Abstract

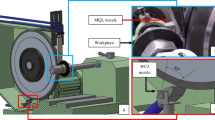

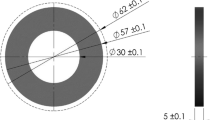

The application of the minimum quantity lubrication (MQL) technique in grinding processes is still limited due to the frequent occurrence of overheating and wheel clogging. In this context, this research evaluates a cooled wheel cleaning jet (CWCJ) under different temperatures, applied simultaneously to MQL in the cylindrical grinding of AISI 4340 quenched and tempered steel, using a CBN wheel. For comparison, tests with the MQL, MQL + WCJ, and conventional techniques were also performed. Surface roughness, microhardness, and roundness deviation of the workpieces, wheel wear, and grinding power were the assessed output parameters. The machined workpieces were evaluated by optical, confocal, and scanning electron microscopies. The MQL + WCJ outperformed MQL and MQL + WCJ in all the tested conditions. The application of the cooled wheel cleaning jet reduced by up to 79% the surface roughness, 82% the wheel wear, 76% the roundness deviation, and 37% the grinding power, regarding MQL and MQL + WCJ techniques, contributing towards a sustainable and high-quality grinding process.

Similar content being viewed by others

References

Lee J, Lapira E, Bagheri B, Kao H-a (2013) Recent advances and trends in predictive manufacturing systems in big data environment. Manuf Lett 1:38–41. https://doi.org/10.1016/j.mfglet.2013.09.005

Ahuett-Garza H, Kurfess T (2018) A brief discussion on the trends of habilitating technologies for Industry 4.0 and smart manufacturing. Manuf Lett 15:60–63. https://doi.org/10.1016/j.mfglet.2018.02.011

Lee J, Davari H, Singh J, Pandhare V (2018) Industrial artificial intelligence for industry 4.0-based manufacturing systems. Manuf Lett 18:20–23. https://doi.org/10.1016/j.mfglet.2018.09.002

Ardestani MM, Chen Z, Wang L, Lian Q, Liu Y, He J, Li D, Jin Z (2014) Feed forward artificial neural network to predict contact force at medial knee joint: application to gait modification. Neurocomputing 139:114–129. https://doi.org/10.1016/J.NEUCOM.2014.02.054

Lee J, Bagheri B, Kao HA (2015) A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf Lett 3:18–23. https://doi.org/10.1016/j.mfglet.2014.12.001

Lee J, Bagheri B, Jin C (2016) Introduction to cyber manufacturing. Manuf Lett 8:11–15. https://doi.org/10.1016/j.mfglet.2016.05.002

Trent EM, Wright PK (2000) Metal cutting, 4th edn. Butterworth-Heinemann

Shaw MC, Cookson JO (2005) Metal cutting principles. Oxford university press, New York

Benedicto E, Carou D, Rubio EM (2017) Technical, economic and environmental review of the lubrication/cooling systems used in machining processes. Procedia Eng 184:99–116. https://doi.org/10.1016/j.proeng.2017.04.075

Irani RA, Bauer RJ, Warkentin A (2005) A review of cutting fluid application in the grinding process. Int J Mach Tools Manuf 45:1696–1705. https://doi.org/10.1016/j.ijmachtools.2005.03.006

Debnath S, Reddy MM, Yi QS (2014) Environmental friendly cutting fluids and cooling techniques in machining: a review. J Clean Prod 83:33–47. https://doi.org/10.1016/j.jclepro.2014.07.071

Garcia MV, Lopes JC, Diniz AE, Rodrigues AR, Volpato RS, Sanchez LEA, de Mello HJ, Aguiar PR, Bianchi EC (2020) Grinding performance of bearing steel using MQL under different dilutions and wheel cleaning for green manufacture. J Clean Prod:120376. https://doi.org/10.1016/j.jclepro.2020.120376

Bennett EO (1983) Water based cutting fluids and human health. Tribol Int 16:133–136. https://doi.org/10.1016/0301-679X(83)90055-5

Byrne G, Scholta E (1993) Environmentally clean machining processes - a strategic approach. CIRP Ann Manuf Technol 42:471–474. https://doi.org/10.1016/S0007-8506(07)62488-3

Klocke F, Eisenblatter G (1997) Dry cutting. Keynote Pap 46:519–526. https://doi.org/10.1016/S0007-8506(07)60877-4

