Abstract

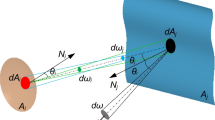

A vision system has been developed to facilitate the pulsed-laser cutting of decorative lace used in various forms of apparel. Existing vision systems for lace cutting utilise back-lighting or top-lighting techniques to create a near-binary image of the lace. This can lead to problems in identifying the lace cutting path accurately. A transmissive illumination system has been modelled and tested that can reveal density information from the lace, and so, provide a more suitable image for identifying cutting points on the lace web. Experimental results have demonstrated that the illumination method can be successfully modelled to ensure even illumination using light emitting diodes (LED).

Similar content being viewed by others

References

Varley DE (1968) John Heathcoat, 1783–1861: founder of the machine-made lace industry. Text Hist 1(1):2–45

Farooq U, King TG, Gaskell PH, Kapur N (2002) A mechatronic approach for automatic inspection of deformable webs. In: Proceedings of the Mechatronics 2002 International Conference, Twente, The Netherlands, June 2002

Sanby C, Norton-Wayne L, Harwood R (1995) The automated inspection of lace using machine vision. Mechatronics 5(2–3):215–231

Bamforth PE, Jackson MR, Williams K (2002) High accuracy automated scalloping of decorative lace. In: Proceedings of the Mechatronics 2002 International Conference, Twente, The Netherlands, June 2002

Jackson MR, Preston ME (1998) Lace cutting for the next millennium. Integr Manuf Syst 9(1):34–40

Russell RA, Wong P (1989) An application of computer vision to lace cutting. Robot Auton Syst 5(2):91–96

Shih C-HV, Sherkat N, Thomas P (1996) An automatic lace trimming process using real-time vision. Real-Time Imaging 2(2):117–130

Jackson MR, Preston ME, Tao LG (1996) Real-time cutting path determination using machine vision-based incremental pattern tracking. Real-Time Imaging 2(4):249–264

Jackson MR, Preston ME, Tao LG (1995) High speed cutting of patterned shapes from fabrics. Mechatronics 5(2–3):197–213

Kimoto I, Yamafuji K (1986) Automation of sealant painting and lace cutting using pattern tracking techniques. Int J Adv Manuf Technol 1(4):101–107

Shih C-HV, Sherkat N, Thomas P (1999) A real-time vision based automatic lace trimming process. In: Proceedings of the IEEE Workshop on Signal Processing Systems (SiPS’99), Taipei, Taiwan, October 1999

Cardarelli AJ, Tao Y, Bernhardt JL, Lee FN (1999) Nondestructive quantification of internal damage in rough rice caused by insects and fungus. Proc SPIE 3543:111–118

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bamforth, P.E., Jackson, M.R. & Williams, K. Transmissive dark-field illumination method for high-accuracy automatic lace scalloping. Int J Adv Manuf Technol 32, 599–607 (2007). https://doi.org/10.1007/s00170-005-0359-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0359-4