Abstract

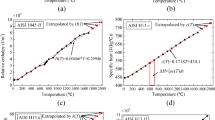

Temperature field and cooling rate are important parameters to influence the properties of clad layer and the heat affected zone. In this paper the temperature field and cooling rate of laser cladding are studied by a two-dimensional time-dependent finite element model. Experiment has been carried out by Nd:YAG laser cladding with wire feeding. Research results indicate that at the beginning of cladding, the width and depth of melt pool increase with cladding time. The cooling rate is related to position, cladding time, cladding speed, and preheating temperature. The temperature near melt pool changes rapidly while the temperature far from melt pool changes slowly. With the increase of cladding time, cooling rate decreases. The further the distance from the melt pool, the lower the temperature and the slower the cooling rate. The faster the cladding speed, the faster the cooling rate. The higher the preheating temperature, the slower the cooling rate. The FEM results coincide well with the experiment results.

Similar content being viewed by others

References

Agrawal, G., Kar, A. and Mazumder, J., 1993,Scripta Metallurgic et Materialia 28, (11), pp. 1453–1458.

Atamert, S., and Bhadeshia, H. K. D. H., 1989,Metall. Trans. A 20A, (6), pp. 1037–1054.

Bamberger, M., Kaplan, W. D., Medres, B. 1998,J. Laser Appl., Vol. 10, No. 1, pp. 29–33.

Chan, C., Mazumder, J. and Chen, M. M., 1984,Metall. Trans. A, Vol. 15A, pp. 2175–2184.

Damborene, J. J., Vazquez, A. J., Lopez, V.Processing of Advanced Materials Vol. 3, No. 2, pp. 107–113, ISSN: 0960-314X.

David, S. A. and Vitek, J. M., 1989,Int. Mater. Rev., vol. 34, pp. 213–45.

Denney, P. E. and Duhamel, R., 1998,Industrial Laser Review, November pp. 19–21.

Fouquet, F., Sallamand, P., Millet, J. P. 1994,J. Phys. (France) IV4, (C4), pp. 89–92.

Frenk, A., Henchoz, N., and Kurz, W.,Zeitschrift Fur Metallkunde 84, (12), pp. 886–892, Dec. 1993. ISSN: 0044-3093.

Hirose, A., Kohno, W., Nomura, D. 1992,Tetsu-To-Hagane (Journal of the Iron and Steel Institute of Japan) Vol. 78, No. 10, pp. 1585–1592.

Hoadley, A. F. A. and Rappaz, M., 1992,Metall. Trans. B, Vol. 23B, pp. 631–642.

Kar, A. and Mazumder, J., 1988,Acta Metall. Vol. 36, No. 3, pp. 701–712.

Kar, A. and Mazumder, J., 1989,Metall. Trans. A, Vol. 20A, pp. 363–371.

Koshy, P., 1985, Conference: Applications of High Power Lasers, Los Angeles, California, USA, 22–23 Jan. 1985; Publ: SPIE, The International Society for Optical Engineering, P. O. Box 10, Bellingham, Washington 98227-0010, USA, pp. 80–85.

Li, L. J. and Mazumder J., 1984,Laser Processing of Materials (edited by Mukherjee, K. and Mazumder, J.), pp. 35–50. Proc. Metal. Soc. AIME, Los Angeles, Calif.

Liu, Y., Mazumder, J. and Shibata, K., 1994,Metall. Mater. Trans. B 25B, No. 5, pp. 749–759.

Mazumder, J. and Kar, A., 1987,J. Met. Vol. 39, No. 2, pp. 18–23.

Mohanty, P. S., and Mazumder, J., 1998,Metall. Mater. Trans. B, Vol. 29B, pp. 1269–1279.

Ono, M., Kosuge, S., Nakada, K. 1987, Conference: LAMP’87: Laser Advanced Materials Process-Science and Applications, Osaka, Japan, 21–23 May 1987; Publ: High Temperature Society of Japan, c/o Welding Research Institute of Osaka University, 11-1 Mihogaoka, Ibaraki, Osaka 567, Japan, pp. 395–400.

Picasso, M., Marsden, C. F., Wagniere, J. D. 1994,Metall. Mater. Trans. B, Vol. 25B, pp. 281–291.

Powell, J., Henry, P. S. and Steen, W. M., 1988,Surf. Eng. Vol. 4, No. 2, pp. 141–149.

Ramous, E., 1989, Conference: Surface Engineering With High Energy Beams: Science and Technology, Lisbon, Portugal, 25–27 Sept. 1989; Publ: CEMUL, Av. Rovisco Pais, 1096 Lisboa Codex, Portugal, pp. 425–433.

Tosto, S., Pierdominici, F. and Bianco, M., 1994,J. Mater. Sci. Vol. 29, No. 2, pp. 504–509.

Uenishi K. and Kobayashi, K. F., 1993,Kei Kinzoku Yosetsu (Journal of Light Metal Welding and Construction) Vol. 31, No. 4, pp. 1–5.

Yang, X., Zheng, T., Zhang, N. 1992.Acta Metallurgica Sinica (China) Vol. 28, No. 2, pp. B84-B88, Feb. ISSN: 0412-1961.

Yellup, J. M., 1995,Surf. Coat. Technol. Vol. 71, No. 2, pp. 121–128, ISSN: 0257-8972.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JD., Peng, Y. Temperature field and cooling rate of laser cladding with wire feeding. KSME International Journal 14, 851–860 (2000). https://doi.org/10.1007/BF03184473

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03184473