Abstract

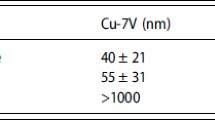

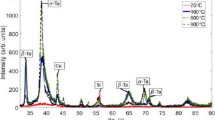

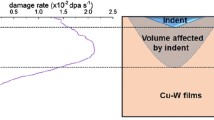

The possibility of producing nonequilibrium amorphous and crystalline phases in the Cu-W system is of interest because, under equilibrium conditions, no mutual solubility is expected between Cu and W. Triode sputtered coatings (45 to 150 μm thick, produced at deposition rates between 20 and 150 Å/s) consisted of amorphous and metastable crystalline phases. The latter remained decomposition-resistant on heating to various temperatures between 340 °C and 600 °C (the maximum temperature of exposure). The amorphous phase in such coatings crystallized on heating into a metastable body-centered cubic (bcc) phase, and the crystallization temperatureT x was found to decrease across the phase diagram from 450 °C to 340 °C as the percentage of W increased from 26 to 60 at. pct. Samples containing amorphous phase regions, when subjected to heating between 150 °C and 250 °C, showed an unusual rapid precipitation of Cu at the sample surface, indicating an easy diffusion of the Cu component. This occurred without crystallization of the remaining slightly tungsten-enriched amorphous matrix. Microhardness measurements in sputtered two-phase amorphous and bcc regions have shown that in alloys of the same composition, the amorphous phase was always softer than the bcc solid solution phase. X-ray, microprobe, and optical evidence suggests that the amorphous films deposited at very low temperatures(i.e., at liquid N2) may subsequently undergo a phase separation upon heating to room temperature and prior to crystallization. Earlier work and present studies of vapordeposited alloys in this system confirm that the observed phases and microstructures can be related to free energy trends estimated from thermodynamic considerations and to specific deposition parameters, such as the substrate temperature and the deposition rates, which influence the kinetics.

Similar content being viewed by others

References

H.F. Rizzo, T.B. Massalski, and E.D. McClanahan:Metall. Trans. A, 1988, vol. 19A, pp. 5–12.

H.F. Rizzo, L.E. Tanner, M.A. Wall, E.D. McClanahan, and T.B. Massalski: inFundamentals of Beam-Solid Interactions and Transient Thermal Processing, Materials Research Society Proceedings 100, M.J. Aziz, L.E. Rehn, and B. Stritzker, eds., Materials Research Society, Pittsburgh, PA, 1988, pp. 81–85.

H.F. Rizzo, A. Echeverria, T.B. Massalski, and H. Baxi:Mater. Res. Soc. Symp. Proc, 1989, vol. 128, pp. 231–36.

M. Nastasi, F.W. Saris, L.S. Hung, and J.W. Mayer:J. Appl. Phys., 1985, vol. 58(8), pp. 3052–58.

Han Westendorp, Zhong-Lie Wang, and Fran W. Saris:Nucl. Instrum. Methods, 1982, vol. 194, pp. 453–456.

Z.L. Wang, J.F.M. Westendorp, and F.W. Saris:Nucl. Instrum. Methods, 1983, vol. 209 210, pp. 115–24.

A. Schafer and G. Menzel:Thin Solid Films, 1978, vol. 52, pp. 11–21.

A.G. Dirks and J.J. van der Broek:J. Vac. Sci. Technol. 1985, vol. A3 (6), pp. 2618–22.

A.R. Miedema and A.K. Niessen:Suppl. to Trans. JIM, 1988, vol. 29, pp. 209–13.

T. Egami and Y. Waseda:J. Non-Cryst. Solids, 1984, vol. 64, pp. 113–34.

P.R. Subramanian and D.E. Laughlin: inPhase Diagrams of Binary Tungsten Alloys, S.V. Nagender Naidu and P. Rama Rao, eds., Indian Institute of Metals, Calcutta, 1991, pp. 76–79.

A.R. Miedema, P.F. de Chatel, and F.R. de Boer:Physica, 1980, vol. 100B, pp. 1–28.

T. Egami and S. Aur:J. Non-Cryst. Solids, 1987, vol. 89, pp. 60–74.

H.E. Kissinger:Anal. Chem., 1957, vol. 29, 1702–06.

B. Cantor and R.W. Cahn:Acta Metall., 1976, vol. 24, pp. 845–52.

N. Saunders and A.P. Miodownik:J. Mater. Sci., 1987, vol. 22, pp. 629–37.

N. Gjostein: inSurfaces and Interfaces I —Chemical and Physical Characteristics J.J. Burke, N.L. Reed, and V. Weiss, eds., Syracuse University Press, Syracuse, NY, 1982, pp. 271–304.

Kubaschewski and C.B. Alcock:Metallurgical Thermochemistry, 5th ed., Pergamon Press, 1978, pp. 359–75.

G. Edrlich and F.G. Hudda:J. Chem. Phys., 1966, vol. 44, pp. 1039–49.

G. Veltl, B. Scholtz, and H.-D. Kunze:Mater. Sci. Eng., 1991, vol. A134, pp. 1410–14.

E. Hellstern, H.J. Fecht, Z. Fu, and W.L. Johnson:J. Appl. Phys., 1989, vol. 65, pp. 305–10.

K. Sakurai, Y. Yamada, C.H. Lee, T. Fukunaga, and U. Mizutani:Mater. Sci. Eng. 1989, vol. A134, pp. 1414–17.

E. Gaffet, C. Louison, M. Hamerlin, and F. Faudot:Mater. Sci. Eng., 1991, vol. A134, pp. 1380–84.

Author information

Authors and Affiliations

Additional information

Leave from the Department of Materials Science, Carnegie Mellon University, Pittsburgh, PA 15213

Rights and permissions

About this article

Cite this article

Rizzo, H.F., Massalski, T.B. & Nastasi, M. Metastable crystalline and amorphous structures formed in the Cu-W system by vapor deposition. Metall Trans A 24, 1027–1037 (1993). https://doi.org/10.1007/BF02657233

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02657233