Said Z, Gupta M, Hegab H, Arora N, Khan AM, Jamil M, Bellos E (2019) A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int J Adv Manuf Technol 105:2057–2086. https://doi.org/10.1007/s00170-019-04382-x

Liew PJ, Shaaroni A, Sidik NAC, Yan J (2017) An overview of current status of cutting fluids and cooling techniques of turning hard steel. Int J Heat Mass Transf 114:380–394. https://doi.org/10.1016/j.ijheatmasstransfer.2017.06.077

Sharif MN, Pervaiz S, Deiab I (2017) Potential of alternative lubrication strategies for metal cutting processes: a review. Int J Adv Manuf Technol 89:2447–2479

Goindi GS, Sarkar P (2017) Dry machining: a step towards sustainable machining – challenges and future directions. J Clean Prod 165:1557–1571. https://doi.org/10.1016/j.jclepro.2017.07.235

Dogra M, Sharma VS, Dureja JS, Gill SS (2018) Environment-friendly technological advancements to enhance the sustainability in surface grinding- a review. J Clean Prod 197:218–231. https://doi.org/10.1016/j.jclepro.2018.05.280

Sen B, Mia M, Krolczyk GM, Mandal UK, Mondal SP (2019) Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: a review on the perception of sustainable manufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology 1–32

Wang Y, Li C, Zhang Y, Yang M, Zhang X, Zhang N, Dai J (2017) Experimental evaluation on tribological performance of the wheel/workpiece interface in minimum quantity lubrication grinding with different concentrations of Al2O3 nanofluids. J Clean Prod 142:3571–3583. https://doi.org/10.1016/j.jclepro.2016.10.110

Silva LR, Corrêa ECS, Brandão JR, de Ávila RF (2020) Environmentally friendly manufacturing: behavior analysis of minimum quantity of lubricant - MQL in grinding process. J Clean Prod 256:103287. https://doi.org/10.1016/j.jclepro.2013.01.033

Barczak LM, Batako ADL, Morgan MN (2010) A study of plane surface grinding under minimum quantity lubrication (MQL) conditions. Int J Mach Tools Manuf 50:977–985. https://doi.org/10.1016/j.ijmachtools.2010.07.005

Shao Y, Fergani O, Ding Z, Li B, Liang SY (2015) Experimental investigation of residual stress in minimum quantity lubrication grinding of AISI 1018 steel. J Manuf Sci Eng 138:011009. https://doi.org/10.1115/1.4029956

de Martini FL, Lopes JC, Ribeiro FSF et al (2019) Thermal model for surface grinding application. Int J Adv Manuf Technol 104:2783–2793. https://doi.org/10.1007/s00170-019-04101-6

Hadad MJ, Tawakoli T, Sadeghi MH, Sadeghi B (2012) Temperature and energy partition in minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 54–55:10–17. https://doi.org/10.1016/j.ijmachtools.2011.11.010

Sato BK, Lopes JC, Diniz AE, Rodrigues AR, de Mello HJ, Sanchez LEA, Aguiar PR, Bianchi EC (2020) Toward sustainable grinding using minimum quantity lubrication technique with diluted oil and simultaneous wheel cleaning. Tribol Int 147:106276. https://doi.org/10.1016/j.triboint.2020.106276

Rodriguez RL, Lopes JC, Hildebrandt RA, Perez RRV, Diniz AE, de Ângelo Sanchez LE, Rodrigues AR, de Mello HJ, de Aguiar PR, Bianchi EC (2019) Evaluation of grinding process using simultaneously MQL technique and cleaning jet on grinding wheel surface. J Mater Process Technol 271:357–367. https://doi.org/10.1016/j.jmatprotec.2019.03.019

Lopes JC, Ventura CEH, de Fernandes LM et al (2019) Application of a wheel cleaning system during grinding of alumina with minimum quantity lubrication. Int J Adv Manuf Technol 102:333–341. https://doi.org/10.1007/s00170-018-3174-4

Bianchi EC, Rodriguez RL, Hildebrandt RA, Lopes JC, de Mello HJ, da Silva RB, de Aguiar PR (2018) Plunge cylindrical grinding with the minimum quantity lubrication coolant technique assisted with wheel cleaning system. Int J Adv Manuf Technol 95:2907–2916. https://doi.org/10.1007/s00170-017-1396-5

