Abstract

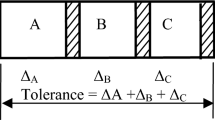

Quality is an important aspect of any manufacturing process. Only high quality products can survive in the market. The consumer not only wants quality, precision and trouble-free products, but also wants them at attractive prices. When a product consists of two or more components, the quality of that product depends upon the quality of the mating parts. The mating parts may be manufactured using different machines and processes with different standard deviations. Therefore, the dimensional distributions of the mating parts are not similar. This results in clearance or interference between the mating parts. In some high precision assemblies, it may not be possible to have closer assembly clearance variation with interchangeable system. Selective assembly meets the above requisite and gives an enhanced solution. Selective assembly is a method of obtaining high precision assemblies from relatively low precision components. In this paper, a new selective assembly method is proposed to minimize the clearance variation and surplus parts for a complex assembly which consists of the components viz. piston, piston ring. In this assembly, each component will have more than one quality characteristic contributing for the assembly, for e.g., piston diameter will assemble with cylinder inner diameter; piston groove diameter will assemble with piston ring inner diameter, etc. In selective assembly each quality characteristic will fall in different groups. Non-dominated sorting genetic algorithm (NSGA) is used to find the best combination to obtain the minimum clearance variation in this assembly.

Similar content being viewed by others

References

Mansoor E (1961) Selective assembly-its analysis and applications. Int J Prod Res 1(1):13–24

Rabinovich L (1968) Improving the characteristics of selective assembly. Russ Eng J 48:54–59

Rabinovich LA, Kesoyan AG (1980) Investigation the rational sorting accuracy for selective assembly of precision units. Russ Eng J 60:50–53

Rubenchik V Ya, Mentov KV, Novikov VV (1979) Automatic sorting of rings by size prior to selective assembly. Measurement Technology 22(1):71–73

Allen Pugh G (1986) Partitioning for selective assembly. Computers and Industrial Engineering, Vol.11, No. 1–4, Proceedings of the 8th Annual Conference on Computers and Industrial Engineering, Orlando, FL, U.S.A., pp 175–179, Mar 19–21

Desmond D, Setty C (1962) Simplification of selective assembly. Int J Prod Res 1(3):3–18

Boyer DE, Nazemetz JW (1985) Introducing statistical assembly-a means of producing high precision assemblies from low precision components. Int Ind Eng Conf Proc, pp 652–670

Allen Pugh G (1992) Selective assembly with components of dissimilar variance. Computers and Industrial Engineering 23(1–4):487–491

Allen Pugh G (1986b) Group formation in selective assembly. SME Ultratech Conference Proceedings, pp 2.117–2.123

Fujino Y (1987) Matching problem when lot size is large. Rep Stat Appl Res, UJSE 34:1–10

Berzak N (1992) Selective robotic assembly. 4th International Conference on Design theory methodology, Scottdale, Ariz. U.S.A., ASME Design Engineering Division 48:71–75

Yamada Y (1994) Combinatorial optimization of selective assembly in continuous production. Communications in Operations Research Society of Japan 39:556–560

Arai T (1992) A simulation system on assembly accuracy. Annals CIRP 41:37–40

Iyama T Mizuno, Goto S, Kogo T (1995) A race matching method for ball bearing manufacture. JSME, International Journal Series C 38:167–171

Fang XD, Zhang Y (1995) A new algorithm for minimizing the surplus parts in selective assembly. Computers and Industrial Engineering 28(2):341–350

Fang XD, Zhang Y (1996) Assuring the matchable degree in selective assembly via a predictive model based on set theory and probability method. J Manuf Sci Eng, Transactions of the ASME 118:252–258

Coullard CR, Gamble AB, Jones PC (1998) Matching problems in selective assembly operations. Ann Oper Res 76:95–107

Zhang Y, Low YS, Fang XD (1998) PCI-based tolerance as an interface between design specifications and statistical quality control. Computers Industrial Engineering 35(1–2):201–204

Ka Ching Chan, Richard I (1998–99) Linn ‘A grouping method for selective assembly of parts of dissimilar distributions. Qual Eng 11(2):221–234

Kannan SM, Jayabalan V (2001) A new grouping method for minimizing the surplus parts in Selective Assembly. Qual Eng 14(1):67–75

Kannan SM, Jayabalan V (2002) Manufacturing mean design for selective assembly to minimize surplus parts. ICQR, pp 259–264

Kannan SM, Jayabalan V (2001) A new grouping method to minimize surplus parts in selective assembly for complex assemblies. Int J Prod Res 39(9):1851–1864

Kannan SM, Jayabalan V (2001) Selective assembly for minimizing assembly tolerance in linear assembly. 12th ISME Conference, pp 420–425

Kannan SM, Jayabalan V, Jeevanantham K (2003) Genetic algorithm for minimizing assembly variation in Selective Assembly. Int J Prod Res 41(14):3301–3313

David Mease Nair, Vijayan N, Agus Sudjivnto (2004) Selective assembly in manufacturing: statistical issues and optimal binning strategies. Technometrices 46(2):165–175

David Goldberg (1989) Genetic algorithms in search optimization and machine learning. Addition Wesley publishing company. Inc, New York

Zbigniew Michalewicz (1996) Genetic algorithms + Evolution programs. Springer-Verlag, Berlin Heidelberg, New York

Kalyanmoy Deb (2003) Multi objective optimization using evolutionary algorithms. John Wiley & Sons, Ltd, England

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asha, A., Kannan, S. & Jayabalan, V. Optimization of clearance variation in selective assembly for components with multiple characteristics. Int J Adv Manuf Technol 38, 1026–1044 (2008). https://doi.org/10.1007/s00170-007-1136-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-1136-3