Abstract

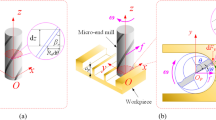

Thread milling offers interesting possibilities for machining internal or external threads. This machining technique uses a mill with a triangular profile for metric threads and a helical interpolation strategy. Thus, the uncut chip thickness cannot be easily evaluated from a simplified approach. The present study deals with a model for calculating uncut chip thickness during internal thread milling. This step is needed to understand and model the cutting forces. The model developed uses the geometrical definitions of the mill and takes into account the milling mode and the cutting conditions. The link with the interferences between the tool and the thread is also established and corroborates a previous study. A full analytical formulation of the problem is proposed, and results from different milling settings are presented.

Similar content being viewed by others

References

Koelsch JR (2005) Thread milling takes on tapping. Manuf Eng 115:77–83

Halas D (1996) Tapping vs thread milling. Tool Prod 62:99–102

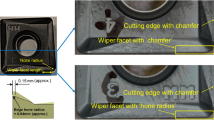

Fromentin G, Poulachon G (2009) Modeling of interferences during thread milling operation. Int J Adv Manuf Technol. doi:10.1007/s00170-009-2372-5

Fromentin G, Poulachon G (2009) Geometrical analysis of thread milling—Part 1: evaluation of tool angles. Int J Adv Manuf Technol (in press)

Armarego EJA, Herath AB (2000) Predictive models for machining with multi-edge form tools based on a generalised cutting approach. Annals CIRP 29(1):25–30

Armarego EJA (2000) The unified generalised mechanics of cutting approach—a step towards a house of predictive performance models for machining operations. 3rd International Workshop on the Modelling of Machining Operations, Sydney, Australia, 20 August 2000, 6–24

Mezentsev OA, Zhu R, DeVor RE, Kapoor SG, Kline WA (2002) Use of radial forces for fault detection in tapping. Int J Mach Tools Manuf 42:470–488

Armarego EJA, Chen MNP (2002) Predictive cutting models for the forces and torque in machine tapping with straight flute taps. Annals CIRP 51:75–78

Araujo AC, Silveira JL, Jun MBG, Kapoor SG, DeVor R (2006) A model for thread milling cutting forces. Int J Mach Tools Manuf 46:2057–2065

ISO 68-1:1998 standard, ISO general purpose screw threads—Basic profile—Part 1: metric screw threads

Fang N (2005) Tool-chip friction in machining with a large negative rake angle tool. Wear 258(5–6):890–897

Bar G (1997) Curvatures of enveloped helicoids. Mech Mach Theory 32(1):111–120

Kang SK, Ehmann KF, Lin C (1996) A CAD approach to helical groove machining Part 1: mathematical model and model solution. Int J Mach Tools Manuf 36(1):141–153

Chiang CJ, Fong ZH, Tseng JT (2009) Computerized simulation of thread form grinding process. Mech Mach Theory 44(4):685–696

Redonnet JM, Rubio W, Dessein G (1998) Side milling of ruled surfaces: Optimum positioning of the milling cutter and calculation of interference. Int J Adv Manuf Technol 14(7):459–465

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fromentin, G., Poulachon, G. Geometrical analysis of thread milling—part 2: calculation of uncut chip thickness. Int J Adv Manuf Technol 49, 81–87 (2010). https://doi.org/10.1007/s00170-009-2401-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2401-4