Ribeiro FSF, Lopes JC, Garcia MV et al (2020) Grinding performance by applying MQL technique: an approach of the wheel cleaning jet compared with wheel cleaning Teflon and alumina block. Int J Adv Manuf Technol:1–12. https://doi.org/10.1007/s00170-020-05334-6

Lopes JC, Garcia MV, Valentim M, Javaroni RL, Ribeiro FSF, de Angelo Sanchez LE, de Mello HJ, Aguiar PR, Bianchi EC (2019) Grinding performance using variants of the MQL technique: MQL with cooled air and MQL simultaneous to the wheel cleaning jet. Int J Adv Manuf Technol 105:4429–4442. https://doi.org/10.1007/s00170-019-04574-5

Lopes JC, Fragoso KM, Garcia MV, Ribeiro FSF, Francelin AP, de Angelo Sanchez LE, Rodrigues AR, de Mello HJ, Aguiar PR, Bianchi EC (2019) Behavior of hardened steel grinding using MQL under cold air and MQL CBN wheel cleaning. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-04571-8

Nguyen T, Zhang LC (2003) An assessment of the applicability of cold air and oil mist in surface grinding. J Mater Process Technol 140:224–230. https://doi.org/10.1016/S0924-0136(03)00714-3

Saberi A, Rahimi AR, Parsa H, Ashrafijou M, Rabiei F (2016) Improvement of surface grinding process performance of CK45 soft steel by minimum quantity lubrication (MQL) technique using compressed cold air jet from vortex tube. J Clean Prod 131:728–738. https://doi.org/10.1016/j.jclepro.2016.04.104

de Moraes DL, Garcia MV, Lopes JC, Ribeiro FSF, de Angelo Sanchez LE, Foschini CR, de Mello HJ, Aguiar PR, Bianchi EC (2019) Performance of SAE 52100 steel grinding using MQL technique with pure and diluted oil. Int J Adv Manuf Technol 105:4211–4223. https://doi.org/10.1007/s00170-019-04582-5

Stachurski W, Sawicki J, Wójcik R, Nadolny K (2018) Influence of application of hybrid MQL-CCA method of applying coolant during hob cutter sharpening on cutting blade surface condition. J Clean Prod 171:892–910. https://doi.org/10.1016/j.jclepro.2017.10.059

Mia M, Gupta MK, Lozano JA, Carou D, Pimenov DY, Królczyk G, Khan AM, Dhar NR (2019) Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. J Clean Prod 210:121–133. https://doi.org/10.1016/j.jclepro.2018.10.334

Maruda RW, Krolczyk GM, Wojciechowski S, Zak K, Habrat W, Nieslony P (2018) Effects of extreme pressure and anti-wear additives on surface topography and tool wear during MQCL turning of AISI 1045 steel. J Mech Sci Technol 32:1585–1591. https://doi.org/10.1007/s12206-018-0313-7

Tawakoli T, Hadad MJ, Sadeghi MH (2010) Influence of oil mist parameters on minimum quantity lubrication – MQL grinding process. Int J Mach Tools Manuf 50:521–531. https://doi.org/10.1016/j.ijmachtools.2010.03.005

Oliveira DDJ, Guermandi LG, Bianchi EC et al (2012) Improving minimum quantity lubrication in CBN grinding using compressed air wheel cleaning. J Mater Process Technol 212:2559–2568. https://doi.org/10.1016/j.jmatprotec.2012.05.019

Xue Y, Arjomandi M, Kelso R (2013) The working principle of a vortex tube. Int J Refrig 36:1730–1740. https://doi.org/10.1016/j.ijrefrig.2013.04.016

ASTM E384–17 (2017) Standard test method for microindentation hardness of materials. ASTM International, West Conshohocken

Malkin S, Guo C (2008) Grinding technology: theory and applications of machining with abrasives, 2nd edn. Industrial Press Inc, New York

Oliveira JFG, Silva EJ, Guo C, Hashimoto F (2009) Industrial challenges in grinding. CIRP Ann - Manuf Technol 58:663–680. https://doi.org/10.1016/j.cirp.2009.09.006

Beretta S, Romano S (2017) A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes. Int J Fatigue 94:178–191. https://doi.org/10.1016/j.ijfatigue.2016.06.020

