Abstract

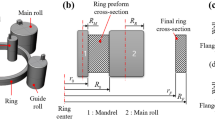

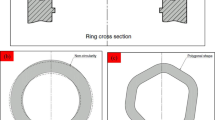

An accurate prediction for the diameter expansion is quite essential for the ring rolling with large diameter since it determines the compatibility between the work rolls and the deformed ring in kinematics, so that the rolling stability and the final forming quality of the ring are influenced. A new mathematical model for predicting the diameter expansion of the flat ring in the radial–axial rolling process has been proposed, in which the variation of cross section, the particularity of initial rolling phase, and the effect of slip are all taken into consideration. Based on the proposed mathematical model, a 3D-FEM model for the radial–axial ring rolling process has been developed, and the corresponding experimentation has also been carried out. The diameter expansion in the simulation shows a good agreement with that in the experimentation. The forming quality comparison concerning the circularity, coaxiality, and tilting of the rolled ring has been executed between the former and new proposed method. The result indicates that the new mathematical method is very helpful to control the forming stability and hence improve the ring rolling quality significantly.

Similar content being viewed by others

References

Mamalis AG, Hawkyard JB, Johnson W (1976) Spread and flow patterns in ring rolling. Int J Mech Sci 18:11–16

Johnson W, Needham G (1968) Experiments on ring rolling. Int J Mech Sci 10:95–113

Mamalis AG, Hawkyard JB, Johnson W (1976) On the pressure distribution between stock and rolls in ring rolling. J Mater Eng Sci 18:184–195

Allwood JM, Kopp R, Michels D, Music O, Öztop M, Stanistreet TF, Tekkaya AE, Tiedemman I (2005) The technical and commercial potential of an incremental ring rolling process. CIRP Ann-Manuf Techn 54:233–236

Lugora CF, Bramiley AN (1987) Analysis of spread in ring rolling. Int J Mech Sci 29:149–157

Mamalis AG, Hawkyard JB, Johnson W (1976) Pressure distribution, roll force and torque in cold ring rolling. J Mech Eng Sci 18:196–209

Hawarkyard JB, Johnson W, Kirkland J, Appleton E (1973) Analyses for roll force and torque in ring rolling with some supporting experiments. Int J Mech Sci 15:873–893

Qan DS, Hua L, Pan LB (2009) Research on gripping conditions in profile ring rolling of raceway groove. J Mater Process Tech 209:2794–2802

Hua L, Zuo ZJ, Lan J (2007) Research on following motion rule of guide roller in cold rolling groove ball ring. J Mate Process Tech 187–188:743–746

Davey K, Ward MJ (2003) An ALE approach for finite element ring-rolling simulation of profiled rings. Mater Process Tech 139:559–566

Davey K, Ward MJ (2002) A practical method for finite element ring rolling simulation using the ALE flow formulation. Int J Mech Sci 44:165–190

Youngsoo Y, Youngsoo K, Nasoo K, Jongchan L (2003) Prediction of spread, pressure distribution and roll force in ring rolling process using rigid-plastic finite element method. J Mate Process Tech 140:478–486

Joun MS, Chung JH, Shivpuri R (1998) An axisymmetric forging approach to preform design in ring rolling using a rigid-viscoplastic finite element method. Int J Mach Tool Manu 38:1183–1191

Ranatunga V, Gunasekera JS, Vaze SP, Souza UD (2004) Three-dimensional UBET simulation tool for seamless ring rolling of complex profiles. J Manu Process 6:179–186

Moon HK, Lee MC, Joun MS (2008) Predicting polygonal-shaped defects during hot ring rolling using a rigid-viscoplastic finite element method. Int J Mech Sci 50:306–314

Anjami N, Basti A (2010) Investigation of rolls size effects on hot ring rolling process by coupled thermo-mechanical 3D-FEA. J Mater Process Tech 210:1364–1377

Forouzan MR, Salimi M, Gadala MS, Aljawi AA (2003) Guide roll simulation in FE analysis of ring rolling. J Mater Process Tech 142:213–223

Li LY, Yang H, Guo LG, Sun ZC (2008) A control method of guide rolls in 3D-FE simulation of ring rolling. J Mater Process Tech 205:99–110

Guo LG, Yang H (2008) Key technologies for 3D-FE modeling of radial–axial ring rolling process. Mater Sci Forum 575–578:367–372

Guo LG, Yang H (2004) Simulation for guide roll in 3D-FE analysis of cold ring-rolling. Mater Sci Forum 471–472:760–764

Liu D, Wan ZY, Fu MJ (2008) Kinematics analysis in radial–axial rolling. Chin J Mech Eng 19:466–468 (in Chinese)

Hua L, Zhao ZZ (1997) The extremum parameters in ring rolling. J Mater Process Tech 69:273–276

Hua L, Huang XG, Zhu CD (2001) Theory and technology of ring rolling. China Machine Press, Beijing (in Chinese)

Acknowledgments

The authors would like to thank for the support of Ministry of Science and Technology Sino-German Cooperation Project (2010DFA51860), Natural Science Foundation Project of CQ (CSTC, 2010BB4245) and the Fundamental Research Funds for the Central Universities of China (CDJZR1013 0019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, W., Yang, X., Gong, X. et al. A new mathematical model for predicting the diameter expansion of flat ring in radial–axial ring rolling. Int J Adv Manuf Technol 60, 913–921 (2012). https://doi.org/10.1007/s00170-011-3666-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3666-y