Abstract

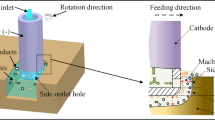

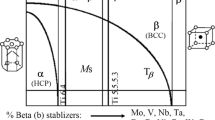

Plunge milling is an efficient machining process for roughing deep pockets. Its efficiency is mainly due to low radial forces on the cutter. This leads to reduced bendings and vibrations that allow one to improve cutting parameter values. The machining time can then be reduced with respect to machining processes with constant Z-level. Recently, another machining process has been introduced, called ”balancing of the transversal cutting force” (BotTCF), that is also characterized by a suitable distribution of forces on the cutter. It has been applied only to finishing operations on complex surfaces. In this paper, we present two main contributions. First, we extend the BotTCF concept to roughing open deep pockets and semi-open pockets opened from side to side. This is mainly based on successive parallel ramping trajectories, defined by an optimal angle which ensures a good balancing of the transversal cutting forces. This can be applied to 3-axis and 5-axis computer numerical control (CNC) machine tools. Second, we propose a new, hybrid methodology for roughing semi-open pockets (not opened from side to side) and closed pockets. It is based on the combination of ramping trajectories with BotTCF and plunge milling. The proposed methodology is developed for three-axis machining and can be extended to five-axis machining. Based on an identical criterion (identical maximum force acting on the cutters), we perform a fair machining-time comparison of plunge milling with the proposed hybrid method applied on a closed deep pocket: a simplified aeronautical housing made of magnesium-rare earth alloy. Results show a significant gain in machining time when the hybrid method is applied.

Similar content being viewed by others

References

Rauch M, Hascoet J-Y (2012) Selecting a milling strategy with regard to the machine tool capabilities: application to plunge milling. Int J Adv Manuf Technol 59(1–4):47–54

Cafieri S, Monies F, Mongeau M, Bes C (2016) Plunge milling time optimization via mixed-integer nonlinear programming. Comput Ind Eng 98:434–445

Ko JH, Altintas Y (2006) Dynamics and stability of plunge milling operations. J Manuf Sci Eng 129(1):32–40

Ko JH, Altintas Y (2007) Time domain model of plunge milling operation. Int J Mach Tools Manuf 47(9):1351–1361

Altintas Y, Ko JH (2006) Chatter stability of plunge milling. CIRP Ann Manuf Technol 55(1):361–364

Danis I, Wojtowicz N, Monies F, Lamesle P, Lagarrigue P (2013) Cutting conditions and surface integrity during dry plunge-milling of a wrought magnesium alloy. Procedia Engineering 63:36–44

Danis I, Wojtowicz N, Monies F, Lagarrigue P (2014) Influence of dry plunge milling conditions on surface integrity of magnesium alloys. International Journal of Mechatronics and Manufacturing Systems 7(2–3):141–156

Danis I, Monies F, Lagarrigue P, Wojtowicz N (2016) Cutting forces and their modelling in plunge milling of magnesium-rare earth alloys. Int J Adv Manuf Technol 84(9):1801–1820

Gilles P, Cohen G, Monies F, Rubio W (2012) Torus cutter positioning in five-axis milling using balance of the transversal cutting force. Int J Adv Manuf Technol 66(5–8):965–973

Gilles P, Cohen G, Monies F, Rubio W (2014) Machining strategy in five-axis milling using balance of the transversal cutting force. Int J Adv Manuf Technol 72(9–12):1377–1387

Gilles P, Monies F, Rubio W (2007) Optimum orientation of a torus milling cutter: method to balance the transversal cutting force. Int J Mach Tools Manuf 47(15):2263–2272

Gilles P, Cohen G, Monies F, Rubio W (2008) Dynamic behaviour improvement for a torus milling cutter using balance of the transversal cutting force. Int J Adv Manuf Technol 40(7–8):669–675

Moussaoui K, Monies F, Mousseigne M, Gilles P, Rubio W (2015) Balancing the transverse cutting force during inclined milling and effect on tool wear: application to Ti6al4v. Int J Adv Manuf Technol 1–22

Monies F, Danis I, Lagarrigue P, Gilles P, Rubio W (2017) Balancing of the transversal cutting force for pocket milling cutters: application for roughing a magnesium-rare earth alloy. Int J Adv Manuf Technol 89(1):45–64

Sandvik (2012) Plunge milling - how to apply. http://www.sandvik.coromant.com/en-gb/knowledge/milling/application_overview/holes_and_cavities/plunge_milling/Pages/default.aspx

Sun C, Bi Q, Wang Y, Huang N (2014) Improving cutter life and cutting efficiency of five-axis plunge milling by simulation and tool path regeneration. Int J Adv Manuf Technol 77(5–8):965–972

Sun T, Fu Y-c, He L, Chen X-m, Zhang W-g, Chen W, Su X-b (2016) Machinability of plunge milling for damage-tolerant titanium alloy TC21. Int J Adv Manuf Technol 85(5–8):1315–1323

Acknowledgments

The authors would like to thank the CARAIBE project, which is supported by french national funds (FUI) and the Aerospace Valley cluster.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monies, F., Danis, I., Bes, C. et al. A new machining strategy for roughing deep pockets of magnesium-rare earth alloys. Int J Adv Manuf Technol 92, 3883–3901 (2017). https://doi.org/10.1007/s00170-017-0444-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0444-5