Abstract

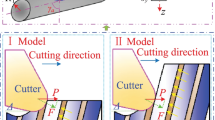

The use of carbon fiber reinforced polymer (CFRP) composites becomes more attractive today in various industrial sectors such as aerospace, naval, and automotive. This is due to their high mechanical properties (strength, stiffness, light weight, etc.) and corrosion resistance. Machining processes such as trimming or drilling are frequently used to achieve dimensional tolerance and assembly requirements. However, a damage process involving matrix cracking, fiber fracture, and interlaminar delamination often occurs when machining these materials. In the current work, a numerical analysis has been used to identify the most significant machining factors and their interaction on the induced damage and cutting force. The orthogonal Design of Experiments (DoE) L27(313) of Taguchi has been applied to investigate the effect of the fiber orientation, the tool rake angle, the depth of cut, and the tool edge radius. The induced damage can strongly affect the surface roughness (surface quality of the workpieces) and considerably limits the use of these materials in many industrial applications. First of all, a coupled elastoplastic damage behavior law was adopted to simulate the permanent deformations caused by plasticity and to predict the degradation of mechanical properties due to the initiation of damage and its progression inside the composite structure. Satisfactory numerical results have been found and a good correlation has been obtained compared to experimental trends. The results reveal that the interaction between some factors could be neglected and the obtained responses are greatly influenced by the fiber orientation and the depth of cut rather than the tool rake angle and the tool edge radius.

Similar content being viewed by others

References

Liu DF, Tang YJ, Cong WL (2012) A review of mechanical drilling for composite laminates. Compos Struct 94:1265–1279

Tsao CC, Hocheng H (2008) Evaluation of thrust force and surface roughness in drilling composite material using Taguchi analysis and neural network. J Mater Proc Technol 203(1–3):342–348

Vijayan K, Karthi P, Ramanathan A, Elanghovan M, Senthil Kumar M, Zitoune R, Davim JP (2012) Optimisation of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos Part B 43(4):1791–1799

Koplev A (1980) Cutting on CFRP with single edge tools. In: Proceedings of the Third International Conference on Composite Materials, Paris 2:1597–1605

Koplev A, Lystrup A, Vorm T (1983) The cutting process, chips and cutting forces in machining CFRP. Composites 14(4):371–376

Wang DH, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite part I: unidirectional laminate. Int J Mach Tool Manul 35(12):1623–1638

Bhatnagar N, Ramakrishnan N, Naik NK, Komanduri R (1995) On the machining of fiber reinforced plastic (FRP) composite laminates. Int J Mach Tool Manuf 35(5):701–716

Arola D, Ramulu M, Wang DH (1996) Chip formation in orthogonal trimming of graphite/epoxy. Compos Part A 27:121–133

Ugo EE, Sherif El-Gizawy A, Chukwujekwu Okafor A (2001) An approach for development of damage-free drilling of carbon fiber reinforced thermosets. Int J Mach Tool Manuf 41:1795–1814

Palanikumar K (2011) Experimental investigation and optimisation in drilling of GFRP composites. Measurement 44:2138–2148

Rajasekaran T, Palanikumar K, Arunachalam S (2013) Investigation on the turning parameters for surface roughness using Taguchi analysis. Procedia Engineering 51:781–790

J.S. Pang, M.N.M. Ansari, Omar S. Zaroog, Moaz H. Ali, S.M. Sapuan. Taguchi design optimization of machining parameters on the CNC end milling process of halloysite nanotube with aluminium reinforced epoxy matrix (HNT/Al/Ep) hybrid composite. HBRC Journal 2013

Arola D, Ramulu M (1997) Orthogonal cutting of fiber-reinforced composites: a finite element analysis. Int J Mach Tool Manuf 39(5):597–613

Ramesh MV, Seetharamu KN, Ganesan N, Sivakumar MS (1998) Analysis of machining of FRPs using FEM. Int J Mach Tools Manuf 38(12):1531–1549

Arola D, Sultan MB, Ramulu M (2002) Finite element modeling of edge trimming fiber-reinforced plastics. transaction of ASME J Eng Mater and Technol 124:32–41

