Abstract

Water penetration length is one of the most important indexes of the water-assisted injection molding parts, the maximization of which is a particularly significant optimization objective. The effects of processing parameters, such as the short shot size, melt temperature, water pressure, and delay time, on water penetration length were exploited by using single factor experiment method and computational fluid dynamics analysis. In addition, the maximization of water penetration length on dimensional transition and curved-section parts by integrating the Taguchi orthogonal array design, radial basis function neural network, and particle swarm optimization was investigated. The research results showed that the two primary parameters affecting the water penetration length were the short shot size and water pressure, and that the effects of the melt temperature and delay time were little. Furthermore, the maximum water penetration length after optimization was slightly bigger than that of the confirmation experiment, which indicated that the optimization methodology was reliable and effective.

Similar content being viewed by others

References

Knights M (2002) Water injection molding makes hollow parts faster, lighter. Plast Tech 48(4):42–47, 62–63

Liu SJ, Wu YC, Lai PC (2005) Water penetration stability in water assisted injection molded symmetric rib. Int Polym Proc 4:352–359

Liu SJ, Lin SP (2006) Factors affecting the formation of fingering in water-assisted injection molded thermoplastics. Adv Polym Tech 25(2):98–108

Liu SJ, Wu YC, Chen WK (2006) Surface gloss difference on water assisted injection moulded thermoplastic parts: effects of processing variables. Plast Rubber Compos 35(1):29–36

Lin KY, Liu SJ (2010) Morphology of fluid assisted injection molded polycarbonate/polyethylene blends. Macromol Mater Eng 295:342–350

Sannen S, De Keyzer J, Van Puyvelde P (2011) The influence of melt and process parameters on the quality and occurrence of part defects in water-assisted injection molded tubes. Int Polym Proc 5:551–559

Ahmadzai A, Behravesh AH (2011) Effect of processing parameters on water penetration in water assisted injection molding of ABS. Polimery 56(3):232–239

Liu SJ, Chen YS (2004) The manufacturing of thermoplastic composite parts by water-assisted injection-molding technology. Compos Part A Appl S 35:171–180

Huang HX, Deng ZW (2008) Effects and optimization of processing parameters in water-assisted injection molding. J Appl Polym Sci 108:228–235

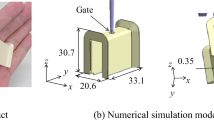

Yang JG, Zhou XH (2013) Numerical simulation on residual wall thickness of tubes with dimensional transitions and curved sections in water-assisted injection molding. J Appl Polym sci 128(3):1987–1994

Broomhead DS, Lowe D (1988) Multivariable functional interpolation and adaptive networks. Nonl Phen Compl Syst 2:321–355

Shie JR (2008) Optimization of injection molding process for contour distortions of polypropylene composite components by a radial basis neural network. Int J Adv Manuf Technol 36:1091–1103

Li C, Wang FL, Chang YQ, Liu Y (2010) A modified global optimization method based on surrogate model and its application in packing profile optimization of injection molding process. Int J Adv Manuf Technol 48:505–511

Srinivasa Pai P, Nagabhushana TN, Ramakrishna Rao PK (2002) Flank wear estimation in face milling based on radial basis function neural networks. Int J Adv Manuf Technol 20:241–247

Mollah AA, Pratihar DK (2008) Modeling of TIG welding and abrasive flow machining processes using radial basis function networks. Int J Adv Manuf Technol 37:937–952

Khorasani AM, Aghchai AJ, Khorram A (2011) Chatter prediction in turning process of conical workpieces by using case-based resoning (CBR) method and taguchi design of experiment. Int J Adv Manuf Technol 55:457–464

Panneerselvam K, Aravindan S, Noorul Haq A (2009) Hybrid of ANN with genetic algorithm for optimization of frictional vibration joining process of plastics. Int J Adv Manuf Technol 42:669–677

Sanjari M, Karimi Taheri A, Movahedi MR (2009) An optimization method for radial forging process using ANN and Taguchi method. Int J Adv Manuf Technol 40:776–784

Simpson TW, Poplinski JD, Koch PN, Allen JK (2001) Metamodels for computer-based engineering design: survey and recommendations. Eng Comput 17:129–179

Liu SJ, Hsieh MH (2007) Residual wall thickness distribution at the transition and curve sections of water-assisted injection molded tubes. Int Polym Proc 22:82–89

Kennedy J, Eberhart RC (1995) In: proceedings of IEEE international conference on neural networks. IEEE service center, Piscataway

Deng YM, Zheng D, Lu XJ (2008) Injection moulding optimisation of multi-class design variables using a PSO algorithm. Int J Adv Manuf Technol 39:690–698

Che ZH (2010) PSO-based back-propagation artificial neural network for product and mold cost estimation of plastic injection molding. Comput Ind Eng 58:625–637

Xu G, Yang ZT, Long GD (2012) Multi-objective optimization of MIMO plastic injection molding process conditions based on particle swarm optimization. Int J Adv Manuf Technol 58:521–531

Wang HS, Wang YN, Wang YC (2013) Cost estimation of plastic injection molding parts through integration of PSO and BP neural network. Expert Syst Appl 40(2):418–428

Yang JG, Zhou XH, Niu Q (2012) Residual wall thickness study of variable cross-section tube in water-assisted injection molding. Int Polym Proc 27:584–590

Liu SJ, Chang CY (2003) The influence of processing parameters on thin-wall gas assisted injection molding of thermoplastic materials. J Reinf Plast Comp 22(8):711–731

Yang C, Hung SW (2004) Modeling and optimization of a plastic thermoforming process. J Reinf Plast Comp 23:109–121

Ozcelik B, Erzurumlu T (2006) Comparison of the warpage optimization in the plastic injection molding using ANOVA, neural network model and genetic algorithm. J Mater Process Tech 171:437–445

Chen WC, Tai PH, Wang MW, Deng WJ, Chen CT (2008) A neural network-based approach for dynamic quality prediction in a plastic injection molding process. Expert Syst Appl 35:843–849

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, J.G., Zhou, X.H. & Luo, G.P. Study of water penetration length and processing parameters optimization in water-assisted injection molding. Int J Adv Manuf Technol 69, 2605–2612 (2013). https://doi.org/10.1007/s00170-013-5233-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5233-1