Abstract

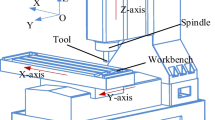

Three-axis structures are widely used as the main body of multi-axis CNC machine tools and coordinate measuring machines. As an open-loop mechanism, the cumulative effects of position-dependent/position-independent geometric errors of the moving axes cause significant volumetric deviation of the functional point. Such effect is more tangible for angular error motions, where they can considerably be magnified by long Abbe offsets. An appropriate volumetric error modeling approach should estimate the total effect of individual error motions accurately. Accuracy of the model depends on applied error propagation scheme and correctness of the error identification procedure. In this paper, both issues are investigated in order to enhance the practical validity of the model in presence of rigid-body and steady thermal assumptions. Regarding mechanical design of the sliding system, the linear axes are categorized in two different extruding type and sliding type with different error-mapping functions. Based on the homogeneous transformation matrix method, the overall consequence of error motions of each axis is calculated separately within entire working volume. The new approach explicitly contributes the axis design and structural configuration in error propagation procedure and facilitates the root cause identification for volumetric deviations of the functional point. The modeling scheme is verified experimentally on a three-axis CNC machine tool via comparison of the estimations with measured error values on circular and diagonal tool paths.

Similar content being viewed by others

References

(2012) ISO 230-1:2012 - Test code for machine tools -- Part 1: Geometric accuracy of machines operating under no-load or quasi-static conditions

Ibaraki S, Knapp W (2012) Indirect measurement of volumetric accuracy for three-axis and five-axis machine tools: a review. Int J Autom Technol 6:110–124. https://doi.org/10.3929/ethz-a-007593181

Murray RM, Li Z, Sastry SS (1994) A mathematical introduction to robotic manipulation book. doi: 10.1.1.169.3957

Tsai L-W (1999) Robot analysis: the mechanics of serial and parallel manipulators. Wiley

Yang J, Altintas Y (2013) Generalized kinematics of five-axis serial machines with non-singular tool path generation. Int J Mach Tools Manuf 75:119–132. https://doi.org/10.1016/j.ijmachtools.2013.09.002

Donmez MA, Blomquist DS, Hocken RJ et al (1986) A general methodology for machine tool accuracy enhancement by error compensation. Precis Eng 8:187–196. https://doi.org/10.1016/0141-6359(86)90059-0

Kiridena VSB, Ferreira PM (1994) Kinematic modelling of quasistatic errors of three-axis machining centers. Int J mach Tools Manufact 34:85–100

López De Lacalle LN, Lamikiz A, Ocerin O et al (2008) The Denavit and Hartenberg approach applied to evaluate the consequences in the tool tip position of geometrical errors in five-axis milling centres. Int J Adv Manuf Technol 37:122–139. https://doi.org/10.1007/s00170-007-0956-5

Vahebi Nojedeh M, Habibi M, Arezoo B (2011) Tool path accuracy enhancement through geometrical error compensation. Int J Mach Tools Manuf 51:471–482. https://doi.org/10.1016/j.ijmachtools.2011.02.005

Tian W, Gao W, Zhang D, Huang T (2014) A general approach for error modeling of machine tools. Int J Mach Tools Manuf 79:17–23. https://doi.org/10.1016/j.ijmachtools.2014.01.003

Xiang S, Altintas Y (2016) Modeling and compensation of volumetric errors for five-axis machine tools. Int J Mach Tools Manuf 101:65–78. https://doi.org/10.1016/j.ijmachtools.2015.11.006

Habibi M, Arezoo B, Vahebi Nojedeh M (2011) Tool deflection and geometrical error compensation by tool path modification. Int J Mach Tools Manuf 51:471–482. https://doi.org/10.1016/j.ijmachtools.2011.02.005

Schwenke H, Knapp W, Haitjema H et al (2008) Geometric error measurement and compensation of machines—an update. CIRP Ann - Manuf Technol 57:660–675. https://doi.org/10.1016/j.cirp.2008.09.008

Huang N, Jin Y, Bi Q, Wang Y (2015) Integrated post-processor for 5-axis machine tools with geometric errors compensation. Int J Mach Tools Manuf 94:65–73. https://doi.org/10.1016/j.ijmachtools.2015.04.005

Soori M, Arezoo B, Habibi M (2013) Dimensional and geometrical errors of three-axis CNC milling machines in a virtual machining system. Comput Des 45:1306–1313. https://doi.org/10.1016/j.cad.2013.06.002

Pezeshki M, Arezoo B (2016) Kinematic errors identification of three-axis machine tools based on machined work pieces. Precis Eng 43:493–504. https://doi.org/10.1016/j.precisioneng.2015.09.018

