Abstract

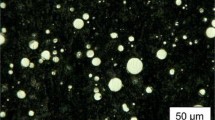

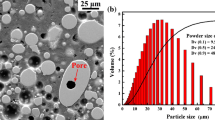

Microstructural characterization and electron diffraction crystal structure determinations have been carried out on the tool steel M2. Detailed examination using optical microscopy and thin-film and replica transmission electron microscopy substantiate preliminary findings.2,3 Namely, that laser melted material has a two-phase σ-ferrite/austenite matrix containing a dispersion of fine M2C carbides together with a smaller amount of M23C6 carbides. Subsequent heat treatment at 560 and 1230°C increases the hardness (to a maximum value of ∼1100 VHN) by carbide precipitation. In material heat treated at 560°C there is a preponderance of M23C6 carbides together with a small amount of M2C carbides. In contrast, the effect of heat treatment at 1230°C is to produce material containing only MC1-x type carbides with diameters in the range from 20 nm to ∼1 µm.

Similar content being viewed by others

References

E. M. Breinan, B. H. Kear, C. M. Banas, and L. E. Greenwald:Superalloys: Metallurgy and Manufacture, p. 435, 3rd International Symposium, Seven Spring, PA 1975.

P. R. Strutt, M. Tuli, H. Nowotny, and B. H. Kear:Mater: Sci. Eng., 1978, vol. 36, p. 217.

M. Tuli, P. R. Strutt, and B. H. Kear:Conference of Rapidly Solidifica- tion Processing, Reston, Virginia, Dec, 1977.

M. Tulli: Master Thesis, University of Connecticut, 1977.

L. E. Greenwald: Report R77-111321-1, United Technologies Research Center, East Hartford, Connecticut, 1977.

H. Matyja, B. C. Giessen, and N. J. Grant:J. Inst. Metals, 1968, vol. 9, p. 30.

I. R. Sare and R. W. K. Honeycome:2nd Int. Conference on Rapidly Quenched Metals, N. J. Grant and B. C. Giessen eds., M. I. T. Press, 1976.

J. J. Rayment and B. Cantor:Met. Sci., 1978, vol. 12, p. 156.

H. Fredrickson:Met. Sci., 1976, vol. 3, p. 77.

J. McLaughlin, R. W. Kraft, and J. I. Goldstein:Met. Trans A., 1977, vol. 8A, p. 1787.

R. H. Barkalow, R. W. Kraft, and J. I. Goldstein:Met. Trans., 1972, vol. 3, p.919.

C. J. Smithells:Metals Reference Book, vol. 2, p. 556, 1967.

Author information

Authors and Affiliations

Additional information

formerly with the Metallurgy Department, University of Connecticut

Rights and permissions

About this article

Cite this article

Kim, YW., Strutt, P.R. & Nowotny, H. Laser melting and heat treatment of m2 tool steel: A microstructural characterization. Metall Trans A 10, 881–886 (1979). https://doi.org/10.1007/BF02658307

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02658307