Novovic D, Dewes RC, Aspinwall DK, Voice W, Bowen P (2004) The effect of machined topography and integrity on fatigue life. Int J Mach Tools Manuf 44:125–134. https://doi.org/10.1016/j.ijmachtools.2003.10.018

Hecker RL, Liang SY (2003) Predictive modeling of surface roughness in grinding. Int J Mach Tools Manuf 43:755–761. https://doi.org/10.1016/S0890-6955(03)00055-5

Puerto P, Fernández R, Madariaga J, Arana J, Gallego I (2013) Evolution of surface roughness in grinding and its relationship with the dressing parameters and the radial wear. Procedia Eng 63:174–182. https://doi.org/10.1016/j.proeng.2013.08.181

Javaroni RL, Lopes JC, Garcia MV, Ribeiro FSF, de Angelo Sanchez LE, de Mello HJ, Aguiar PR, Bianchi EC (2020) Grinding hardened steel using MQL associated with cleaning system and cBN wheel. Int J Adv Manuf Technol 107:2065–2080. https://doi.org/10.1007/s00170-020-05169-1

Zhu Y, Ding W, Rao Z, Fu Y (2019) Effect of grinding wheel speed on self-sharpening ability of PCBN grain during grinding of nickel-based superalloys with a constant undeformed chip thickness. Wear 426–427:1573–1583. https://doi.org/10.1016/j.wear.2018.12.064

Tawakoli T, Westkämper E, Rabiey M, Rasifard A (2007) Influence of the type of coolant lubricant in grinding with CBN tools. Int J Mach Tools Manuf 47:734–739. https://doi.org/10.1016/j.ijmachtools.2006.09.010

Agarwal S (2019) On the mechanism and mechanics of wheel loading in grinding. J Manuf Process 41:36–47. https://doi.org/10.1016/j.jmapro.2019.03.009

Shokrani A, Dhokia V, Newman ST (2012) Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int J Mach Tools Manuf 57:83–101. https://doi.org/10.1016/j.ijmachtools.2012.02.002

Cho N, Tu J (2001) Roundness modeling of machined parts for tolerance analysis. Precis Eng 25:35–47. https://doi.org/10.1016/S0141-6359(00)00053-2

Kwak JS (2005) Application of Taguchi and response surface methodologies for geometric error in surface grinding process. Int J Mach Tools Manuf 45:327–334. https://doi.org/10.1016/j.ijmachtools.2004.08.007

Hadad M, Sadeghi B (2012) Thermal analysis of minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 63:1–15. https://doi.org/10.1016/j.ijmachtools.2012.07.003

Batista da Silva R, Ferreira FI, Baptista FG, de Aguiar PR, de Souza Ruzzi R, Hubner HB, da Penha Cindra Fonseca M, Bianchi EC (2018) Electromechanical impedance (EMI) technique as alternative to monitor workpiece surface damages after the grinding operation. Int J Adv Manuf Technol 98:2429–2438. https://doi.org/10.1007/s00170-018-2390-2

Singh V, Venkateswara Rao P, Ghosh S (2012) Development of specific grinding energy model. Int J Mach Tools Manuf 60:1–13. https://doi.org/10.1016/j.ijmachtools.2011.11.003

Javaroni RL, Lopes JC, Diniz AE, Garcia MV, Ribeiro FSF, Tavares AB, Talon AG, Sanchez LEA, Mello HJ, Aguiar PR, Bianchi EC (2020) Improvement in the grinding process using the MQL technique with cooled wheel cleaning jet. Tribol Int 152:106512. https://doi.org/10.1016/j.triboint.2020.106512

Acknowledgments

The authors thank companies Norton Abrasives (Saint Gobain Group), ITW Chemical Products, and Emuge-Franken for the donations of the grinding wheel, the cutting fluids, and the vortex tube, respectively.

Funding

This work was supported by the São Paulo Research Foundation (FAPESP) (grant number 2018/22661-2), the Coordination for the Improvement of Higher Level Education Personnel (CAPES), and the National Council for Scientific and Technological Development (CNPq).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Javaroni, R.L., Lopes, J.C., Ribeiro, F.S.F. et al. Evaluation of a cooled wheel cleaning jet in minimum quantity lubrication grinding process. Int J Adv Manuf Technol 111, 1303–1317 (2020). https://doi.org/10.1007/s00170-020-06198-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06198-6