Vahebi Nojedeh M, Arezoo B (2016) Functional accuracy investigation of work-holding rotary axes in five-axis CNC machine tools. Int J Mach Tools Manuf 111:17–30. https://doi.org/10.1016/j.ijmachtools.2016.09.002

Chen G, Liang Y, Sun Y et al (2013) Volumetric error modeling and sensitivity analysis for designing a five-axis ultra-precision machine tool. Int J Adv Manuf Technol 68:2525–2534. https://doi.org/10.1007/s00170-013-4874-4

Liu X, Zhang X, Fang F, Liu S (2016) Identification and compensation of main machining errors on surface form accuracy in ultra-precision diamond turning. Int J Mach Tools Manuf 105:45–57. https://doi.org/10.1016/j.ijmachtools.2016.03.001

Ekinci TO, Mayer JRR (2007) Relationships between straightness and angular kinematic errors in machines. Int J Mach Tools Manuf 47:1997–2004. https://doi.org/10.1016/j.ijmachtools.2007.02.002

Majda P (2012) Modeling of geometric errors of linear guideway and their influence on joint kinematic error in machine tools. Precis Eng 36:369–378. https://doi.org/10.1016/j.precisioneng.2012.02.001

Díaz-Tena E, Ugalde U, López De Lacalle LN et al (2013) Propagation of assembly errors in multitasking machines by the homogenous matrix method. Int J Adv Manuf Technol 68:149–164. https://doi.org/10.1007/s00170-012-4715-x

Liu Y, Gao D, Lu Y (2014) Volumetric calibration in multi-space in large-volume machine based on measurement uncertainty analysis. Int J Adv Manuf Technol 76:1493–1503. https://doi.org/10.1007/s00170-014-6367-5

Zhong G, Wang C, Yang S et al (2015) Position geometric error modeling, identification and compensation for large 5-axis machining center prototype. Int J Mach Tools Manuf 89:142–150. https://doi.org/10.1016/j.ijmachtools.2014.10.009

Li J, Xie F, Liu XJ (2016) Geometric error modeling and sensitivity analysis of a five-axis machine tool. Int J Adv Manuf Technol 82:2037–2051. https://doi.org/10.1007/s00170-015-7492-5

Chen JX, Lin SW, Zhou XL (2016) A comprehensive error analysis method for the geometric error of multi-axis machine tool. Int J Mach Tools Manuf 106:56–66. https://doi.org/10.1016/j.ijmachtools.2016.04.001

Fu G, Fu J, Gao H, Yao X (2017) Squareness error modeling for multi-axis machine tools via synthesizing the motion of the axes. Int J Adv Manuf Technol 89:2993–3008. https://doi.org/10.1007/s00170-016-9259-z

He G, Sun G, Zhang H, et al (2017) Hierarchical error model to estimate motion error of linear motion bearing table. Int J Adv Manuf Technol 93:1915–1927. https://doi.org/10.1007/s00170-017-0635-0

Lee K Il, Yang SH (2016) Compensation of position-independent and position-dependent geometric errors in the rotary axes of five-axis machine tools with a tilting rotary table. Int J Adv Manuf Technol 85:1677–1685. https://doi.org/10.1007/s00170-015-8080-4

Leach R (2014) Abbe error/offset. In: CIRP Encycl. Prod. Eng. Springer Berlin Heidelberg, Berlin, Heidelberg, pp 1–4

Lin Y, Shen Y (2003) Modelling of five-axis machine tool metrology models using the matrix summation approach. Int J Adv Manuf Technol 21:243–248. https://doi.org/10.1007/s001700300028

(2001) ISO 841:2001: Industrial automation systems and integration-numerical control of machines-coordinate system and motion nomenclature. http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=23949. Accessed 14 Jan 2016

Gomes AJP, Voiculescu I, Jorge J, et al (2009) Implicit curves and surfaces: mathematics, Data Structures and Algorithms. Springer

ISO 230-2:2014- Test code for machine tools -- Part 2: Determination of accuracy and repeatability of positioning of numerically controlled axes. http://www.iso.org/iso/catalogue_detail.htm?csnumber=55295. Accessed 26 Dec 2016

ISO 230-6:2002- Test code for machine tools -- Part 6: Determination of positioning accuracy on body and face diagonals (Diagonal displacement tests)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vahebi, M., Arezoo, B. Accuracy improvement of volumetric error modeling in CNC machine tools. Int J Adv Manuf Technol 95, 2243–2257 (2018). https://doi.org/10.1007/s00170-017-1294-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1294-x