfcoat.2015.07.042

Zhai Z, Wang W, Mei X, Ming L, Jian C, Fang W, Ai P (2018) Effect of the surface microstructure ablated by femtosecond laser on the bonding strength of EBCs for SiC/SiC composites. Opt Commun 424:137–144. https://doi.org/10.1016/j.optcom.2018.04.055

Zhai Z, Wei C, Zhang Y, Cui Y, Zeng Q (2020) Investigations on the oxidation phenomenon of SiC/SiC fabricated by high repetition frequency femtosecond laser. Appl Surf Sci 502:144131. https://doi.org/10.1016/j.apsusc.2019.144131

Hu M, Ming W, An Q, Chen M (2019) Experimental study on milling performance of 2D C/SiC composites using polycrystalline diamond tools. Ceram Int 45(8):10581–10588. https://doi.org/10.1016/j.ceramint.2019.02.124

Funding

This work was supported by the National Natural Science Foundation of China [GrantNo.51705148].

Author information

Authors and Affiliations

Contributions

Haowen Jiao contributed to the conceptualization, investigation, writing of the original draft, writing of the review, and editing.

Bing Chen contributed to the writing of the review, editing, and funding acquisition.

Shichun Li contributed to the review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have competing interests.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Figures 6 and 7 images are the same.

Rights and permissions

About this article

Cite this article

Jiao, H., Chen, B. & Li, S. Removal mechanism of 2.5-dimensional carbon fiber reinforced ceramic matrix composites processed by nanosecond laser. Int J Adv Manuf Technol 112, 3017–3028 (2021). https://doi.org/10.1007/s00170-020-06499-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06499-w