Summaries

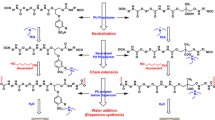

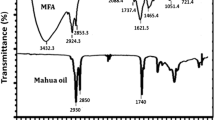

Poly(phthalazione ether nitrile ketone)s (PPENK), modified with NaOH, were studied in order to find a hydrophilic resin with could be used in heat-resistant water-borne coatings. The properties of hydrolysates — HPPENKa (0.5 hours), HPPENKb (1.5 hours) and HPPENKc (3.5 hours) — were measured by differential scanning calorimetry (DSC), thermo-gravimetric analysis (TGA), contract angle (water) and solubility. The structures of the hydrolysates were confirmed by FIIR (Fourier transform infrared spectroscopy) and1H-NMR. The results indicated that the conversion ration of the nitrile groups and the glass transition temperature (79) of the hydrolysates increased, whereas the weight loss ratio of HPPENK decreased as the hydrolysis time was prolonged As expected, the hydrophificity of HPPENK improved greatly (eg when the CN conversion ratio was 93.82%, and the water contact angles decreased from 75.3° for PPENK to 54.4° for HPPENK). By studying the effects of the different reactions of the co-solvents, the reaction temperature and the NaOH concentration on the hydrolysis, it could be concluded that the optimal synthetic technology was of a 6M NaOH solution with DMAc (N,N-dimethylacetamide) as co-solvent at 120°C. Aqueous dispersions based on three modified resins were prepared and their storage stability was as follows: HPPENKc >HPPENKb>HPPENKa. In particular, the HPPENKc dispersion had no settling for more than 30 days and provided good film-forming. The cured film properties of HPPENKc were as follows: pencil rigidity (six hours), thermal impact resistance (300°C, 24 hours), and adhesion (grade 1). Curing agents were applied to the dispersion, such as hexamethoxymethyl melamine (HMMM), epichlorohydrin (ECH), triethanolamine, and glycerol, etc. HMMM and ECH provided excellent curing properties. The co-operating emulsification of (Span) sorbate and (Tween) polyoxyethylene sorbate could improve the stability of the HPPENK dispersion.

Résumé

Des poly(phthalazinone éther nitrile cétone)s (PPENK), modifiés par NaOH on été étdiés afinmde trouver une résine hydrophilique qui soit capable d’étre utilisée dans les revétements hydrodiluables qui résistent à la chaleur. Les propriétés des hydrolysates- HPPENKa (0,5 heures), HPPENKb (1,5 heures), et HPPENKc (3,5 heures)- ont été mesurées grâce à la calorimétrie par analyse différentielle (DSC), la méthode thermogravimétrique (TGA), l’angle de contact (eau) et la solubilité. Les structures des hydrosates ont été confirmées par FTIR (spectrométrie infrarouge par transformée de Fourier) et par spectroscopie 1H-NMR. Les résultats ont indiqué que la proportion de conversion des groupes nitriles aussi bien que la température de latransition vitreuse (Tg) des hydrosates ont augmenté, tandis que la proportion de la perte de poids des HPPENK a diminué avec la prolongation du temps de l’hydrolyse. Comme prévu, l’hydrophilicité des HPPENK abeaucoup amélioré (par exemple quand la proportion de conversion (CN était de 98.82%, et quand les angles de contact (eau) ont diminué de 75.3° pour les HPPENK jusquà 54.4° pour les HPPENK). Grâce à l’étude des effets sur l’hydrolyse des différentes réactions des co-solvants, de la température de la réaction, et de la concentration du NaOH, on a pu conclure que la technoloqie optimale synthétique était celle d’une solution 6M NaOH avec le DMAc (N,N-diméthylacétamide) comme co-solvant à 120°. Des dispersions aqueuses, basées sur trois résines modifiées, ont été préparées et leur stabilité au stockage était HPPENKc>HPPENKb<HPPENKa. En particulier, la dispersion HPPENKc n’avait pas de dépôt de sédiment pendant plus de 30 jours et a fait preuve de la capacité de former un bon film. Pour le HPPENKc les propriétés du film séché étaient dureté de crayon (six heutes), résistance à impact thermique (300°, 24 heures) et adhérence (grade 1). On à appliqué à la dispersion des agents de séchage tels que l’Hexaméthoxyméthylmélamine (HMMM), l’épichlorophydrin (ECH), le triéthanolamine et le glycérol etc, Le HMMM et l’ECH ont donné dexcellentes propriétés de séchage. L’émulsification coopérative de (Span) sorbate et de (Tween) polyoxyéthylène sorbate pourrait améliorer la stabilité de la dispersione de HPPENK.

