Abstract

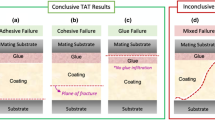

Tensile adhesion tests (TATs) which are normally utilized for industrial quality control procedures have been used for research purposes to examine failure mechanisms of plasma sprayed coatings. This work is applied to two layer coatings (NiCrAlY or NiCrAlZr bond coat with a yttria stabilized zirconia ceramic overlay) which are tested in tension perpendicular to the surface. The mechanical behavior of the bond coat and ceramic overlay were not measured separately. However, the specific component of the coating which sustains the major deformation is related to the failure locus and enables an empirical determination of the bond coat and ceramic overlay deformations to be postulated.

It has been determined that adhesive failure within the bond coat exhibits greater failure strain than cohesive failure of the ceramic overlay. This view lends support to the commonly accepted understanding of these intermediate coatings being highly compliant. The absolute extension exhibited by failures which occur only through the ceramic coating (i.e., cohesive failure) is greater than that of adhesive failure because the ceramic coating is much thicker than the bond coat.

The stress vs. extension data can be expressed in terms of stress vs. strain, and hence the modulus of the coating components approximated to be about 100 MPa. This value is several orders in magnitude lower than that previously reported in the literature and the technical reasons for this discrepency are discussed.

Similar content being viewed by others

References

ASTM C633-69: “Standard Method for Adhesion or Cohesive Strength of Flame-Sprayed Coatings,” American Society for Testing and Materials, Philadelphia, 1969.

F.J. Hermanek: “Determining the Adhesive Cohesive Strength of Thin Thermally Sprayed Deposits,”Weld J., 1978, Vol. 57, pp. 31–35.

R.A. Miller and C.E. Lowell: “Failure Mechanisms of Thermal Barrier Coatings Exposed to Elevated Temperatures,”Thin Solid Films, 1982, Vol. 95, pp. 265–274.

P. Ostojic and C.C. Berndt: “The Variability in Strength of Thermally Sprayed Coatings,”Surface and Coatings Technology, 1988, Vol. 34, pp. 43–50.

R.A. Miller: “Oxidation-Based Model for Thermal Barrier Coating Life,”Am. Ceram. Soc. J., 1984, Vol. 67, No. 8, pp. 517–521.

R.M. Shankar, C.C. Berndt, and H. Herman: “Characterization of the Mechanical Properties of Plasma-Sprayed Coatings,”Mater. Sci. Res., 1983, Vol. 15, pp. 473–490.

P. Boch, D. Fargeot, C. Gault, and F. Platon: “Variations of the Elastic Moduli of Alumina during Structural Phase Transition,” Rev. Int. Hautes Temper. et Refract., 1981, Vol. 18, pp. 85–93.

J.C. Glandus, F. Platon, and P. Boch: “Measurements of the Elastic Moduli of Ceramics,”Materials in Engineering Applications, 1979, Vol. 1, pp. 243–246.

P.A. Siemers and R.L. Mehan: “Mechanical and Physical Properties of Plasma Sprayed Stabilized Zirconia,”Ceram. Eng. Sci. Proc., 1983, Vol. 4, No. 9–10, pp. 828–840.

P.A. Siemers and W.B. Hillig: “Thermal-Barrier-Coated Turbine Blade Study,” Final Report, NASA CR-165351, August, 1981, 123 pages.

R.C. Hendricks, G. McDonald, and R.L. Mullen: “Residual Stress in Plasma-Sprayed Ceramic Turbine and Gas-Path Seal Specimens,”Ceramic Eng. and Sci. Proc., 1983, Vol. 4, No. 9–10, pp. 802–809.

N.R. Shankar, C.C. Berndt, and H. Herman: “Failure and Acoustic Emission Response of Plasma-Sprayed ZrO2-8 wt% Y2O3,”Ceram. Eng. Sci. Proc., 1982, Vol. 3, No. 9–10, pp. 772–792.

C.C. Berndt and Y.H. Yi: “The Manufacture and Microstructure of Fiber Reinforced Thermally Sprayed Coatings,”Surface Coatings and Technology, 1989, Vol. 37, pp. 89–110.

C.C. Berndt and R. McPherson: “The Adhesion of Plasma Sprayed Ceramic Coatings to Metals,”Mater. Sci. Res., 1981, Vol. 14, pp. 619–628.

P.C. Hopman: “The Direct Pull-Off Test,”JOCCA, 1984, Vol. 7, pp. 179–184.

J. Sickfeld: “Pull-Off Test, an Internationally Standardized Method for Adhesion Testing—Assessment of the Relevance of Test Results,” pp. 543–567 Adhesion Aspects of Polymeric Coatings. K.L. Mitall (Ed.), Plenum, New York, 1983.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Berndt, C.C. Instrumented tensile adhesion tests on plasma sprayed thermal barrier coatings. J. Mater Eng. 11, 275–282 (1989). https://doi.org/10.1007/BF02834137

Issue Date:

DOI: https://doi.org/10.1007/BF02834137