Lasri L, Nouari M, El-Mansori M (2009) Modelling of chip separation in machining unidirectional FRP composites by stiffness degradation concept. Compos Sci Technol 69:684–692

ABAQUS Documentation for version 6.11-2 Dassault systems Simulia, 2011

Rao GVG, Mahajan P, Bhatnagar N (2007) Micro-mechanical modeling of machining of FRP composites. Cutting force analysis. Compos Sci Technol 67:579–593

Zitoune R, Collombet F, Lachaud F, Piquet R, Pasquet P (2005) Experimental calculation of the cutting conditions representative of the long fiber composite drilling Phase. Compos Sci Techno 65:455–466

Wang XM, Zhang LC (2003) An experimental investigation into the orthogonal cutting of unidirectional fibre reinforced plastics. Int J of Mach Tool Manuf 43:1015–1022

Jamal YCA. Machining of polymer composites. Springer 2009

Bhatnagar N, Nayak D, Singh I, Chouhan H, Mahajan P (2004) Determination of machining-induced damage characteristics of fiber reinforced plastic composite laminates. Mater Manuf Process 19(6):1009–1023

Mahdi M, Zhang L (2001) A finite element model for the orthogonal cutting of fiber reinforced composite materials. J Mater Process Technol 113(1–3):373–377

Nayak D, Bhatnagar N, Mahajan P (2005) Machining studies of UD-FRP composites part 2: finite element analysis. Machining Sci Technol 9:503–528

Lasri L. Modélisation macromécanique et micromécanique de l’usinage des composites à matrice polymère et fibres longues. PhD thesis; 2009

Lasri L, Nouari M, El-Mansori M (2011) Wear resistance and induced cutting damage of aeronautical FRP components obtained by machining. Wear 271(9–10):2542–2548

Iliescu D, Gehin D, Iordanoff I, Girot F, Gutiérrez ME (2010) A discrete element method for the simulation of CFRP cutting. Compos Sci Technol 70:73–80

Santiuste C, Soldani X, Miguélez HM (2010) Machining FEM model of long fiber composites for aeronautical components. Compos Struct 92:691–698

Soldani X, Santiuste C, Muñoz-Sánchez A, Miguélez H (2011) Influence of tool geometry and numerical parameters when modelling orthogonal cutting of LFRP composites. Compos Part A 42:1205–1216

Calzada KA, Kapoor SG, DeVor RE, Samuel J, Srivastava AK (2011) Modeling and interpretation of fiber orientation-based failure mechanisms in machining of carbon fiber-reinforced polymer composites. J Manuf Processes 14:141–149

Lemaitre J, Chaboche JL. Mechanics of solid materials. Cambridge University Press 1990; Cambridge, UK

Crisfield MA. Non-linear finite element analysis of solids and structures. Volume 1: essentials. Wiley 1991

Ladeveze P, LeDantec E (1992) Damage modelling of the elementary ply for laminated composites. Compos Sci Technol 43:257–267

Allix O, Feissel P, Thévenet P (2003) A delay damage mesomodel of laminates under dynamic loading basic aspects and identification issues. Comput Struct 81:1177–1191

Lubineau G, Ladevèze P (2008) Construction of a micromechanics-based intralaminar mesomodel, and illustrations in ABAQUS/Standard. Comput Mater Sci 43(1):137–145

Allix O, Deü JF (1997) Delay-damage modelling for fracture prediction of laminated composites under dynamic loading. Eng Trans 45:29–46

Ladevèze P, Allix O, Deü JF, Lévêque D (2000) A mesomodel for localisation and damage computation in laminates. Comput Meth Appl Mech Engrg 183:105–122

Feld, N. Vers un pont micro-méso de la rupture en compression des composites stratifiés. PhD thesis; pp 115, 2011

Schimmerling P, Sisson JC, Zaïdi A (1998) Pratique des plans d′expériences. Lavoisier, Paris

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zenia, S., Ben Ayed, L., Nouari, M. et al. Numerical analysis of the interaction between the cutting forces, induced cutting damage, and machining parameters of CFRP composites. Int J Adv Manuf Technol 78, 465–480 (2015). https://doi.org/10.1007/s00170-014-6600-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6600-2