Abstract

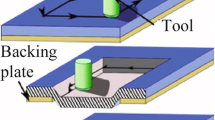

The aim of this paper is to provide an overview into the development and application of single point incremental forming in rapid prototyping and rapid manufacturing of polymer sheet products that will enable the readers to recognize the key influential variables, to identify the process feasibility window, to diagnose possible sources of failure and to understand the routes for selecting the most appropriate materials and operative conditions. The methodology draws from independent determination of mechanical properties and formability limits of polymers to rapid prototyping of truncated conical and pyramidal parts. The investigation is supported by circle grid analysis. Results and observations are explained in the light of theoretical framework based on membrane analysis that is capable of modelling the cold plastic deformation of polymers with pressure-sensitive yield surfaces. The results show that the single point incremental forming of polymer sheets, performed on conventional CNC machining centres, is a cost-effective innovative technology for product development in a manufacturing environment. Applications may span from products with very high depths, taking advantage of the excellent formability of polyethylene terephthalate, to applications in polycarbonate where transparency is kept during cold forming.

Similar content being viewed by others

References

Franzen V, Kwiatkowski L, Martins PAF, Tekkaya AE (2008) Single point incremental forming of PVC. J Mater Process Tech 209:462–469

Jeswiet J, Micari F, Hirt G, Bramley A, Duflou J, Allwood J (2005) Asymmetric single point incremental forming of sheet metal. CIRP Annals—Manufacturing Technology 54:623–650

Le VS, Ghiotti A, Lucchetta G (2008) Preliminary studies on single point incremental forming for thermoplastic materials. In: 11th ESAFORM Conference on Material Forming—ESAFORM2008. Lyon, France

Martins PAF, Kwiatkowski L, Franzen V, Tekkaya AE, Kleiner M (2009) Single point incremental forming of polymers. CIRP Annals—Manufacturing Technology 58:229–232

Silva MB, Alves LM, Martins PAF (2010) Single point incremental forming of PVC: experimental findings and theoretical interpretation. Eur J Mech Solid 29:557–566

Whitney W, Andrews RD (1967) Yielding of glassy polymers: volume effects. J Polymer Sci C 16:2981–2990

Raghava RS, Caddell RM, Yeh GSY (1973) The macroscopic yield behaviour of polymers. J Mater Sci 8:225–232

Caddell RM, Raghava RS, Atkins AG (1974) Pressure dependent yield criteria for polymers. Mater Sci Eng 13:113–120

Silva MB, Skjoedt M, Atkins AG, Bay N, Martins PAF (2008) Single point incremental forming & formability/failure diagrams. Journal of Strain Analysis for Engineering Design 43:15–36

Alves LM, Nielsen CV, Martins PAF (2011) Revisiting the fundamentals and capabilities of the stack compression test. Experimental Mechanics. doi:10.1007/s11340-011-9480-5

Bucknall CB (2007) New criterion for craze initiation. Polymer 48:1030–1041

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marques, T.A., Silva, M.B. & Martins, P.A.F. On the potential of single point incremental forming of sheet polymer parts. Int J Adv Manuf Technol 60, 75–86 (2012). https://doi.org/10.1007/s00170-011-3585-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3585-y