Abstract

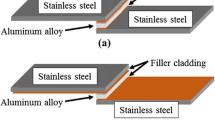

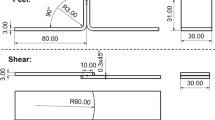

Research is being conducted on the use of shape memory alloys, in particular NiTi, in civil engineering, due to the superelastic behavior of NiTi which can be used for damping. In this particular application, NiTi has to be joined to steel, which constitutes a major difficulty due to the considerably different properties of materials involved and the poor weldability of NiTi. Brazing was investigated for this application, since it is an economic and efficient process to joint dissimilar materials. This paper presents a study on the mechanical behavior in the superelastic regime of dissimilar NiTi/steel joints and the feasibility of a nondestructive method based on eddy currents to characterize the weld metal. Brazed joints in lap configuration were produced with a 20 % Ag braze alloy and tested under fatigue conditions in the superelastic regime. Lap joints of steel rods to NiTi ribbons have undergone up to 60 cycles of load/unload without rupture at a maximum load of the superelastic plateau close to the pull-out load of the joint. Measurements of the electrical impedance, with a helicoidal cylindrical coil along the lap joint, allowed the identification of the location of the joint, with a good spatial resolution characterizing the morphology of the brazed joints.

Similar content being viewed by others

References

Janke L, Czaderski C, Motavalli M, Ruth J (2005) Applications of shape memory alloys in civil engineering structures—overview, limits and new ideas. Mater Struct 38:578–592

Song G, Ma N, Li H-N (2006) Applications of shape memory alloys in civil structures. Eng Struct 28:1266–1274

Song G, Mo YL, Otero K, Gu H (2006) Health monitoring and rehabilitation of a concrete structure using intelligent materials. Smart Mater Struct 15:309–314

Masoud Motavalli, Christoph Czaderski, Andrea Bergamini, Lars Janke (2009) Shape memory alloys for civil engineering structures—on the way from vision to reality. Arch Civ Eng Environ 4:81–94

Santos FP (2011) Vibration control with shape-memory alloys in civil engineering structures. PhD thesis, FCT-UNL. Available at: http://run.unl.pt/handle/10362/5610. Accessed 26 June 2012

Otsuka K, Wayman CM (1998) Shape memory materials, 1st edn. Cambridge University Press, Cambridge

Lagoudas DC (2008) Shape memory alloys: modeling and engineering applications, 1st edn. Springer, New York

Miranda RM, Braz Fernandes FM, Craciunescu CM, Quintino L, Alberty Vieira L (2011) Shape memory alloys: existing and emerging applications. In: Wythers MC (ed) Advances in materials science research, volume 6. Nova Science Publishers, Hauppauge, Chapter 7; ISBN: 978-1-61209-116-7

Shahmir H, Nili-Ahmadabi M, Naghdi F (2011) Superelastic behavior of aged and thermomechanical treated NiTi alloy at Af + 10 °C. Mater Des 32:365–370

Qiu XM, Li MG, Sun DQ, Liu WH (2006) Study on brazing of TiNi shape memory alloy with stainless steels. J Mater Process Technol 176:8–12

Pouquet J, Miranda RM, Quintino L, Williams S (2012) Dissimilar laser welding of nitinol to stainless steel. Int J Adv Mater Technol 61:205–212

Naidich YV et al (2008) Liquid metal wettability and advanced ceramic brazing. J Eur Ceram Soc 28:717–728

Santos TG, Miranda RM, Vilaça P, Teixeira J (2011) Modification of electrical conductivity by friction stir processing in aluminium alloys. Int J Adv Manuf Technol 57:511–519. doi:10.1007/s00170-011-3308-4

Santos TG, Vilaça P, Miranda RM (2011) Electrical conductivity field analysis for evaluation of FSW joints in AA6013 and AA7075 alloys. J Mater Process Technol 211:174–180

Alberty Vieira L, Braz Fernandes FM, Silva RJC, Quintino L, Cuesta A, Ocaña JL (2011) Mechanical behaviour of Nd:YAG laser welded superelastic NiTi. Mater Sci Eng, A 528(16–17):5560–5565

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santos, T.G., Fernandes, F.B., Bernardo, G. et al. Analyzing mechanical properties and nondestructive characteristics of brazed joints of NiTi shape memory alloys to carbon steel rods. Int J Adv Manuf Technol 66, 787–793 (2013). https://doi.org/10.1007/s00170-012-4366-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4366-y