Abstract

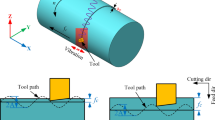

There are two drawbacks in the performance of the resonant vibration cutting tools currently available. One is that the vibration frequency cannot be changed arbitrarily and the other is that the cutting force is low. It is impossible to turn mirror plates with many kinds of materials using these resonant vibration cutting tools because they cannot match the desirable turning speeds that correspond to the machined materials and the vibration frequency needs to be increased or decreased to obtain the desired surface roughness. Resonant vibration cutting tools do not allow the vibration frequency to be set arbitrarily. The small cutting force of these tools also causes some difficulties in diamond turning of metals other than soft metals such as aluminum and copper. In this research, we developed a vibration cutting tool that can generate two-dimensional vibration shapes without distortion by placing two piezoelectric actuators at right angles. This tool can machine the many kinds of mirror plates with different materials to the desired surface roughness. It is also possible to machine hard materials such as mold steels because the amplitudes of the vibrations do not decrease, even when large cutting forces are required. In this paper, we describe the design of the nonresonant vibration cutting tool, and show by the diamond turning of oxygen-free copper and aluminum that our nonresonant vibration cutting tool can machine desired shapes. Finally, it is verified by actual machining experiments that the proposed vibration cutting tool can machine hardened mold steels such as STAVAX with HRC 54.

Similar content being viewed by others

References

Shamoto E, Moromoto Y, Moriwaki T (1996) Elliptical vibration cutting (first report: cutting principle and basic performance. J Jpn Soc Precis Eng 62(8):1127–1131

Shamoto E, Moriwaki T (1999) Ultraprecision diamond cutting of hardened steel by applying elliptical vibration cutting. Ann CIRP 48(1):441–444

Shamoto E, Song Y, Yoshida H (2003) Development of elliptical vibration cutting machine by utilizing mechanical vibrator. J Jpn Soc Precis Eng 69(4):542–548

Gan J, Wang X, Zhou M, Ngoi B, Zhong Z (2003) Ultraprecision diamond turning of glass with ultrasonic vibration. Int J Adv Manuf Technol 21(12):952–955

Kim J-D, Choi I-H (1998) Characteristics of chip generation by ultrasonic vibration cutting with extremely low cutting velocity. Int J Adv Manuf Technol 14(1):2–6

Shamoto E, Moromoto Y, Moriwaki T (1999) Elliptical vibration cutting (second report): study on effects of vibration conditions. J Jpn Soc Precis Eng 65(3):411–417

Paros JM, Weisbord L (1965) How to design flexure hinges. Machine Design 27:151–156

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, HS., Kim, SI., Lee, KI. et al. Development of a programmable vibration cutting tool for diamond turning of hardened mold steels. Int J Adv Manuf Technol 40, 26–40 (2009). https://doi.org/10.1007/s00170-007-1311-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-1311-6