Abstract

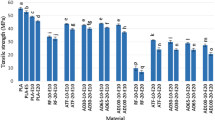

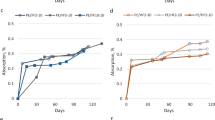

The surfaces of henequen fibers, which can be obtained from the leaves of agave plants, were treated with two different media, tap water and sodium hydroxide, that underwent both soaking and ultrasonic methods for the fiber surface treatment. Various biocomposites were fabricated with untreated and treated, chopped henequen fibers and polypropylene using a compression molding method. The result is discussed in terms of interfacial shear strength, flexural properties, dynamic mechanical properties, and fracture surface observations of the biocomposites. The soaking (static method) and ultrasonic (dynamic method) treatments with tap water and sodium hydroxide at different concentrations and treatment times significantly influenced the interfacial, flexural and dynamic mechanical properties of henequen/polypropylene biocomposites. The alkali treatment was more effective than the water treatment in improving the interfacial and mechanical properties of randomly oriented, chopped henequen/PP biocomposites. In addition, the application of the ultrasonic method to each treatment was relatively more effective in increasing the properties than the soaking method, depending on the treatment medium and condition. The greatest improvement in the properties studied was achieved by ultrasonic alkalization of natural fibers, which was in agreement with the other results of interfacial shear strength, flexural strength and modulus, storage modulus, and fracture surfaces.

Similar content being viewed by others

References

A. K. Mohanty, M. Misra, and G. Hinrichsen,Macromol. Mater. Eng.,276/277, 1 (2000).

D. Cho, S. G. Lee, W. H. Park, and S. O. Han,Polym. Sci. Technol.,13, 460 (2002).

A. K. Rana, A. Mandal, and S. Bandyopadhyay,Compos. Sci. Technol.,63, 801 (2003).

T. Nishino, K. Hirao, M. Kotera, K. Nakamae, and H. Inagaki,Compos. Sci. Technol.,63, 1281 (2003).

L. M. Arzondo, C. J. Perez, and J. M. Carella,Polym. Eng. Sci.,45, 613 (2005).

K. C. M. Nair, S. Thomas, and G. Groeninckx,Compos. Sci. Technol.,61, 2519 (2001).

Y. Pang, D. Cho, S. O. Han, and W. H. Park,Macromol. Res.,13, 453 (2005).

G. C. Yang, H. M. Zeng, and J. J. Li,Fiber Reinf. Plastics Compos.,3, 12 (1997).

M. Aguilar-Vega and C. A. Cruz-Ramos,J. Appl. Polym. Sci.,58, 1245 (1995).

G. Canche-Escamillar, J. Rodriguez-Laviada, J. I. Cauich-Cupul, E. Mendizabal, J. E. Puig, and P. J. Herrera-Franco,Composites Part A,33, 539 (2002).

P. J. Herrera-Franco and A. Valadez-Gonzalez,Composites Part B,36, 597 (2005).

S. O. Han, D. Cho, W. H. Park, and L. T. Drzal,Compos. Interfaces,12(2/3), 231 (2006).

C. K. Kum, Y. T. Sung, and Y. S. Kim,et al., Macromol. Res.,15, 308 (2007).

J. C. Kim and J. H. Chang,Macromol. Res.,15, 449 (2007).

A. C. N. Singleton, C. A. Baillie, P. W. R. Beaumont, and T. Peijs,Composites Part B,34, 519 (2003).

A. K. Mohanty, M. Misra, and L. T. Drzal,Compos. Interfaces,8, 313 (2001).

L. Y. Mwaikambo and M. P. Ansell,Die Angew. Makromol. Chem.,272, 108 (1999).

S. Joseph, M. S. Sreekala, Z. Oommen, P. Koshy, and S. Thomas,Compos. Sci. Technol.,62, 1857 (2002).

A. Arbelaiz, G. Cantero, B. Fernandez, I. Mondragon, R. Ganan, and J. M. Kenny,Polym. Compos.,26, 324 (2005).

S.-H. Lee and S. Wang,Composites Part A,37, 80 (2006).

X. Yuan, K. Jayaraman, and D. Bhattacharyya,J. Adhesion Sci. Technol.,18, 1027 (2004).

D. Cho, S. M. Lee, S. G. Lee, and W. H. Park,Am. J. Appl. Sci., Special Issue (Bio-compat. Bio-compos. Mater.), 17 (2006).

(23) R. P. Brown, Ed.,Handbook of Plastics Test Methods, 3rd Ed., Longman Scientific & Technical, London, 1998, Chapter 8.

D. Cho, S. B. Yoon, J. M. Seo, S. O. Han, and W. H. Park,Proc. (CD) 12 th Int’l Conf. Compos. Eng./Nano (ICCE-12), August 1-6, Tenerife, Spain, 2005.

J. M. Seo, D. Cho, W. H. Park, S. O. Han, T. W. Hwang, C. H. Choi, S. J. Jung, and C. S. Lee,J. Biobased Mater. Bioenergy,1, 331 (2007).

M. Z. Rong, M. Q. Zhong, Y. Liu, G. G. Yang, and H. M. Zheng,Compos. Sci. Technol.,61, 1437 (2001).

A. O’Donnell, M. A. Dweib, and R. P. Wool,Compos. Sci. Technol.,64, 1135 (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, H.S., Cho, D. & Han, S.O. Effect of natural fiber surface treatments on the interfacial and mechanical properties of henequen/polypropylene biocomposites. Macromol. Res. 16, 411–417 (2008). https://doi.org/10.1007/BF03218538

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF03218538