Abstract

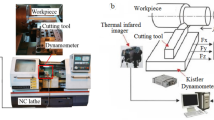

The main objective of this work is to investigate the tapping operation of cast iron when varying the cutting speed and the method of application of cutting fluid, monitoring tool wear, torque, and axial force during the operation. Two types of gray cast iron were evaluated: CrCuSn alloy, FC 250; CrCuSnMo alloy, FC 300, and compacted graphite iron machine tool, FV 350. Tests were performed at two lubrication/cooling conditions: in the first one, it was applied an emulsion of water and oil; in the second one, the fluid was applied in minimal quantity (MQF), at pressure of 6.0 bar and intermittent spray at a frequency of 1 pulse/s, resulting in a flow rate of 30 ml/h. For MQF condition, a vegetable oil was used. Torque, axial forces, and tool wear were measured during the operation. Statistical analysis showed that the cutting speed was the parameter that most influences the torque, followed by the cutting fluid and the material hardness.

Similar content being viewed by others

References

Carvalho AO, Brandão LC, Panzera TH, Lauro CH (2012) Analysis of form threads using fluteless taps in cast magnesium alloy (AM60). J Mater Process Technol 212:1753–1760

Pereira IC, Da Silva MB, Corrêa JG, Da Cunha DF (2012) Analysis of torque and axial force in tapping operations using different types of fluid application when machining alloyed Gray iron (CrCuSn and CrCuSnMo) and compacted graphite iron ISO 350. 9th International Conference of High Speed Machining. San Sebástian-Spain

Cao T, Sutherland JW (2002) Investigation of thread tapping load characteristics through mechanistic modeling and experimentation. Int J Mach Tools Manuf 42:1527–1538

Henderer T (2006) Solid synchronicity: realizing true high-speed synchronous tapping with solid-carbide tools. Cutt Tool Eng 58(2)

Ahn JH, Lee DJ, Kim HY, Cho KK (2003) Effects of synchronizing errors on cutting performance in the ultra-high-speed tapping. CIRP Ann Manuf Technol 52:53–56

Lorenz G (1980) Division of manufacturing technology. CSIRO 29:1–4

ASTM D5619-00 (2000) Standard test method for comparing metal removal fluids using the tapping torque test machine. American Society for Testing and Materials

Mezentsev OA, Zhu R, DeVor RE, Kapoor SG, Kline WA (2002) Use of radial forces for fault detection in tapping. Int J Mach Tools Manuf 42:479–488

Da Mota PR (2006) Investigation of the behaviour of high speed steel tools in tapping operation at high speed cutting, 140 p. Master dissertation, Federal University of Uberlandia, Uberlandia

Klocke F, Gerschwiler K (2003) Minimalmengenschmierung–Systeme, Medien, Einsatzbeispiele und ökonomische Aspekte der Trockenbearbeitung, Trockenbearbeitung von Metallen. Proc VDI Sem 18:2.1–2.20

Weinert K, Inasaki I, Sutherland JW, Wakabayashi T (2004) Dry machining and minimum quantity lubrication. CIRP Ann Manuf Tecnol 53:511–534

Naves VTG (2009) Stud of machinability of the alloyed gray cast iron (CrCuSn and CrCuSnMo) and compacted graphite iron ISO 350 in front milling in high speed machine. 145 f. Master in Mechanical Engineering, Federal University of Uberlândia, Uberlândia

Machado AR, Abrão AM, Coelho RT, Da Ssilva MB (2009) Theory of machining of materials, 1st edn. Blucher, São Paulo, 371 p

Guesser WL (2009) Mechanical properties of the cast iron, 1st edn. Blucher, São Paulo, 336 p

Box GE, Wilson KB (1951) On the experimental attainment of optimum condition. J Roy Stat Soc B 13

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pereira, I.C., Da Silva, M.B., Da Cunha, D.F. et al. Analysis of tapping process in three types of cast iron. Int J Adv Manuf Technol 82, 1041–1048 (2016). https://doi.org/10.1007/s00170-015-7430-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7430-6