Similar content being viewed by others

References

Shi Y C, Y S Wu and Z Q Zhu, ‘Modification of aqueous acrylic-polyurethane via epoxy resin post-cross-linking’,J Appl Polym Sci,88, 470–5, May 2003

Subramani S, Y J Park and Y S Lee, ‘Polyurethane ionomer dispersions from a blocked aromatic-diisocyanate prepolymer’,Prog Org Coat,48, 71–9, June 2003

Anila A and W F Shi, ‘UV-curable water-borne polyurethane acrylate dispersions based on hyperbranched aliphatic polyester: Effect of molecular structure on physical and thermal properties’,Polym Adv Technol,15, 669–75, September 2004

Kim B K, J S Lee, M C Lee and K S Yoon, ‘Polyurethane-poly(methyl methacrylate) block copolymer dispersions through polyurethane macroiniferters’,J Appl Polym Sci,88, 1971–5, December 2003

Sebenik U, J Golob and M Krajnc, ‘Comparison of properties of acrylicpolyurethane hybrid emulsions prepared by batch and semibatch processes with monomer emulsion feed’,Polym Int,52, 740–8, January 2003

Deng S B, R Bai, and J P Chen, ‘Behaviors and mechanisms of copper adsorption on hydrolyzed polyacrylonitrile fibers’,Journal of Colloid and Interface Science,260, 265–72, October 2003

Sebenik U and M Krajnc, ‘Properties of acrylic polyurethane hybrid emulsions synthesized by the semibatch emulsion copolymerization of acrylates using different polyurethane particles’,J Polym Sci: Part A: Polym Chem,43, 4050–69, April 2005

Lu M G, J Y Lee, M J Shim and S W Kim, ‘Thermal degradation of film cast from aqueous polyurethane dispersions’,J Appl Polym Sci,85, 2552–8, November 2002

John H L R and W P Stephen, Imperial Chemical Industries, UK, EU Patent Application EP 32630, 11, 29th July 1981

Wang G Q, S H Zhang, D L Yang and X G Jian, ‘Preparation of a novel poly(phthalazinone ether nitrile ketone) ultrafiltration membrane: Effect of non-solvent additives’,Journal of Functional Polymers,18, (1), 105–9, June 2005

Yan Q L, J Y Wang, Z Y Liu, S Q Li and X G Jian, ‘The novel wire’,Wire Industry,72, (883), 177–80, July 2005

Wang G Q, X G Jian, S H Zhang, D L Yang and Y Su, ‘Preparation of poly(phthalazinone ether nitrile ketone) ultrafiltration membrane with low molecular weight cut-off’,Modern Chemical Industry,23, (7), 37–40, August 2003

Wang G Q, S H Zhang, D L Yang, C R Wu and X G Jian, ‘Study on the effect of evaporation on the performance of PPENK ultrafiltration membranes’,Membrane Science and Technology,25, (3), 18–21, February 2005

Wang R L, X G Jian and X L Zhu, ‘Synthesis and property of polyamides containing o-methyl phthalazone moieties’,Chinese J Appl Chem,18, (5), 404–7, May 2001

Sugahara Y and T Ohta, ‘Synthesis of starch-graft-polyacrylonitrile hydrolyzate and its characterization’,J Appl Polym Sci,82, 1437–43, October 2001

Krul’ L P, E I Nareiko, D V Krakodeev and E V Grinyuk, ‘13C NMR study of the structure of products formed in base hydrolysis of Nitron D polyacrylonitrile fiber’,Russian J Appl Chem,76, (6), 978–80, February 2003

Piao Y S, L J Mao and R H Sun, ‘Investigation on hydrolysis process of PAN by IR’,Journal of Wuxi University of Light Industry,19, (3), 276–8, May 2000

Chen P, Z P Tang and X J Wang, ‘Structure and property of co-curing reaction product for epoxy and cyanate resin system’,Chinese J Mater Res,18, (3), 265–72, June 2004

Wang J Y, S Liu and X G Jian, ‘Study on hydroxylation of poly(ether sulfone ketone) containing the phthalazinone moiety copolymer’,Polym Mater Sci and Eng,18, (2), 49–52, May 2002

Parmar R, K Patel and J Parmar, ‘High-performance waterborne coatings based on epoxy-acrylic-graft-copolymer-modified polyurethane dispersions’,Polym Int,54, 488–94, December 2005

Zhong Z S, ‘Application of Surfactant in Cosmetics. First version’,Peking Chemical Industry Press,78, August 2003

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Z.Y., Wang, J.Y., Yan, Q.L. et al. Study on novel heat-resistant aqueous dispersion based on modified poly(phthalazinone ether nitrile ketone)s. Surface Coatings International Part B: Coatings Transactions 89, 209–214 (2006). https://doi.org/10.1007/BF02699662

Issue Date:

DOI: https://doi.org/10.1007/BF02699662