Abstract

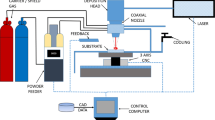

As a promising and novel manufacturing technology, laser aided direct metal deposition (DMD) process produces near-net-shape functional metal parts directly from 3-D CAD models by repeating laser cladding layer by layer. The key of the build-up mechanism is the effective control of powder delivery and laser power to be irradiated into the melt-pool. A feedback control system using two sets of optical height sensors is designed for monitoring the melt-pool and real-time control of deposition dimension. With the feedback height control system, the dimensions of part can be controlled within designed tolerance maintaining real time control of each layer thickness. Clad nugget shapes reveal that the feedback control can affect the nugget size and morphology of microstructure. The pore/void level can be controlled by utilizing pulsed-mode laser and proper design of deposition tool-path. With the present configuration of the control system, it is believed that more innovation of the DMD process is possible to the deposition of layers in 3-D slice.

Similar content being viewed by others

References

Choi, J. and Chang, Y., 2005, “Characteristics of Laser Aided Direct Metal/Material Deposition Process for Tool Steel,”International Journal of Machine Tools & Manufacture, Vol. 45, pp. 597–605.

Choi, J. and Mazumder, J., 1994, “Synthesis of Fe-Cr-C-W Using Laser Cladding Technique,”Journal of Material Science, Vol. 29, No. 17, pp. 4460–4476.

Choi, J. and Mazumder, J., 2001, “Rapid Manufacturing by Laser Aided Direct Metal Deposition Process: Issues and Examples,” DETC2001/ DAC-21043, Proceedings of DETC’01, ASME, Pittsburgh, PA.

Jee, H. S., 2002, “Die Manufacturing and Repair Using Laser-Aided Direct Metal Tooling,”CAD/CAM, Vol. 8, No. 2, pp. 47–52.

Koch, J. L. and Mazumder, J., 2000, US Patent #6,122,564.

Kulkarni, P. and Dutta, D., 1996, “An Accurate Slicing Procedure for Layered Manufacturing,”Computer-Aided Design, Vol. 28, No. 9, pp. 683–697.

Marabella, L., 1996, “Precision Laser Machining Using Diode Pumped Solid State Lasers,”Laser Treatment of Materials, ECLA T ’96, Vol. 1, pp. 3–10.

Matsunawa, A., 2001, “Problems and Solutions in Deep Penetration Laser Welding,”Sci. Tech. Weld. Joining, Vol. 6, pp. 351–354.

Mazumder, J., Koch, J., Nagarathnam, K. and Choi, J., 1996, “Rapid Manufacturing by Laser Aided Direct Deposition of Metals,”Advances in Powder Metallurgy and Particulate Materials, part 15, MPIF, pp. 107–118.

Mazumder, J., Choi, J., Nagarathnam, K., Koch, J. and Hetzner, D., 1997, “The Direct Metal Deposition of H13 Tool Steel for 3-D Components,”JOM-Journal of the Minerals Metals & Materials Society, Vol. 49, No. 5, pp. 55–60.

Mazumder, J., Schifferer, A. and Choi, J., 1999, “Direct Materials Deposition: Designed Macro and Microstructure,”Materials Research Innovations, Vol. 3, No. 3, pp. 118–131.

Mazumder, J., 2000, “A Crystal Ball View of Direct-metal Deposition,”JOM-Journal of the Minerals Metals & Materials Society, Vol. 52, No. 12, pp. 28–29.

Roberts, G., Krauss, G. and Kennedy, R., 1998,Tool Steels Handbook, 5th edition, ASM International, Materials Park, OH.

Steen, W. M., 1998,Laser Material Processing, 2nd ed., Springer-Verlag, p. 131.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, J., Chang, Y. Analysis of laser control effects for direct metal deposition process. J Mech Sci Technol 20, 1680–1690 (2006). https://doi.org/10.1007/BF02916272

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02916272