Abstract

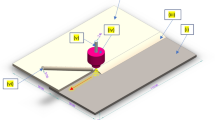

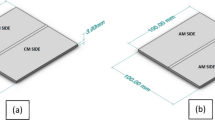

Laser lap welding–brazing of AZ31B Mg alloy to Zn-coated dual phase 980 steel using Mg-based filler was performed. The microstructures at the brazed side were characterized. Fracture behavior was then investigated by in situ scanning electron microscopy observation. The results indicated that heterogeneous reaction layers formed along the interface between the seam and the steel, which had a significant influence on the fracture behavior. Thick and diverse morphologies of reaction products were observed at the seam head and the seam root, where the crack initiated during in situ tensile test. The crack from the seam head then propagated along the Mg-Zn reaction layer/the original Fe-Al phase smoothly due to their weak bonding. When the crack propagated to the direct laser irradiation zone, the newly formed Fe-Al phase at the interface played a positive role in inhibiting the crack propagation, making the crack deflect into the seam zone. Owing to this, the joint strength was ultimately enhanced to 200 N/mm. While the crack from the seam root just propagated into the seam and contributed little to the failure of joint.

Similar content being viewed by others

References

Kulekci MK (2008) Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol 39:851–865

Li CB, Liu LM (2012) Investigation on weldability of magnesium alloy thin sheet T-joints: arc welding, laser welding, and laser-arc hybrid welding. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4145-9

Padmanaban G, Balasubramanian V (2010) An experimental investigation on friction stir welding of AZ31B magnesium alloy. Int J Adv Manuf Technol 49:111–121

Ren DX, Liu LM, Li YF (2011) Investigation on overlap joining of AZ61 magnesium alloy: laser welding, adhesive bonding, and laser weld bonding. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3683-x

Mahendran G, Balasubramanian V, Senthilvelan T (2009) Developing diffusion bonding windows for joining AZ31B magnesium and copper alloys. Int J Adv Manuf Technol 42:689–695

Elthalabawy WM, Khan TI (2011) Eutectic bonding of austenitic stainless steel 316L to magnesium alloy AZ31 using copper interlayer. Int J Adv Manuf Technol 55:235–241

Ghany KA, Rafea HA, Newishy M (2006) Using a Nd:YAG laser and six axes robot to cut zinc-coated steel. Int J Adv Manuf Technol 28:1111–1117

Chen YC, Nataka K (2010) Effect of surface states of steel on microstructure and mechanical properties of lap joints of magnesium alloy and steel by friction stir welding. Sci Technol Weld Joi 15:293–298

Chen YC, Nataka K (2009) Effect of tool geometry on microstructure and mechanical properties of friction stir lap welded magnesium alloy and steel. Mater Des 30:3913–3919

Jana S, Hovanski Y, Grant GJ (2010) Friction stir lap welding of magnesium alloy to steel: a preliminary investigation. Metall Mater Trans A 41:3173–3182

Liu L, Xiao L, Feng JC, Tian YH, Zhou SQ, Zhou Y (2010) The mechanisms of resistance spot welding of magnesium and steel. Metall Mater Trans A 41:2651–2661

Mei LF, Chen GY, Jin XZ, Zhang Y, Wu Q (2009) Research on laser welding of high-strength galvanized automobile steel sheets. Opt Laser Eng 47:1117–1124

Wu Q, Gong JK, Chen GY, Xu LY (2008) Research on laser welding of vehicle body. Opt Laser Technol 40:420–426

Ribolla A, Damoulis GL, Batalha GF (2005) The use of Nd:YAG laser weld for large scale volume assembly of automotive body in white. J Mater Process Tech 164–165:1120–1127

Hamidinejad SM, Hasanniya MH, Salari N, Valizadeh E (2002) CO2 laser welding of interstitial free galvanized steel sheets used in tailor welded blanks. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4005-7

Chen YB, Chen SH, Li LQ (2009) The effect of heat input on microstructure and mechanical property of Al/Ti joints by rectangular spot laser welding-brazing method. Int J Adv Manuf Technol 44:265–272

Chen HC, Pinkerton AJ, Li L (2011) Fibre laser welding of dissimilar alloys of Ti-6Al-4V and Inconel 718 for aerospace applications. Int J Adv Manuf Technol 52:977–987

Wahba M, Katayama S (2012) Laser welding of AZ31B magnesium alloy to Zn-coated steel. Mater Des 35:701–706

Nasiri AM, Li L, Kim SH, Zhou Y, Weckman DC, Nguyen TC (2011) Microstructure and properties of laser brazed magnesium to coated steel. Weld J 90(11):211–219

Qi XD, Song G (2010) Interfacial structure of the joints between magnesium alloy and mild steel with nickel as interlayer by hybrid laser-TIG welding. Mater Des 31:605–609

Liu LM, Liu XJ, Liu SH (2006) Microstructure of laser-TIG hybrid welds of dissimilar Mg alloy and Al alloy with Ce as interlayer. Scripta Mater 55:383–386

Liu LM, Qi XD (2010) Strengthening effect of nickel and copper interlayer on hybrid laser-TIG welded joints between magnesium alloy and mild steel. Mater Des 31:3960–3963

Chen YB, Chen SH, Li LQ (2011) Influence of interfacial reaction layer morphologies on crack initiation and propagation in Ti/Al joint by laser welding-brazing. Mater Des 31:227–233

Qiu R, Iwamoto C, Satonaka S (2009) In situ scanning electron microscopy observation of fracture crack propagation in the welding interface between aluminium alloy and steel. Mater Sci Tech 25(10):1189–1192

Marder AR (2000) The metallurgy of zinc-coated steel. Prog Mater Sci 45:191–271

Xie J (2002) Dual beam laser welding. Weld J 81:223–230

Li LQ, Liu DJ, Chen YB, Wang CM, Li FQ (2009) Electron microscopy study of reaction layers between single-crystal WC particle and Ti-6Al-4V after laser melt injection. Acta Mater 57:3606–3614

Zhang HT, Feng JC, He P, Hackl H (2007) Interfacial microstructure and mechanical properties of aluminium/zinc-coated steel joints made by a modified metal inert gas welding-brazing process. Mater Charact 58:588–592

Zhang HT, Liu JK (2011) Microstructure characteristics and mechanical property of aluminum alloy/stainless steel lap joints fabricated by MIG welding-brazing process. Mater Sci Eng, A 528:6179–6185

Song JL, Lin SB, Yang CL, Ma GC, Liu H (2009) Spreading behavior and microstructure characteristics of dissimilar metals TIG welding-brazing of aluminum alloy to stainless steel. Mater Sci Eng, A 509:31–40

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, C.W., Li, L.Q., Chen, Y.B. et al. Interfacial microstructure and fracture behavior of laser welded–brazed Mg alloys to Zn-coated steel. Int J Adv Manuf Technol 68, 1179–1188 (2013). https://doi.org/10.1007/s00170-013-4910-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-4910-4