Abstract

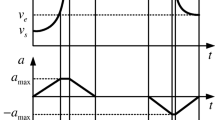

The ability of drive unit limits the velocity, acceleration, and jerk of the axis, and the process and tool path geometry constrain the feedrate, acceleration, and jerk of the trajectory. It is of great difficulty and importance to schedule a suitable feedrate profile to achieve the higher machining efficiency and satisfy all the constraints. Due to the complexity of the feedrate scheduling algorithm, this paper presents an offline predictive feedrate scheduling method considering the constraints of trajectory system and drive system. The constraints in the drive system are transformed to the trajectory system appropriately, which reduces the difficulty of feedrate scheduling. The one-dimensional high-order time-optimal problem is solved by a numerical calculation method according to the bang-bang control method. The predictive method is applied to find the switching points of the jerk. Then a time-optimal feedrate profile under all the constraints is obtained. Both simulations and experiments are carried out to prove the effectiveness of the proposed offline predictive feedrate scheduling method.

Similar content being viewed by others

References

Beudaert X, Pechard P-Y, Tournier C (2011) 5-Axis tool path smoothing based on drive constraints. Int J Mach Tools Manuf 51(12):958–965. doi:10.1016/j.ijmachtools.2011.08.014

Zhang LB, You YP, He J, Yang XF (2010) The transition algorithm based on parametric spline curve for high-speed machining of continuous short line segments. Int J Adv Manuf Technol 52(1–4):245–254. doi:10.1007/s00170-010-2718-z

Ernesto CA, Farouki RT (2011) High-speed cornering by CNC machines under prescribed bounds on axis accelerations and toolpath contour error. Int J Adv Manuf Technol 58(1–4):327–338. doi:10.1007/s00170-011-3394-3

Altintas Y, Erkorkmaz K, Zhu WH (2000) Sliding mode controller design for high speed feed drives. CIRP Ann Manuf Technol 49(1):265–270. doi:10.1016/s0007-8506(07)62943-6

Pritschow G, Croon N (2013) Ball screw drives with enhanced bandwidth by modification of the axial bearing. CIRP Ann Manuf Technol 62(1):383–386. doi:10.1016/j.cirp.2013.03.086

Varanasi KK, Nayfeh SA (2004) The dynamics of lead-screw drives: low-order modeling and experiments. J Dyn Syst Meas Control 126(2):388–396

Bobrow JE, Dubowsky S, Gibson J (1985) Time-optimal control of robotic manipulators along specified paths. Int J Robot Res 4:3–17

Shin K, McKay N (1985) Minimum-time control of robotic manipulators with geometric path constraints. IEEE Trans Autom Control 30:531–541

Dong J, Stori JA (2006) A generalized time-optimal bidirectional scan algorithm for constrained feed-rate optimization. J Dyn Syst Meas Control 128(2):379. doi:10.1115/1.2194078

Shin KG, McKay ND (1986) A dynamic programming approach to trajectory planning of robotic manipulators. IEEE Trans Autom Control 131(6):491–500

Gourdeau R, Schwartz HM (1989) Optimal control of a robot manipulator using a weighted time-energy cost function. Decision and Control, 1989. Proceedings of the 28th IEEE Conference on. IEEE, 1628–1631

Lai J-Y, Lin K-Y, Tseng S-J, Ueng W-D (2007) On the development of a parametric interpolator with confined chord error, feedrate, acceleration and jerk. Int J Adv Manuf Technol 37(1–2):104–121. doi:10.1007/s00170-007-0954-7

Fan W, Gao X-S, Yan W, Yuan C-M (2012) Interpolation of parametric CNC machining path under confined jounce. Int J Adv Manuf Technol 62(5–8):719–739. doi:10.1007/s00170-011-3842-0

Dong J, Ferreira PM, Stori JA (2007) Feed-rate optimization with jerk constraints for generating minimum-time trajectories. Int J Mach Tools Manuf 47(12–13):1941–1955. doi:10.1016/j.ijmachtools.2007.03.006

