Abstract

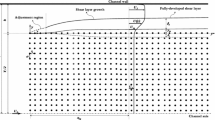

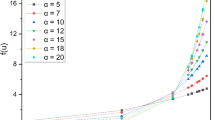

A new generalized upper-bound solution for the equal-channel angular extrusion (ECAE) process is presented in this paper. Using mathematical definition of Bezier curves, a streamline was formulated to define a generalized deforming region. Based on this deforming region, a kinematically admissible velocity field was obtained from which upper-bound solutions were computed. By changing the parameters defining the Bezier-shaped streamline which in turn defines the deforming region, the optimization of the upper-bound solution was carried out. Equal-channel angular extrusion through a 90° bend was considered. Using the formulation presented in here, it was possible to predict the shape of the dead metal zone and its variation with frictional conditions. Unlike previous work in which a fixed circular shape had been assumed for the dead metal zone, in this paper, a generalized shaped Bezier curve was used. The optimum value of the extrusion pressure for ECAE was obtained and compared with both experimental and theoretical data from previous works. It was concluded that the present solution gave an improvement over all previous works and the authors’ results were closer to experimental data.

Similar content being viewed by others

References

Altan BS, Purcek G, Miskioglu I (2005) An upper-bound analysis for equal-channel angular extrusion. J Mater Process Technol 168:137–146

Eivani AR, Karimi Taheri A (2007) An upper bound solution of ECAE process with outer curved corner. J Mater Process Technol 182:555–563. doi:10.1016/j.jmatprotec.2006.09.021

Sandim HRZ, Bernardi HH, Verlinden B, Raabe D (2007) Equal channel angular extrusion of niobium single crystals. Mater Sci Eng A 467:44–52. doi:10.1016/j.msea.2007.02.086

Li A, Gazder SA, Beyerlein IJ, Davies CHJ, Pereloma EV (2007) Microstructure and texture evolution during equal channel angular extrusion of interstitial-free steel: effects of die angle and processing route. Acta Mater 55:1017–1032. doi:10.1016/j.actamat.2006.09.022

Zhang ZJ, Son IH, Im YT, Park JK (2007) Finite element analysis of plastic deformation of CP-Ti by multi-pass equal channel angular extrusion at medium hot-working temperature. Mater Sci Eng A 447:134–141. doi:10.1016/j.msea.2006.10.068

Tham YW, Fu MW, Hng HH, Yong MS, Lim KB (2007) Bulk nanostructured processing of aluminum alloy. J Mater Process Technol 192–193:575–581. doi:10.1016/j.jmatprotec.2007.04.076

Petryk H, Stupkiewicz S (2007) A quantitative model of grain refinement and strain hardening during severe plastic deformation. Mater Sci Eng A 444:214–219. doi:10.1016/j.msea.2006.08.076

Kecskes LJ, Cho KC, Dowding RJ, Schuster BE, Valiev RZ, Wei Q (2007) Grain size engineering of bcc refractory metals: top-down and bottom-up—application to tungsten. Mater Sci Eng A 467:33–43. doi:10.1016/j.msea.2007.02.099

Su CW, Lu L, Lai MO (2006) A model for the grain refinement mechanism in equal channel angular pressing of Mg alloy from microstructural studies. Mater Sci Eng A 434:227–236. doi:10.1016/j.msea.2006.06.103

Hasani A, Lapovok R, To’th LS, Molinari A (2008) Deformation field variations in equal channel angular extrusion due to back pressure. Scr Mater 58:771–774. doi:10.1016/j.scriptamat.2007.12.018

Eivani AR, Karimi Taheri A (2008) The effect of dead metal zone formation on strain and extrusion force during equal channel angular extrusion. Comput Mater Sci 42:14–20. doi:10.1016/j.commatsci.2007.06.001

Abrinia K, Bloorbar H (2000) A new improved upper bound solution for the extrusion of shaped sections using CAD techniques. COMPLAS VI Conference, Barcelona, Spain

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abrinia, K., Mirnia, M.J. A new generalized upper-bound solution for the ECAE process. Int J Adv Manuf Technol 46, 411–421 (2010). https://doi.org/10.1007/s00170-009-2103-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2103-y