Abstract

Most of the studies done on the economic design of control charts focus on a fixed-sampling interval (FSI); however, it has been discovered that variable-sampling-interval (VSI) control charts are substantially quicker in detecting shifts in the process than FSI control charts due to a higher frequency in the sampling rate when a sample statistic shows some indication of a process change. In this paper, an economic design for a VSI moving average (MA) control chart is proposed. The results of a numerical example adopted from an actual case indicate that the loss cost of VSI MA control charts is consistently lower than that of the FSI scheme.

Similar content being viewed by others

Abbreviations

- n :

-

Sampling size for each moving plot

- h a :

-

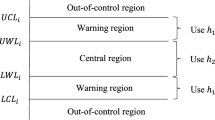

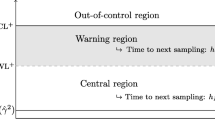

Subsequent sampling interval when preceding sample mean is located at sub-control region I a , a=1,2,...,η

- η :

-

Number of different sampling-interval lengths, η≥2

- k a :

-

Threshold limit expressed in units of \({\sqrt n }{\left( {\overline{x} - \mu _{0} } \right)}/\sigma ,\;\;a = 2,3,...,\eta \)

- k 1 :

-

Control limit expressed in units of \({\sqrt n }{\left( {\overline{x} - \mu _{0} } \right)}/\sigma \)

- µ 0 :

-

Target mean

- σ :

-

True-process standard deviation

- δ :

-

Magnitude of an assignable cause expressed in units of σ

- λ :

-

Occurrence rate of an assignable cause per unit time

- D :

-

Average time taken to find and repair an assignable cause after detection

- e :

-

Time for a sample to be taken, transmitted to laboratory, and results phoned back to process control room

- M :

-

Income reduction when μ=μ 0+δσ

- T :

-

Average cost of looking for an assignable cause when a false alarm occurs

- W :

-

Average cost of looking for and repairing an assignable cause when one does exist

- F c :

-

Fixed cost per subgroup of sampling, inspecting, evaluating and plotting

- V c :

-

Variable cost per subgroup of sampling, inspecting, evaluating and plotting

References

Duncan AJ (1956) The economic design of x̄ charts used to maintain current control of a process. J Am Stat A 51:228–242

Duncan AJ (1971) The economic design of x̄ charts when there is a multiplicity of assignable causes. J Am Stat A 66(333):107–121

Saniga EM (1977) Joint economically optimal design of x̄ and R control charts. Manag Sci 24(4):420–431

Lorenzen TJ, Vance LC (1986) The economic design of control charts: a unified approach. Technometrics 28:3–10

Von Collani E (1986) A simple procedure to determine the economic design of an x̄ control chart. J Qual Tech 18:145–151

Banerjee PK, Rahim MA (1988) Economic design of x̄ control charts under Weibull shock models. Technometrics 30:407–414

Von Collani E, Sheil J (1989) An approach to controlling process variability. J Qual Tech 21:87–96

Koo TY, Case KE (1990) Economic design of x̄ control charts for use in monitoring continuous flow processes. Int J Prod R 28:2001–2011

Torng CC, Montgomery DC, Cochran JK (1994) Economic design of the EWMA control charts. Econ Qual C 9:3–23

Ho C, Case E (1994) The economically-based EWMA control chart. Int J Prod R 32:2179–2186

Montgomery DC (2001) Introduction to statistical quality control, 4th edn. Wiley, New York

Chen YS, Yu FJ (2002) Determination of optimal design parameters of moving average control charts. Int J Adv Manuf Technol 21:397–402

Renolds MR, Amin RW, Arnold JW, Nachlas JA (1988) x̄ charts with variable sampling intervals. Technometrics 30:181–192

Parkhideh B, Case KE (1989) The economic design of a dynamic x̄ control chart. IIE Trans 21:313–323

Ohta H, Rahim MA (1997) A dynamic economic model for an x̄ control chart design. IIE Trans 29:481–486

Bai DS, Lee KT (1998) An economic design of variable sampling interval x̄ control charts. Int J Prod E 54:57–64

Rahim MA (1993) Economic design of x̄ control charts assuming Weibull in-control times. J Qual Tech 25:296–305

Reklaitis GV, Ravindran A, Ragsdell KM (1983) Engineering optimization method and applications. Wiley, New York

Acknowledgments

The authors wish to express appreciation for the support by National Sciences Council of the Republic of China, Grant No. NSC90-2218-E-212-001, and to Dr. Cheryl Rutledge for her editorial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, FJ., Wu, HH. An economic design for variable sampling interval MA control charts. Int J Adv Manuf Technol 24, 41–47 (2004). https://doi.org/10.1007/s00170-003-1625-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1625-y