Zhang K, Yuan C-M, Gao X-S (2012) Efficient algorithm for time-optimal feedrate planning and smoothing with confined chord error and acceleration. Int J Adv Manuf Technol 66(9–12):1685–1697. doi:10.1007/s00170-012-4450-3

Zhang K, Yuan C-M, Gao X-S, Li H (2012) A greedy algorithm for feedrate planning of CNC machines along curved tool paths with confined jerk. Robot Comput Integr Manuf 28(4):472–483. doi:10.1016/j.rcim.2012.02.006

Altintas Y, Erkorkmaz K (2003) Feedrate optimization for spline interpolation in high speed machine tools. CIRP Ann Manuf Technol 52(1):297–302. doi:10.1016/s0007-8506(07)60588-5

Sencer B, Altintas Y, Croft E (2008) Feed optimization for five-axis CNC machine tools with drive constraints. Int J Mach Tools Manuf 48(7–8):733–745. doi:10.1016/j.ijmachtools.2008.01.002

Zhang Q, Li S-R (2013) Efficient computation of smooth minimum time trajectory for CNC machining. Int J Adv Manuf Technol 68(1–4):683–692. doi:10.1007/s00170-013-4790-7

Fan W, Gao X-S, Lee C-H, Zhang K, Zhang Q (2013) Time-optimal interpolation for five-axis CNC machining along parametric tool path based on linear programming. Int J Adv Manuf Technol 69(5–8):1373–1388. doi:10.1007/s00170-013-5083-x

Erkorkmaz K, Heng M (2008) A heuristic feedrate optimization strategy for NURBS toolpaths. CIRP Ann Manuf Technol 57(1):407–410. doi:10.1016/j.cirp.2008.03.039

Ridwan F, Xu X, Ho FCL (2012) Adaptive execution of an NC program with feed rate optimization. Int J Adv Manuf Technol 63(9–12):1117–1130. doi:10.1007/s00170-012-3959-9

Heng M, Erkorkmaz K (2010) Design of a NURBS interpolator with minimal feed fluctuation and continuous feed modulation capability. Int J Mach Tools Manuf 50(3):281–293. doi:10.1016/j.ijmachtools.2009.11.005

Lee A-C, Lin M-T, Pan Y-R, Lin W-Y (2011) The feedrate scheduling of NURBS interpolator for CNC machine tools. Comput Aided Des 43(6):612–628. doi:10.1016/j.cad.2011.02.014

Beudaert X, Lavernhe S, Tournier C (2012) Feedrate interpolation with axis jerk constraints on 5-axis NURBS and G1 tool path. Int J Mach Tools Manuf 57:73–82. doi:10.1016/j.ijmachtools.2012.02.005

Sun Y, Bao Y, Kang K, Guo D (2013) An adaptive feedrate scheduling method of dual NURBS curve interpolator for precision five-axis CNC machining. Int J Adv Manuf Technol 68(9–12):1977–1987. doi:10.1007/s00170-013-4816-1

Sun Y, Zhao Y, Bao Y, Guo D (2014) A novel adaptive-feedrate interpolation method for NURBS tool path with drive constraints. Int J Mach Tools Manuf 77:74–81. doi:10.1016/j.ijmachtools.2013.11.002

Bryson AE, Ho YC (1975) Applied optimal control: optimization, estimation and control. Wiley, New York

Erkorkmaz K, Layegh SE, Lazoglu I, Erdim H (2013) Feedrate optimization for freeform milling considering constraints from the feed drive system and process mechanics. CIRP Ann Manuf Technol 62(1):395–398. doi:10.1016/j.cirp.2013.03.084

Guo J-X, Zhang K, Zhang Q, Gao X-S (2013) Efficient time-optimal feedrate planning under dynamic constraints for a high-order CNC servo system. Comput Aided Des 45(12):1538–1546. doi:10.1016/j.cad.2013.07.002

Piegl L, Tiller W (1997) The NURBS book, 2nd edn. Springer, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, L., Zhang, L., Ji, S. et al. An offline predictive feedrate scheduling method for parametric interpolation considering the constraints in trajectory and drive systems. Int J Adv Manuf Technol 83, 2143–2157 (2016). https://doi.org/10.1007/s00170-015-8112-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8112-0